Steel dam structure for water environment treatment

A water environment and steel dam technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of increased maintenance and maintenance costs, loss of the function of steel dams, and siltation of steel dams, so as to achieve economical and cost-effective maintenance and maintenance. The probability of deformation, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

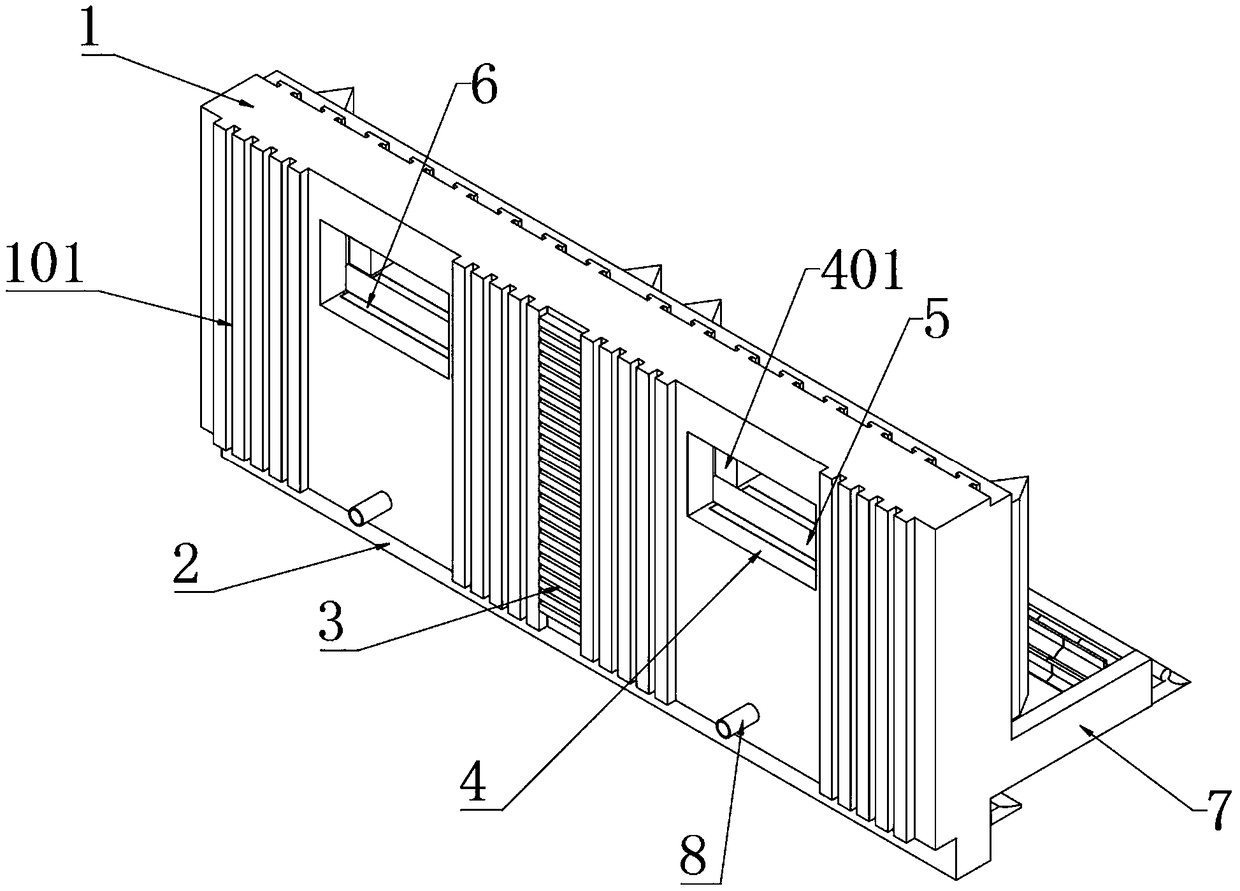

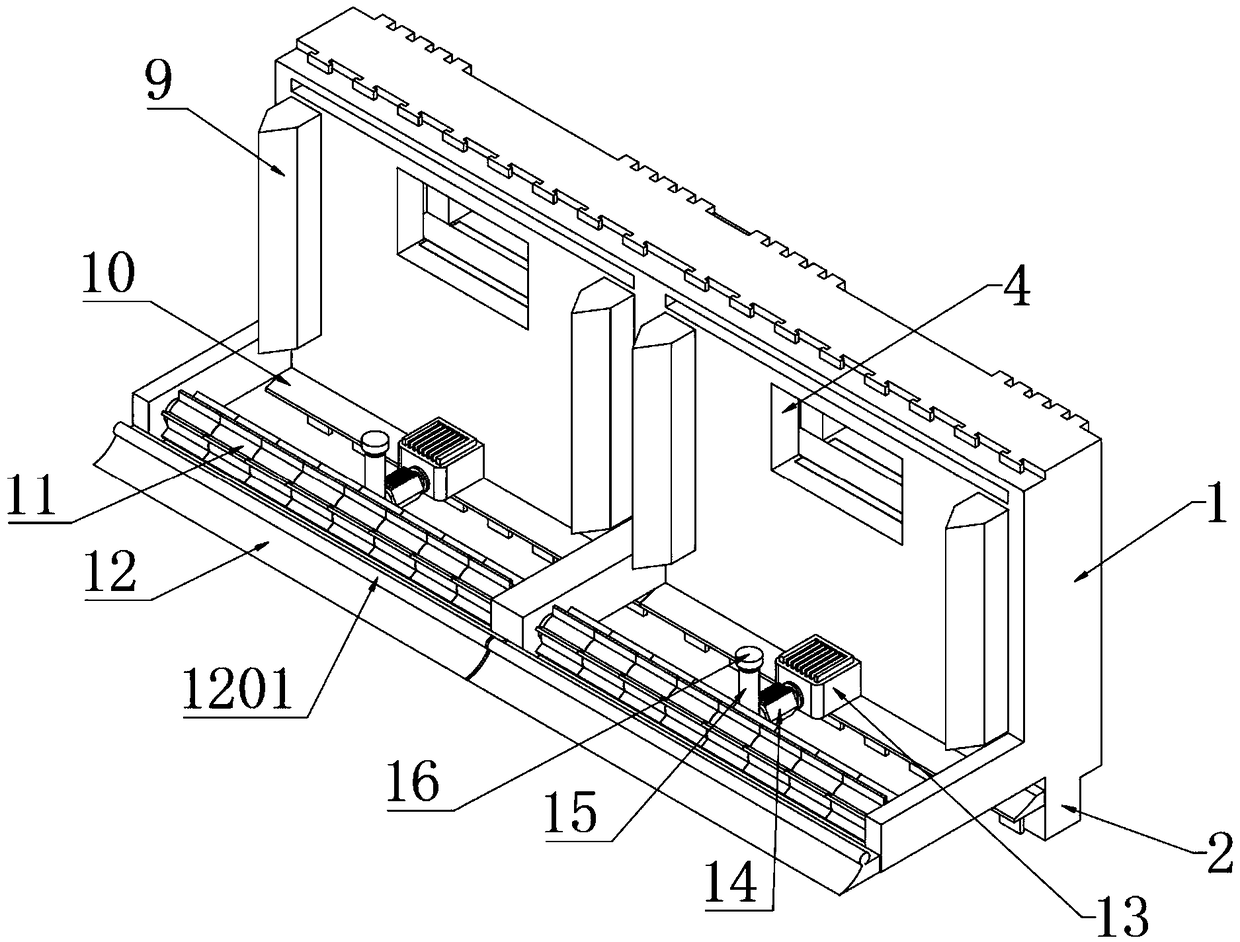

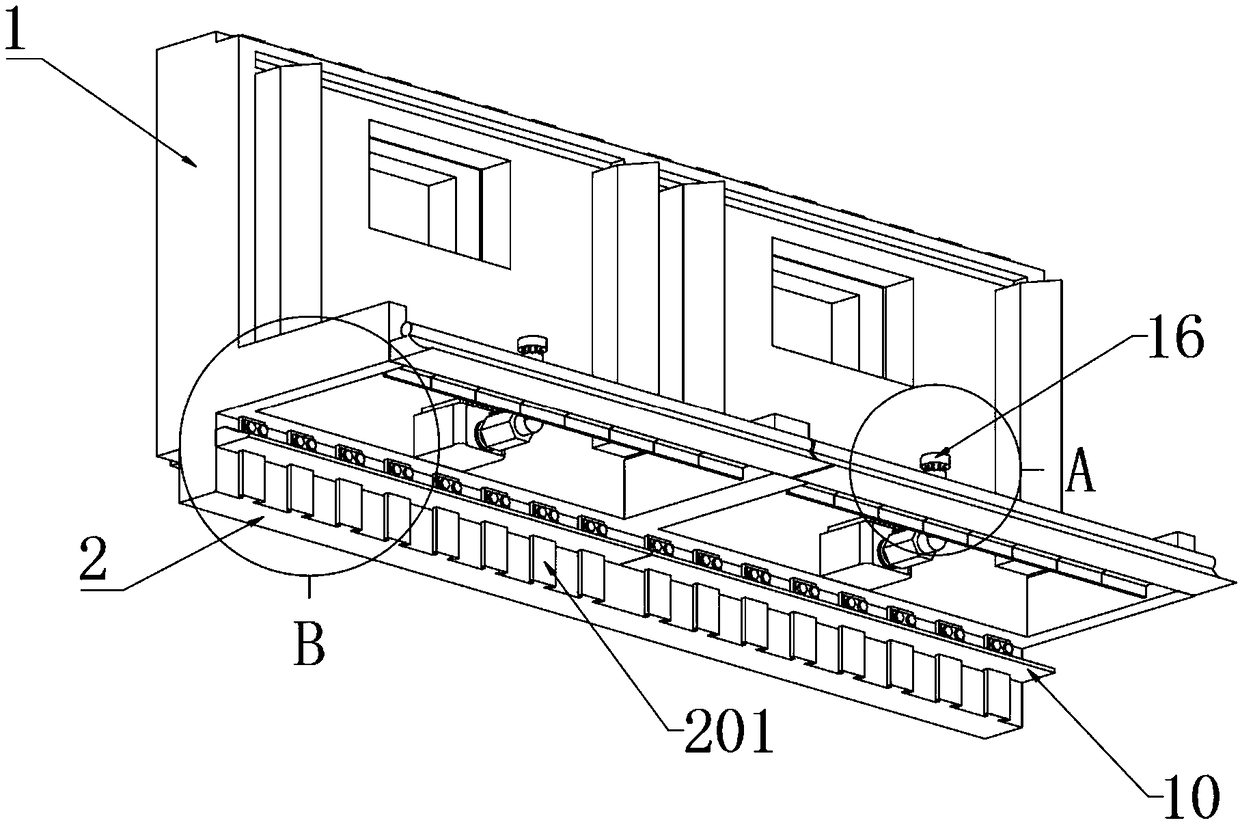

[0040] as attached figure 1 to attach Figure 13 Shown:

[0041] The present invention provides a steel dam structure for water environment treatment, including a steel dam main body 1, a reinforcement column 101, a steel dam lower inlay 2, a T-shaped slide rail 201, a welding connection column 3, an overflow port 4, an inner gate movable groove 401, an inner Gate 5, bottom groove 501, drainage hole 502, outer gate 6, limit block 601, connecting block 602, lug plate 7, drain pipe 8, water diversion body 9, level block 10, fixed plate 1001, power paddle 11 , mud-water separator 12, water pump 13, water inlet solenoid valve 14, water inlet pipe 15, water inlet head 16, support connecting column 1601, outer gate movable groove 17, water-stop rubber 1701, water injection pipe 18, water injection solenoid valve 19 and drainage Solenoid valve 20; the left end and the right end of the front side wall of the steel dam main body 1 are vertically welded with reinforcing columns 101; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com