Starter-making method of chicken juice soy sauce, brewing method of chicken juice soy sauce, and soy sauce brewed by brewing method

A technology of soy sauce and chicken sauce, which is applied in the field of koji making method of chicken sauce soy sauce, brewing method of chicken sauce soy sauce and the soy sauce brewed by the brewing method, can solve the problem of increasing the processing cost of sauce dregs, difficulty in guaranteeing the flavor and taste of chicken, and unobtainable Make full use of other problems to achieve the effect of ensuring the activity of koji-making enzyme, delicate texture and pure protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

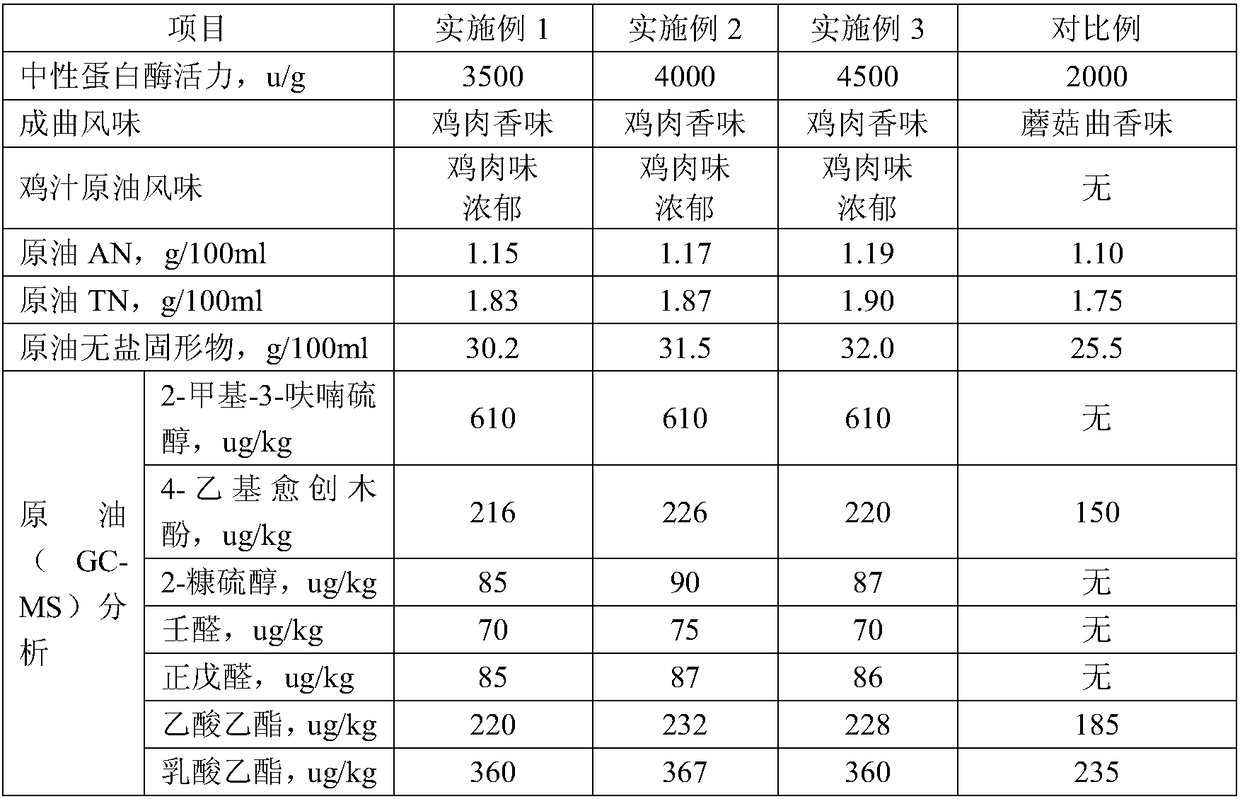

Examples

Embodiment 1

[0034] The chicken juice soy sauce fermentation method provided by the present embodiment comprises the following steps:

[0035] (1) To make soybean powder, put 1 ton of soybeans into a frying pan and fry at 280°C for 5 minutes, and then put it into a pulverizer and grind it into soybean powder for later use;

[0036] (2) To deal with chicken, 1 ton of fresh chicken is washed with 1% brine, cut into pieces of about 0.4cm, then cooked for 8 minutes at a temperature of 125°C and a pressure of 0.15Mpa, and then poured into a rotating frying pan at a temperature of 180°C The frying time is 5 minutes, and 0.3 tons of soybean flour obtained in step (1) is wrapped while hot out of the pan to obtain 1.3 tons of spare chicken;

[0037] (3) To make chicken tofu, soak 1 ton of soybeans in 2 tons of water for 5 hours, then grind the soaked soybeans into soy milk, where the dregs and pulp are not separated, put the soybean milk with dregs into a cooking pot, and boil at 95°C to maintain ...

Embodiment 2

[0045] The chicken juice soy sauce fermentation method provided by the present embodiment comprises the following steps:

[0046] (1) To make soybean powder, put 1 ton of soybeans into a frying pan and fry at 290°C for 4 minutes, and then put it into a pulverizer and grind it into soybean powder for later use;

[0047] (2) To treat chicken, 1 ton of fresh chicken was washed with 2% brine, cut into 0.5cm pieces, then steamed at 128°C and 0.17Mpa for 7 minutes, and then poured into a rotating frying pan and fry at 185°C for 4 minutes , wrap in 0.4 tons of soybean flour obtained in step (1) while it is hot, and obtain 1.4 tons of spare chicken;

[0048] (3) To make chicken tofu, soak 1 ton of soybeans in 2.5 tons of water for 7 hours, then grind the soaked soybeans into soy milk, where the dregs and pulp are not separated, put the soybean milk with dregs in a cooking pot, boil at 98°C for 4 minutes , add 0.8% edible gypsum according to the quality of soybean before soaking, and ...

Embodiment 3

[0056] The chicken juice soy sauce fermentation method provided by the present embodiment comprises the following steps:

[0057] (1) To make soybean powder, put 1 ton of soybeans into a frying pan and fry at 300° C. for 3 minutes, and then put it into a pulverizer and grind it into soybean powder for later use;

[0058] (2) To treat chicken, 1 ton of fresh chicken was washed with 3% brine, cut into 0.6cm pieces, then steamed at 130°C and 0.2Mpa for 6 minutes, and then poured into a rotating frying pan and fry at 190°C for 3 minutes , wrap 0.5 tons of soybean flour obtained in step (1) while it is hot out of the pan, and obtain 1.5 tons of spare chicken;

[0059] (3) To make chicken tofu, soak 1 ton of soybeans in 3 tons of water for 8 hours, then grind the soaked soybeans into soy milk, where the dregs and pulp are not separated, put the soy milk with dregs into a cooking pot, boil at 100°C for 3 minutes , add 1.0% edible gypsum according to the mass of soybeans before soaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com