Oil-gas dual-purpose cylinder and control system thereof

A control system and dual-purpose technology, applied in the hydraulic field, can solve the problem of too fast opening and closing of the drive cylinder in the initial stage, and achieve good practicability and interoperability, good driving effect, and more stable driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

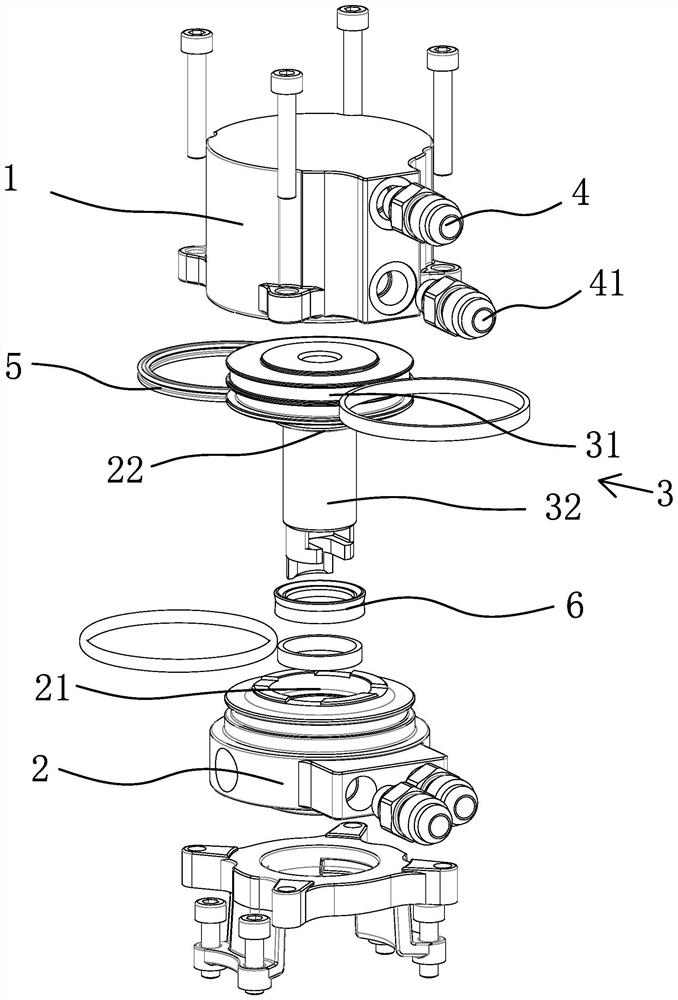

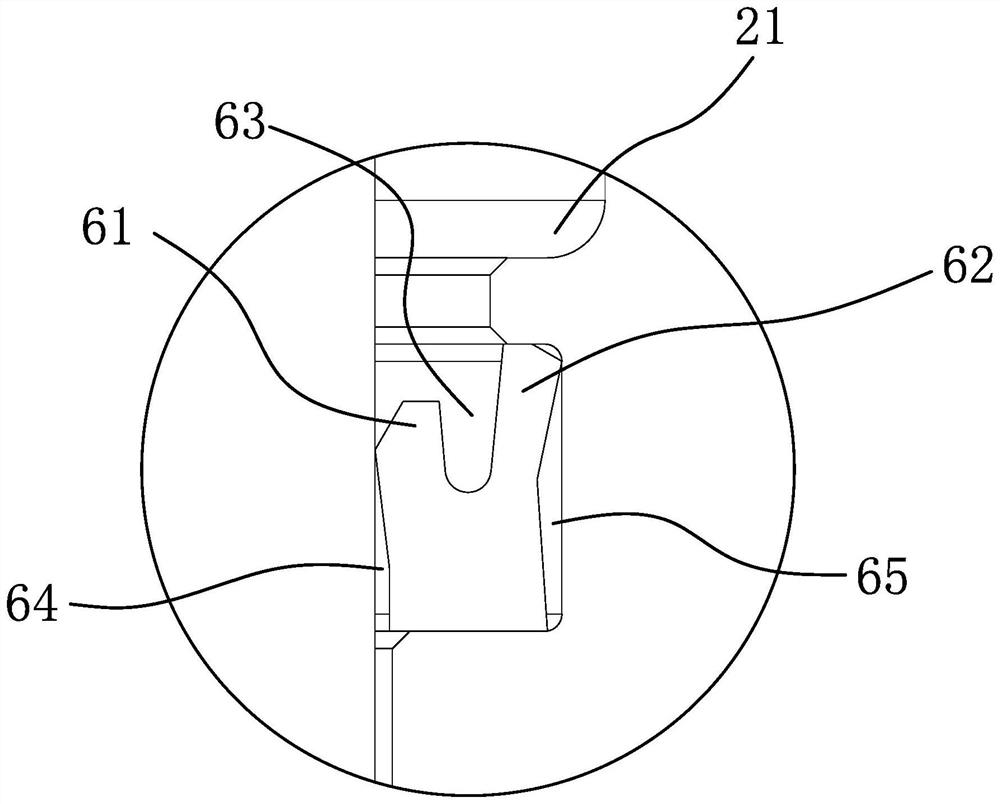

[0031] Specific embodiment 1 such as Figure 1-3 Shown: an oil-gas dual-purpose cylinder, including a cylinder body 1 and a cylinder head 2, a sealed cavity is formed between the cylinder body 1 and the cylinder head 2, and a piston 3 is arranged inside the cylinder body 1, so The cylinder body 1 is provided with a medium inlet 4 and a medium outlet 41 communicating with the cavity, the piston 3 includes a piston head 31 and a piston column 32, and the piston head 31 and the inner wall of the cylinder body 1 are provided with The first sealing ring 5, the self-sealing ring 6 that can change the contact stress between itself and the piston rod 32 with the change of medium pressure is arranged between the piston rod 32 and the cylinder head 2. The medium includes liquid medium and gas medium, that is, the oil-air dual-purpose cylinder can be used as an air cylinder or a hydraulic cylinder; in the scene where the oil-air dual-purpose cylinder is an air cylinder, the pressure of t...

