Maintenance and regeneration device and maintenance regeneration method for lithium slurry battery

A technology for slurry batteries and regeneration equipment, which is applied in electrolyte/reactant regeneration, secondary battery repair/maintenance, battery pack components, etc., and can solve problems such as decreased cycle life, battery flatulence, and reduced battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

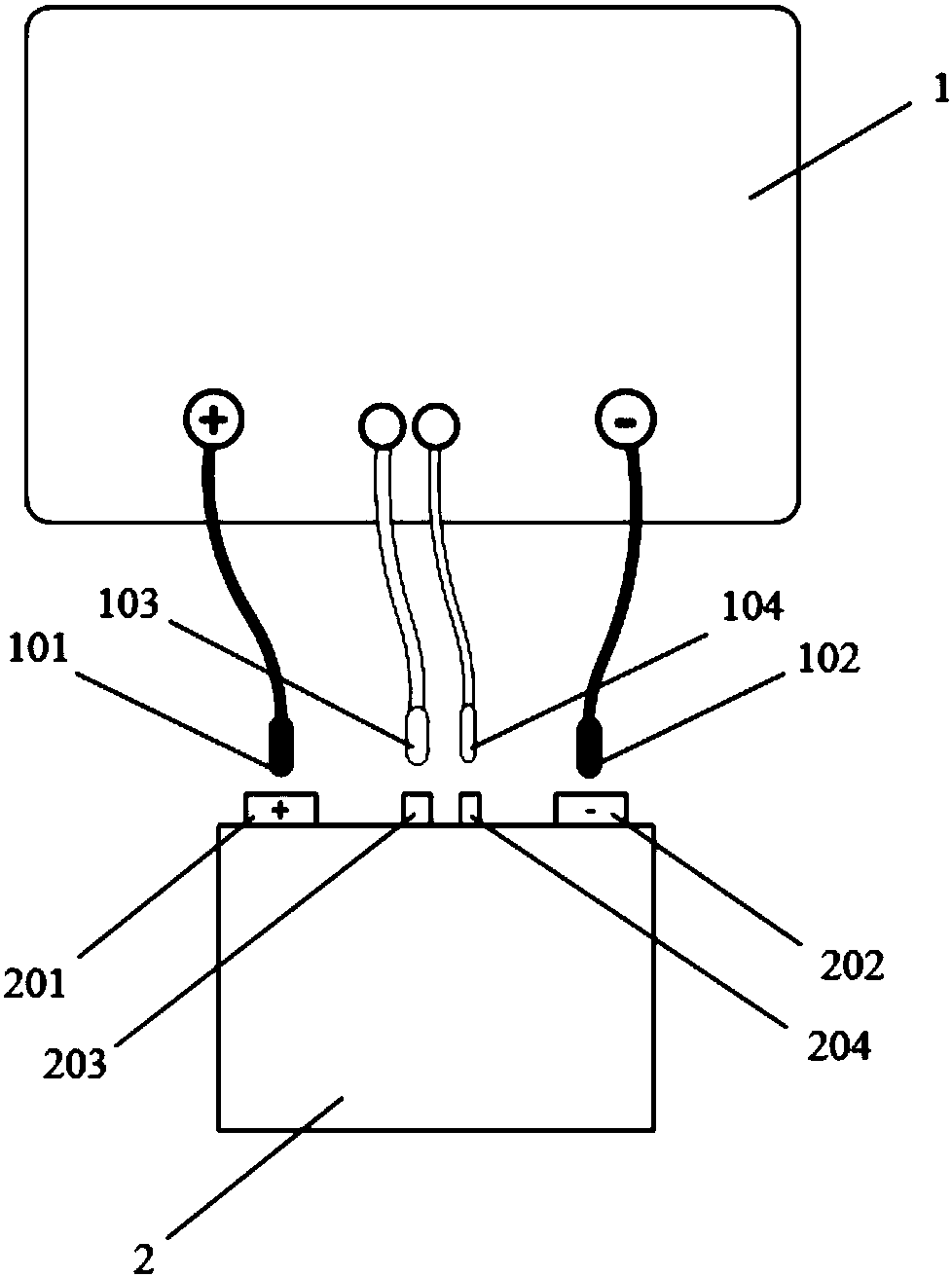

[0076] figure 1 It is a schematic diagram of the lithium slurry battery maintenance and regeneration equipment and the lithium slurry battery according to the present invention. The positive terminal 101 and the negative terminal 102 of the maintenance regeneration device 1 can be electrically connected to the positive terminal 201 and the negative terminal 202 of the lithium slurry battery 2 respectively, so as to charge and discharge the lithium slurry battery 2 . The gas nozzle 103 and the liquid nozzle 104 of the maintenance regeneration device 1 can be respectively connected with the gas port 203 and the liquid port 204 of the lithium slurry battery 2, so as to realize the injection, replenishment, liquid replacement, gas injection and discharge of the lithium slurry battery. Gas and other maintenance work.

