A plugging and pressing material for air leakage of the bottom foundation of the hot blast stove

A technology of pressing material and hot blast stove, applied in the field of refractory materials, can solve the problems of large amount of liquid added, not meeting the requirements for use, and easy to crack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

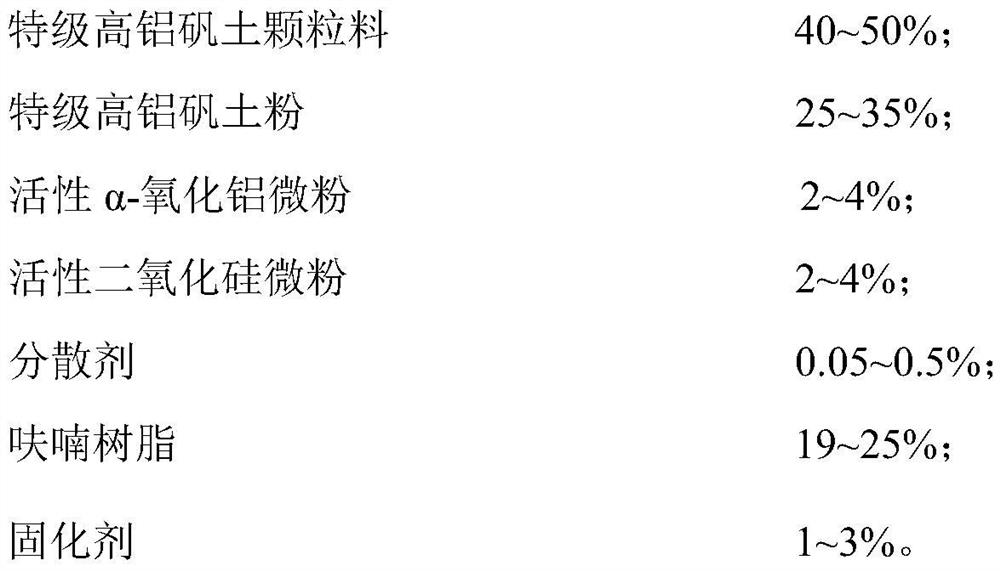

[0033] A plugging press-feed material used for air leakage at the bottom of a hot blast stove. The components and their mass percentages are: 48% of super-grade high-bauxite particles, 25% of super-grade high-bauxite powder, and active silica 2% of micropowder, 3% of active α-alumina micropowder, 0.2% of dispersant, 20% of furan resin, 1.8% of curing agent; its preparation method comprises the following steps: weighing super-grade high-alumina bauxite granules, super-grade high-alumina Bauxite powder, active silica micropowder, active aluminum oxide, and dispersant are weighed according to the proportion and added to a forced mixer to mix evenly. The resulting mixture is packed and transported in tons of bags; When used on site, put the mixture into a forced mixer, add furan resin and curing agent according to the proportion and stir for 5-8 minutes, and directly use the cement mortar pump to press into the leaking part to be sealed.

Embodiment 2

[0035] A plugging press-feed material used for air leakage at the bottom of a hot blast furnace, the components and their mass percentages are: 42% of super-grade high-bauxite particles, 25% of super-grade high-bauxite powder, active silica 2% micropowder, 3% active α-alumina micropowder, 0.2% dispersant, 25% furan resin, and 2.8% curing agent; Bauxite powder, active silica micropowder, active aluminum oxide, and dispersant are weighed according to the proportion and added to a forced mixer to mix evenly. The resulting mixture is packed and transported in tons of bags; When used on site, put the mixture into a forced mixer, add furan resin and curing agent according to the proportion and stir for 5-8 minutes, and directly use the cement mortar pump to press into the leaking part to be sealed.

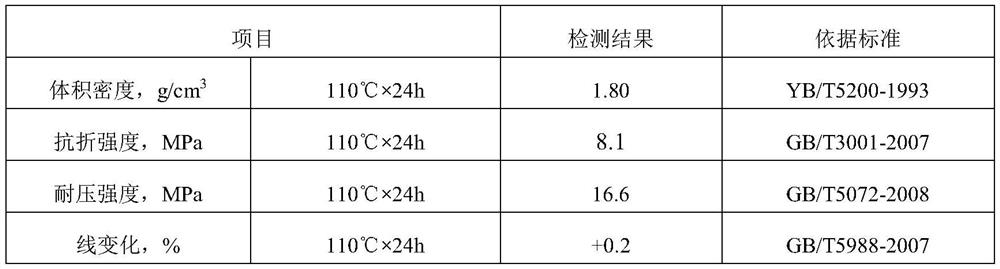

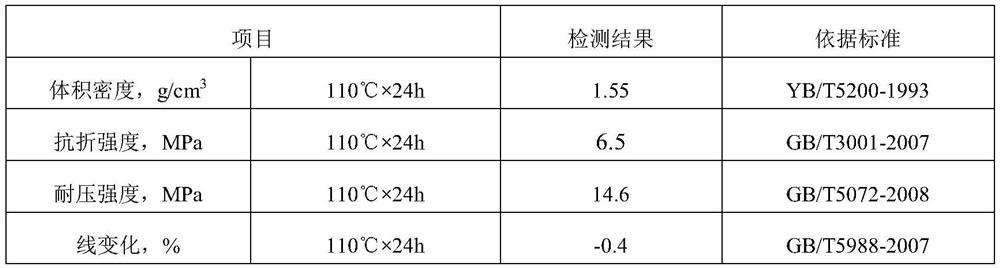

[0036] The performance test results of the plugging material obtained in Example 1 of the present invention are shown in Table 1, and the performance test results of Example 2 are equiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com