Fe-Mn-Al-C series cold-rolled automobile steel and preparation method

A fe-mn-al-c, automobile technology, applied in the field of material processing, can solve the problems of difficult large-scale industrial production, high production cost, difficult smelting, etc., to improve yield strength and tensile strength, improve strength, The effect of excellent elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A Fe-Mn-Al-C series cold-rolled steel for automobiles, the chemical composition of the steel is as follows: Mn is 12.87wt.%, Al is 7.60wt.%, C is 0.72wt.%, P< 0.005%, S<0.002, and the rest are Fe and unavoidable impurities.

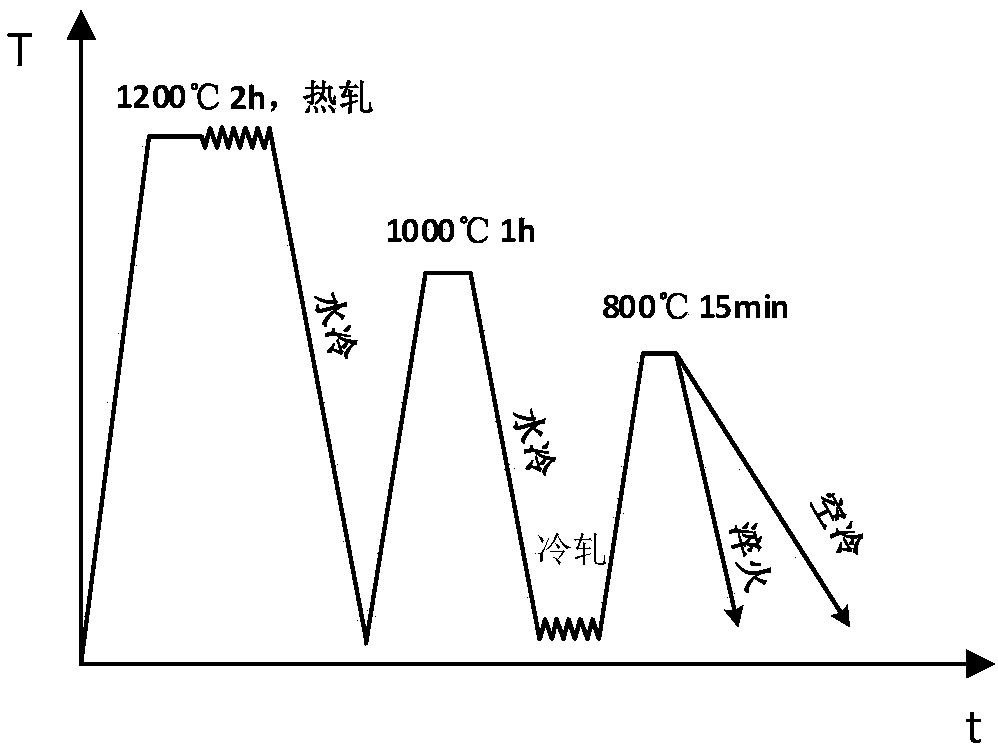

[0043] The preparation method of the above-mentioned Fe-Mn-Al-C series cold-rolled automobile steel comprises the following steps:

[0044] Step 1, smelting:

[0045] According to the composition ratio of Fe-Mn-Al-C series cold-rolled automobile steel, it is smelted in a vacuum induction melting furnace and cast to obtain an ingot;

[0046] Step 2, forging:

[0047] (1) Heat the billet to 1200°C and keep it warm for 2 hours;

[0048] (2) forging the ingot billet after heat preservation, air cooling to room temperature to obtain the forged billet, and cutting the billet to obtain a 35mm×120mm square billet;

[0049] Step 3, hot rolling:

[0050] (1) Heat the billet at 1200°C for 2 hours;

[0051] (2) heat-rolling the ingot billet after heat pr...

Embodiment 2

[0060] A Fe-Mn-Al-C series cold-rolled steel for automobiles, the chemical composition of the steel is as follows: Mn is 12.87wt.%, Al is 7.60wt.%, C is 0.72wt.%, P< 0.005%, S<0.002, and the rest are Fe and unavoidable impurities.

[0061] The preparation method of the above-mentioned Fe-Mn-Al-C series cold-rolled automobile steel comprises the following steps:

[0062] Step 1, smelting:

[0063] According to the composition ratio of Fe-Mn-Al-C series cold-rolled automobile steel, it is smelted in a vacuum induction melting furnace and cast to obtain an ingot;

[0064] Step 2, forging:

[0065] (1) Heat the billet to 1200°C and keep it warm for 2 hours;

[0066] (2) forging the ingot billet after heat preservation, air cooling to room temperature to obtain the forged billet, and cutting the billet to obtain a 35mm×120mm square billet;

[0067] Step 3, hot rolling:

[0068] (1) Heat the billet at 1200°C for 2 hours;

[0069] (2) heat-rolling the ingot billet after heat pr...

Embodiment 3

[0078] A Fe-Mn-A1-C series cold-rolled steel for automobiles, the chemical composition of the steel is: C: 0.8%, Mn: 10.0%, Al: 7%, P<0.005%, S<0.002 %, the balance is Fe and unavoidable impurities.

[0079] The preparation method of the above-mentioned Fe-Mn-Al-C series cold-rolled automobile steel comprises the following steps:

[0080] Step 1, smelting:

[0081] According to the composition ratio of Fe-Mn-Al-C series cold-rolled automobile steel, it is smelted in a vacuum induction melting furnace and cast to obtain an ingot;

[0082] Step 2, forging:

[0083] (1) Heat the billet to 1150°C and keep it warm for 3h;

[0084] (2) forging the ingot billet after heat preservation, air cooling to room temperature to obtain the forged billet, and cutting the billet to obtain a 35mm×120mm square billet;

[0085] Step 3, hot rolling:

[0086] (1) Heat the billet at 1160°C for 2.5 hours;

[0087] (2) heat-rolling the ingot billet after heat preservation, carry out rolling 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com