Preparation method of high-viscosity poly(butylene succinate)/polylactic acid composite material

A technology of polybutylene succinate and composite materials, which is applied in the field of preparation of high-viscosity polybutylene succinate/polylactic acid composite materials, and can solve the problem of rare viscosity increase and modification of PBS/PLA composite materials problems, to achieve the effect of good mechanical properties, high viscosity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16 and comparative example 1-3

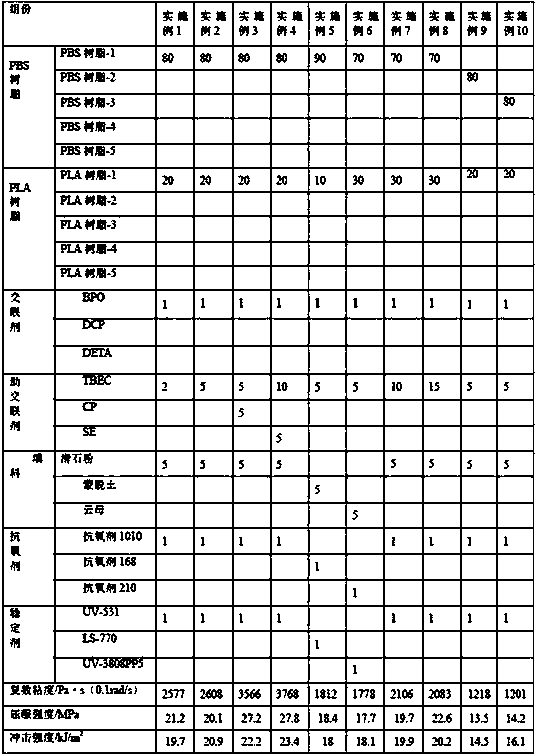

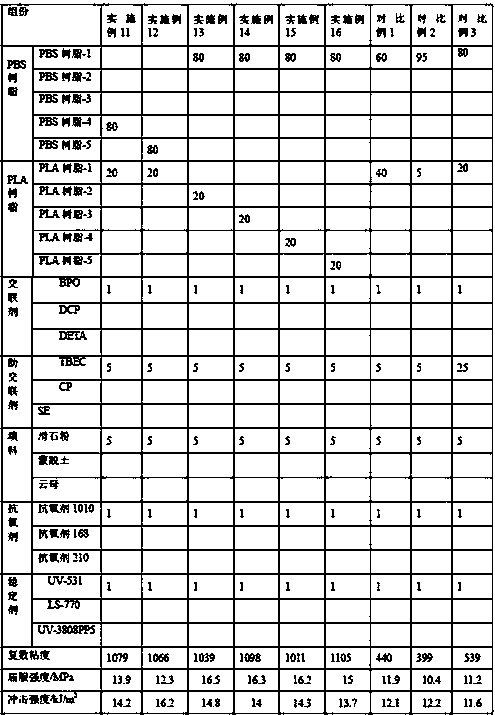

[0070] Examples 1-16 and Comparative Examples 1-3: Preparation of high-viscosity polybutylene succinate / polylactic acid composite material

[0071] Mix PBS resin, PLA resin, crosslinking agent, co-crosslinking agent, filler, antioxidant, and stabilizer according to the ratio in Table 1 in a high-speed mixer (the mechanical mixing speed is 50-500r / min, and the mixing time is 0.5-15min) ) for mechanical mixing to obtain a premix; put the obtained premix into a twin-screw extruder (rotating speed 20-400r / min, barrel temperature 150-210°C) for melting and reactive extrusion to obtain high Viscosity polybutylene succinate / polylactic acid composite material; the prepared high-viscosity polybutylene succinate / polylactic acid composite material is tested for complex viscosity, yield strength and impact strength, and the test results are shown in Table 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com