Five-axis ganged automatic numeric-control tool sharpener

A CNC knife sharpener and five-axis linkage technology, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problem that the automatic CNC knife sharpener cannot effectively control the grinding wheel, Affecting the production and application promotion of complex edge-shaped tools, inability to process high-precision complex edge-shaped alloy tools, etc., to achieve the effect of good market application prospects, easy learning and operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

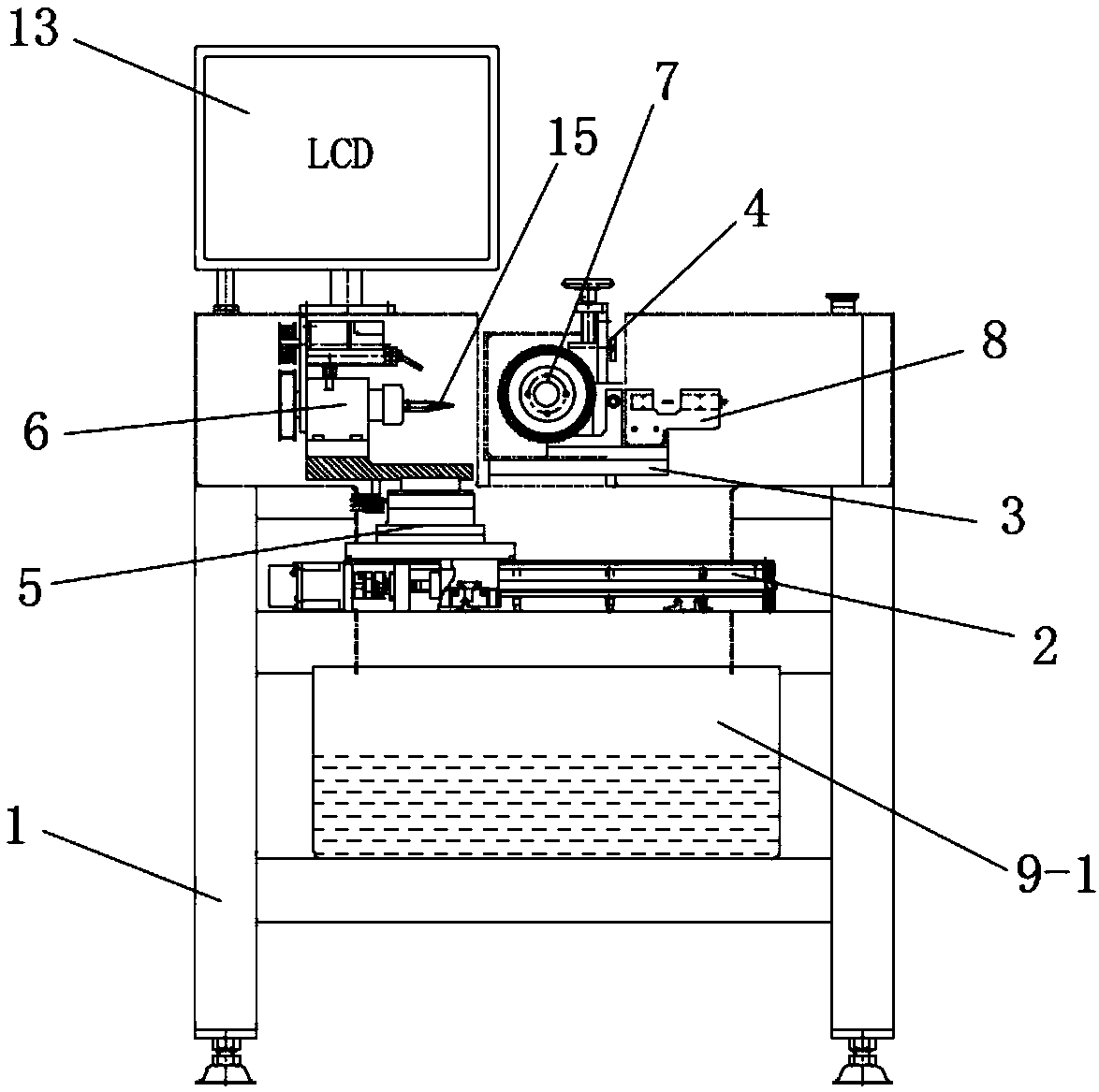

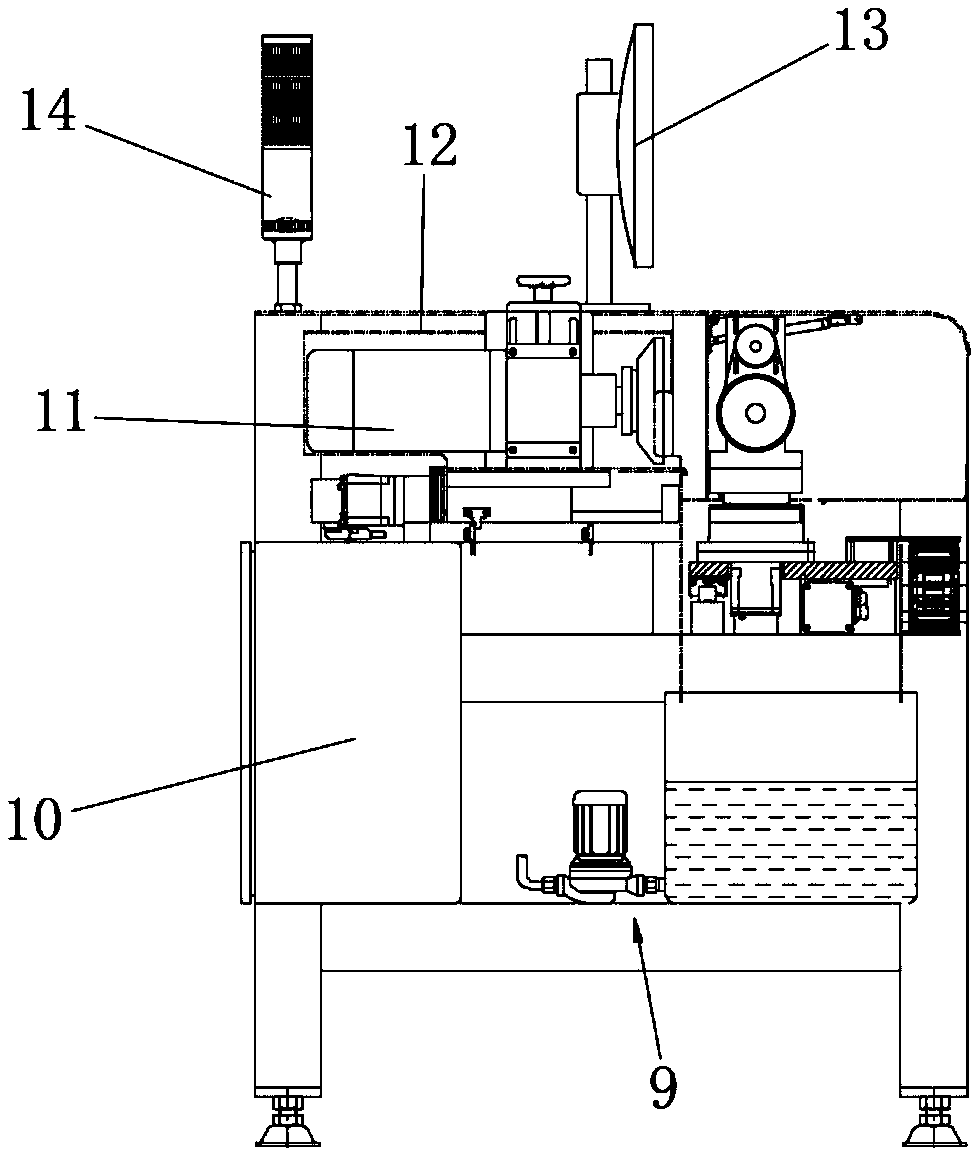

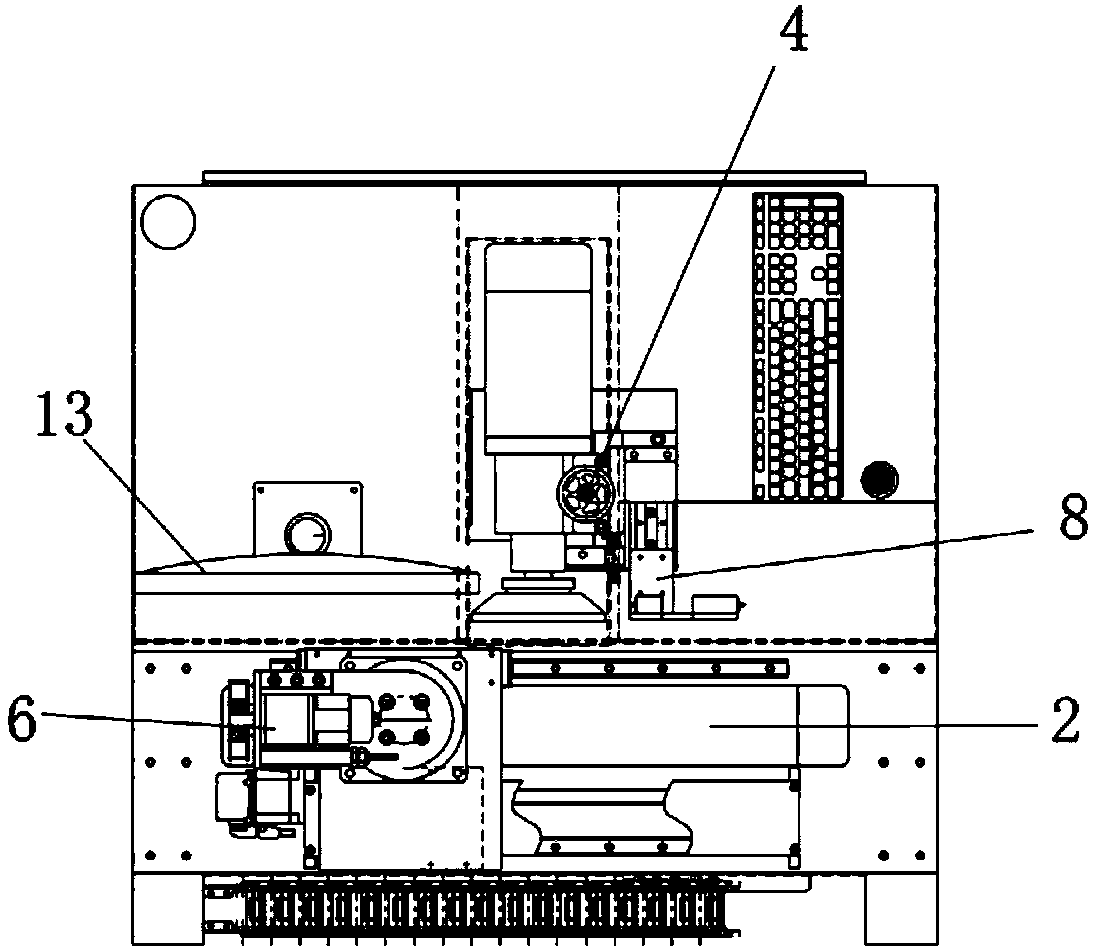

[0071] Such as Figure 1-6 As shown, this embodiment provides a five-axis linkage automatic CNC sharpening machine, including a frame 1, an X-axis sliding table 2, a Y-axis sliding table 3, a Z-axis lifter 4, a C-axis rotating