Manufacturing technology of screw

A production process and screw technology, applied in the field of screw production technology, can solve the problems of complicated steps, manual cleaning, and complicated production, and achieve the effects of convenient production, reduced artificial strength and good driving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

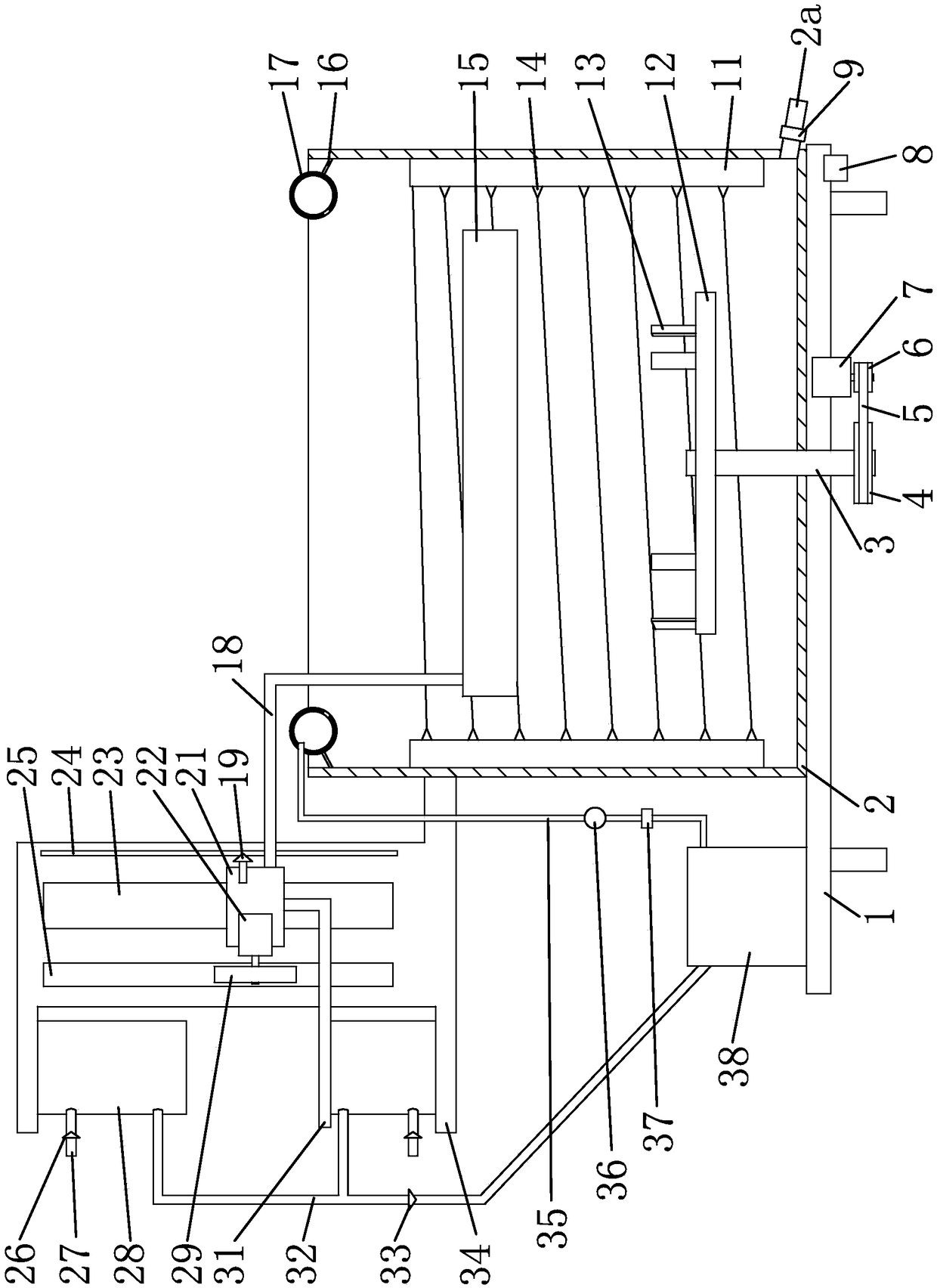

[0035] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0036] The manufacturing process of the screw includes the following steps:

[0037] a. Cutting: buy steel wire, cut the steel wire according to the given specification and length, and obtain the steel wire segment;

[0038] B, heading: heading one end of the wire segment by the heading device, and processing the shape of the screw head; in the present embodiment, the heading device adopts the existing equipment;

[0039] c. Clamping the tail: the other end of the wire segment is punched by the punching device to process the shape of the nail tip; in this embodiment, the punching device adopts the existing equipment;

[0040] d. Thread rolling: thread rolling is performed around the steel wire segment through a thread rolling device to process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com