Lodoicea maldivica flesh piece drying and processing equipment

A technology for processing equipment and meat slices, applied in the field of drying and processing equipment for seabed coconut pulp slices, can solve the problems of not drying the pulp well, dehydrating the pulp too much, and being difficult to collect, etc., so as to improve the dehydration efficiency and quality, improve the uniformity, and facilitate recovery. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

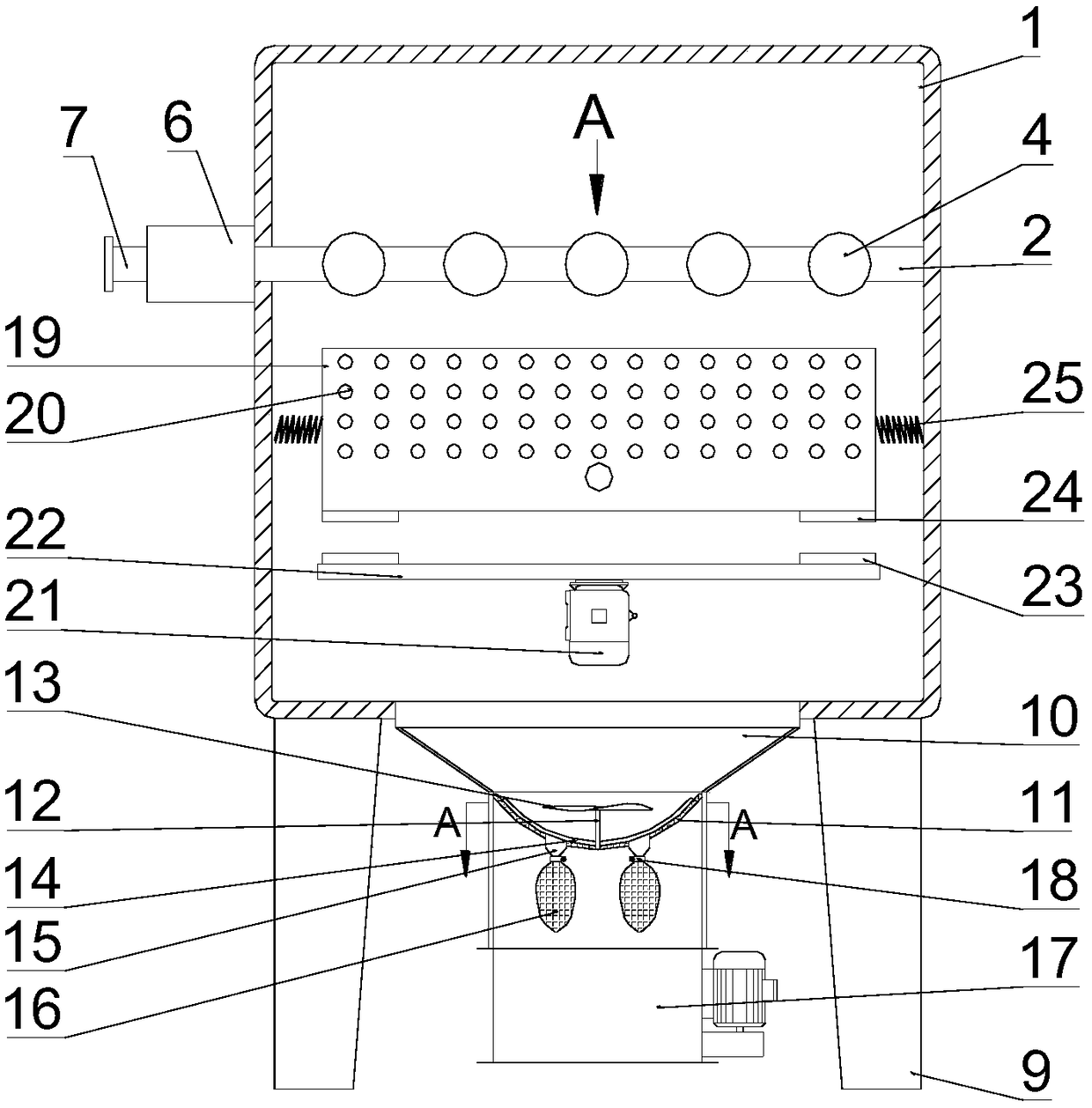

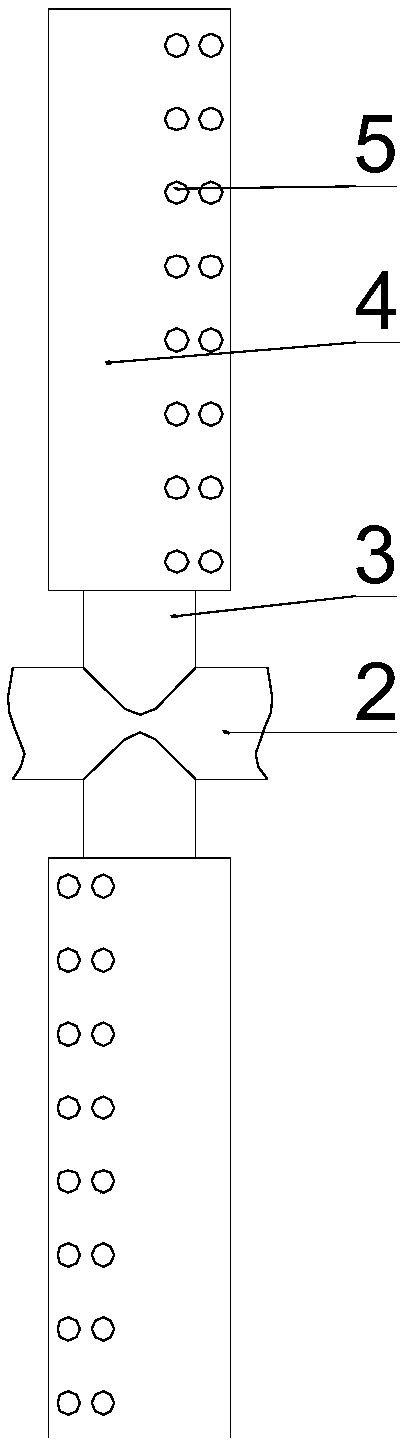

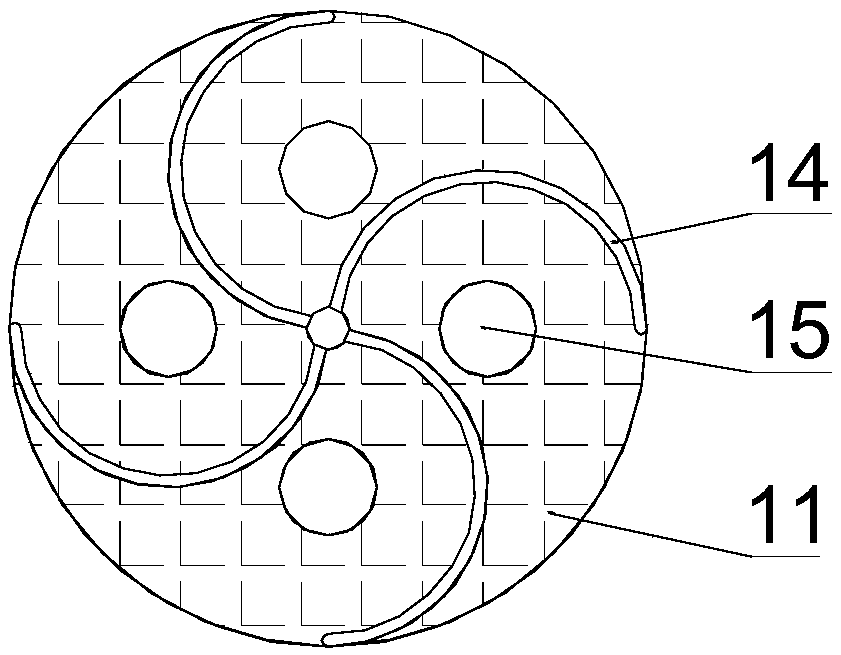

[0022] See Figure 1-2 , A sea coconut pulp piece drying processing equipment, comprising a drying box 1, the inside of the drying box 1 is fixedly connected with a fixed pipe 2, the surface of the drying box 1 is installed with a duct type gas heater 6, the fixed pipe 2 and the wind The duct type gas heater 6 is connected, the duct type gas heater 6 is provided with a connecting pipe 7, and the fixed pipe 2 is fixed with a number of branch pipes 3 connected to the pipe, and the branch pipe 3 is rotatably connected with a rotating pipe 4. The surface of the rotating tube 4 is provided with several groups of air injection holes 5. The space line formed by the air injection direction of the air injection holes 5 is tangent to the circumferential surface of the rotating tube 4, and the lower part of the rotating tube 4 is provided with an upper opening s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com