table 5, and an A-axis Rotary fixture 6, grinding wheel power assembly 7, tool parameter detection mechanism 8, cooling module 9, protection module and electrical control cabinet 10. Wherein, the X-axis sliding table 2 and the Y-axis sliding table 3 are both arranged on the frame 1 and distributed in a "T" shape.

[0072] The C-axis rotating table 5 is arranged on the X-axis sliding table 2, the C-axis is vertically arranged and perpendicular to the X-axis, and the C-axis rotating table 5 moves along the X-axis driven by the X-axis sliding table 2 The A-axis rotary fixture 6 is arranged on the C-axis rotary table 5, the A-axis is arranged horizontally and perpendicular to the C-axis, and the A-axis rotary fixture 6 is driven by the C-axis rotary table 5...

Embodiment 2

[0121] Such as Figure 31-34 As shown, this embodiment is based on Embodiment 1, and the Z-axis lifter 4 is improved to make it an automatic lifter. The Z-axis lifter 4 includes: a horizontal bottom plate 4-1, a vertical groove plate 4-2, a rib plate 4-9, a spindle clamp seat 4-3, a Z-axis slide table 4-10, and a Z-axis screw motor mounting seat 4 -11. Trapezoidal screw rod 4-6, Z-axis linear guide rail 4-12, slider 4-13, ball screw nut support 4-14, gas spring 4-15, Z-axis servo motor 4-16. The Z axis servo motor 4-16 is electrically connected with the electrical control cabinet 10.

[0122] The horizontal base plate 4-1 is located at the bottom of the module, the vertical slot plate 4-2 is fixed on the horizontal base plate 4-1, the rib plate 4-9 is perpendicular to the vertical slot plate 4-2, and its bottom is fixed to the horizontal base plate 4-1 The connection plays the role of auxiliary reinforcement and fixation. The Z-axis slide table 4-10 is installed on the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com