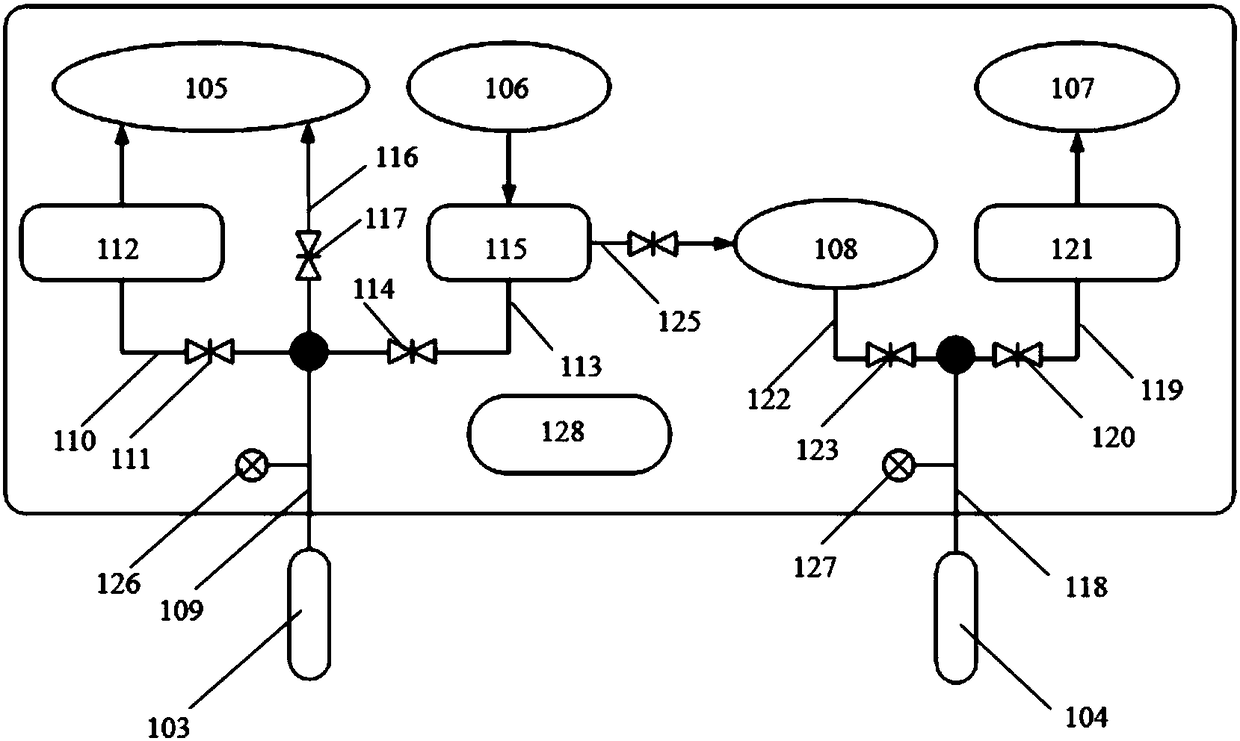

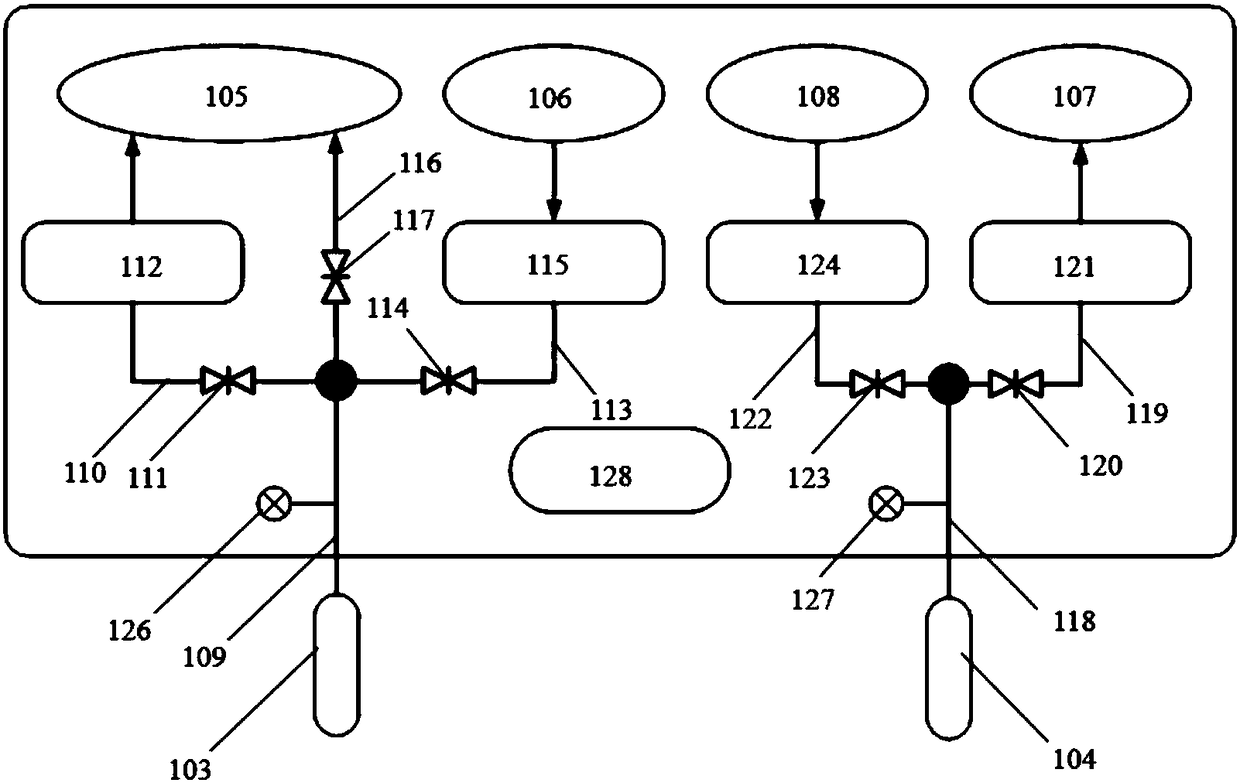

[0077] figure 2 It is a schemat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com