Flexible airbag grinding and polishing tool with multiple motion freedom degrees

A technology with a degree of freedom and multi-motion, applied in the direction of grinding tools, manufacturing tools, metal processing equipment, etc., can solve problems such as large structure, poor flexibility, and poor connection of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

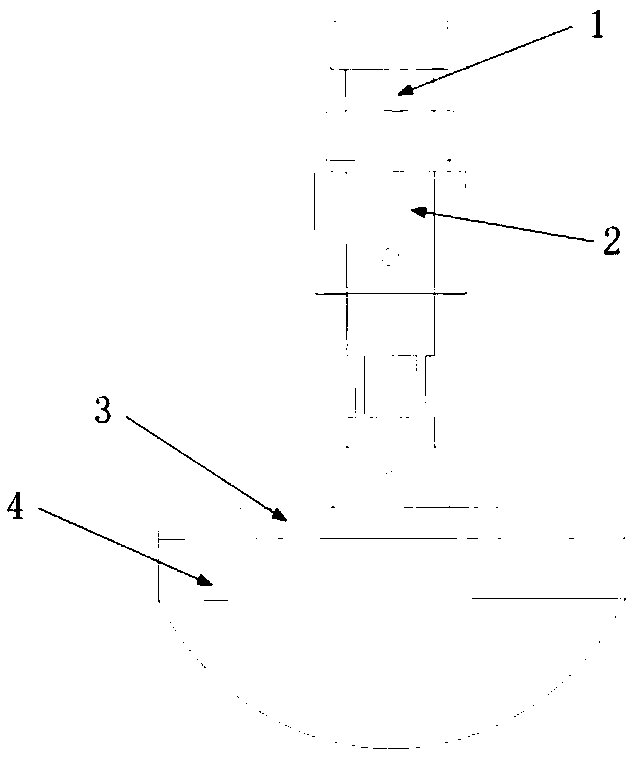

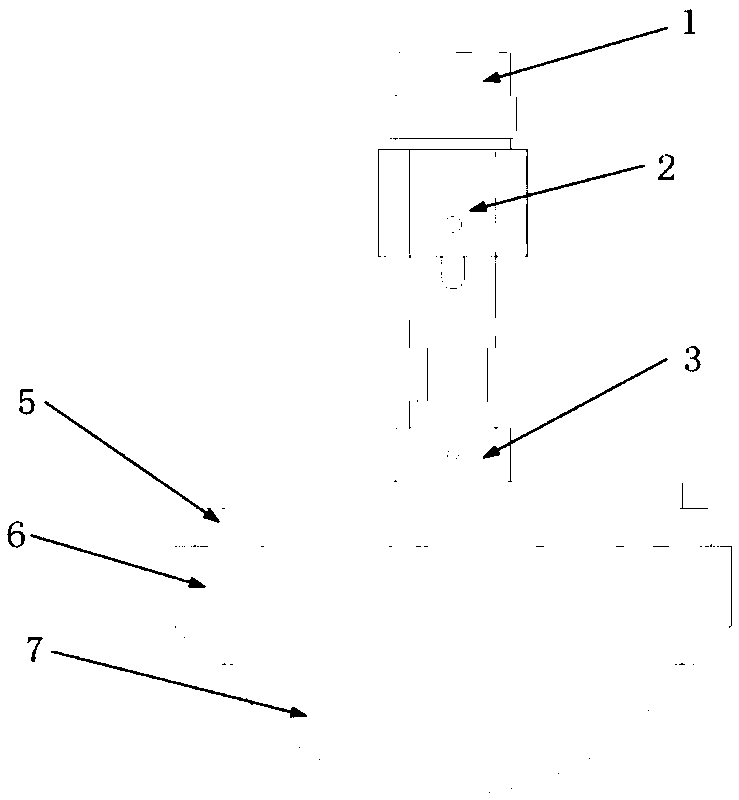

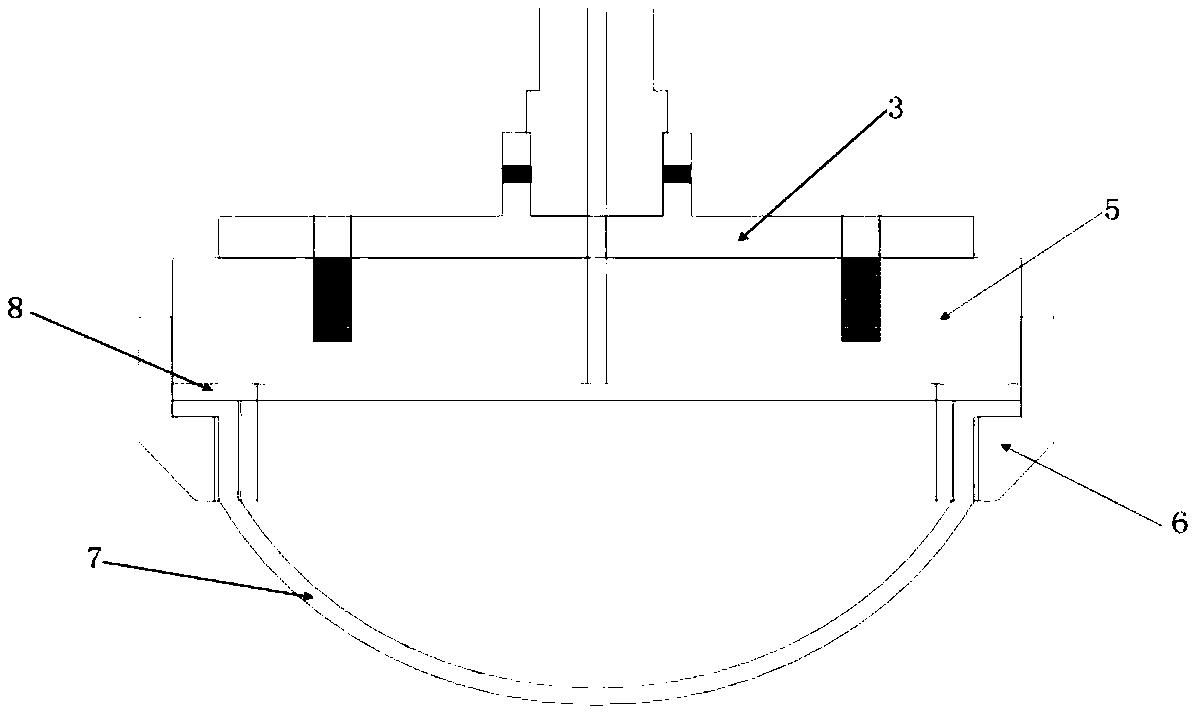

[0019] First, the base is fixed (27), and the rotary servo motor (28) drives the column (26) to perform a degree of freedom movement around the column. The big arm servo motor (25) drives the big arm electric cylinder (24) to carry out telescopic movement, and the small arm servo motor (22) drives the small arm electric cylinder (21) to carry out telescopic movement, thereby drives the big arm (23), the small arm (20 ) movement to realize the two degrees of freedom movement of the manipulator in the horizontal and vertical directions. The oscillating servo motor (19) drives the pendulum shaft (17) to perform a oscillating movement with one degree of freedom through the worm and worm structure in the wrist box (18), which can meet the precession angle requirements during workpiece processing, and then configure the AC servo motor to pass The belt drives the pulley (16) for transmission. In the grinding stage, replace the grinding tool hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com