specific Embodiment 2

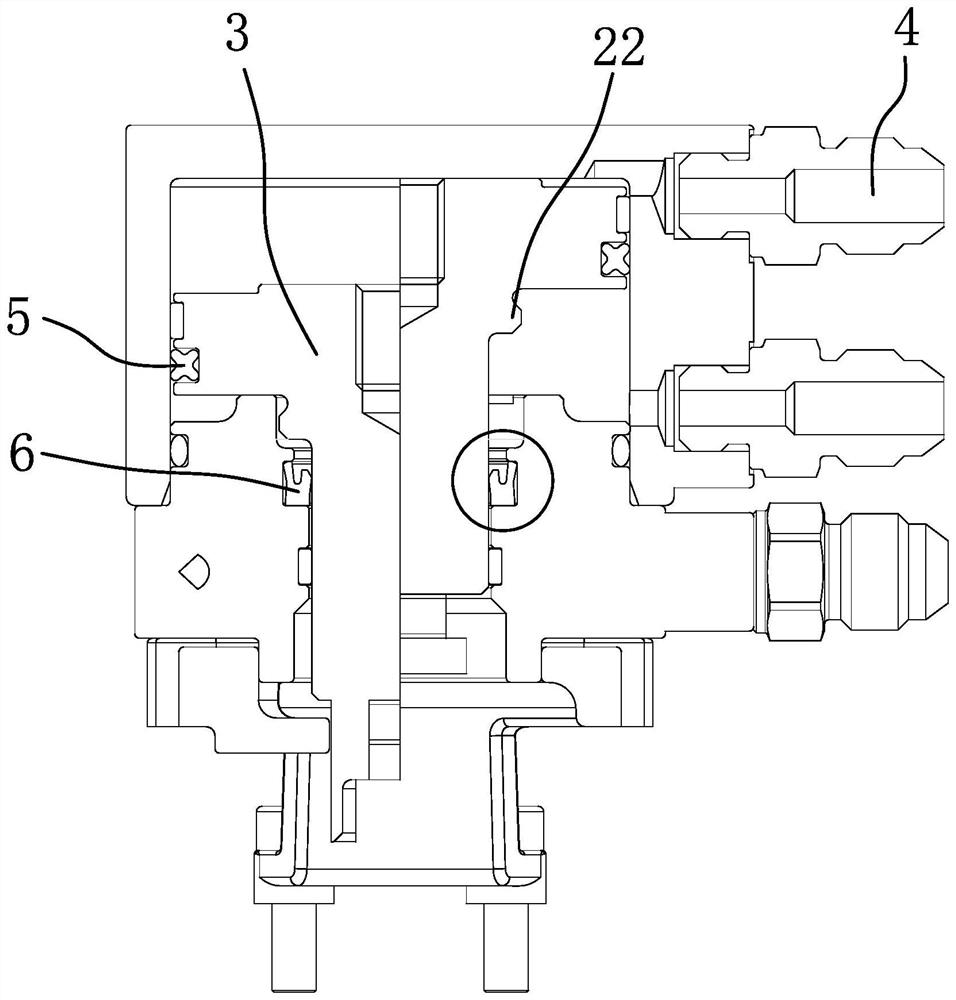

[0035] Specific embodiment 2 such as Figure 4-7 Shown: a control system of an oil-air dual-purpose cylinder, which is used to control when the medium in the oil-air dual-purpose cylinder is liquid. The control system includes an oil tank, a power pump, and a two-position four-way reversing valve connected in sequence 7, and the throttle valve 71 and the two-position two-way valve 72 connected in parallel are finally connected to the hydraulic cylinder whose medium is liquid, and the throttle valve 71 and the two-position two-way valve 72 are used to control the oil and gas cylinder speed, when the two-position two-way valve 72 is opened, the hydraulic cylinder is in the first flow state; when the two-position two-way valve 72 is closed, the hydraulic cylinder is in the second flow state when the medium only passes through the throttle valve 71, and the first The flow rate is greater than the second flow rate; when the piston rod 32 is in the extended state to be retracted, th...

Embodiment 2

[0037] The working process of embodiment 2 is as follows: as Figure 4 After the valve needle 9 completes a round of injection molding work, the power pump in the control system inputs pressure oil into the rodless chamber of the hydraulic cylinder through the two-position four-way reversing valve 7, and the pressure oil in the rod chamber is transferred from the one-way speed regulating valve The check valve flows back to the oil tank, and now the valve needle 9 on the piston rod 32 enters a closed state.

[0038] Such as Figure 5 , when the next injection is about to start, the two-position four-way reversing valve 7 is energized to complete the switching between P and T ports, so that the pressure oil flows to the rod chamber. During this process, the one-way The throttle valve 71 restricts the pressure oil flow into the rod cavity according to the set throttle opening size, so as to control the opening speed of the valve needle 9, while the two-position two-way valve 72 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com