Energy saving and rapid ion nitriding technology for alloy steel worm

An ion nitriding and alloy steel technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low efficiency, long time, high power consumption, etc. The effect of saving ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

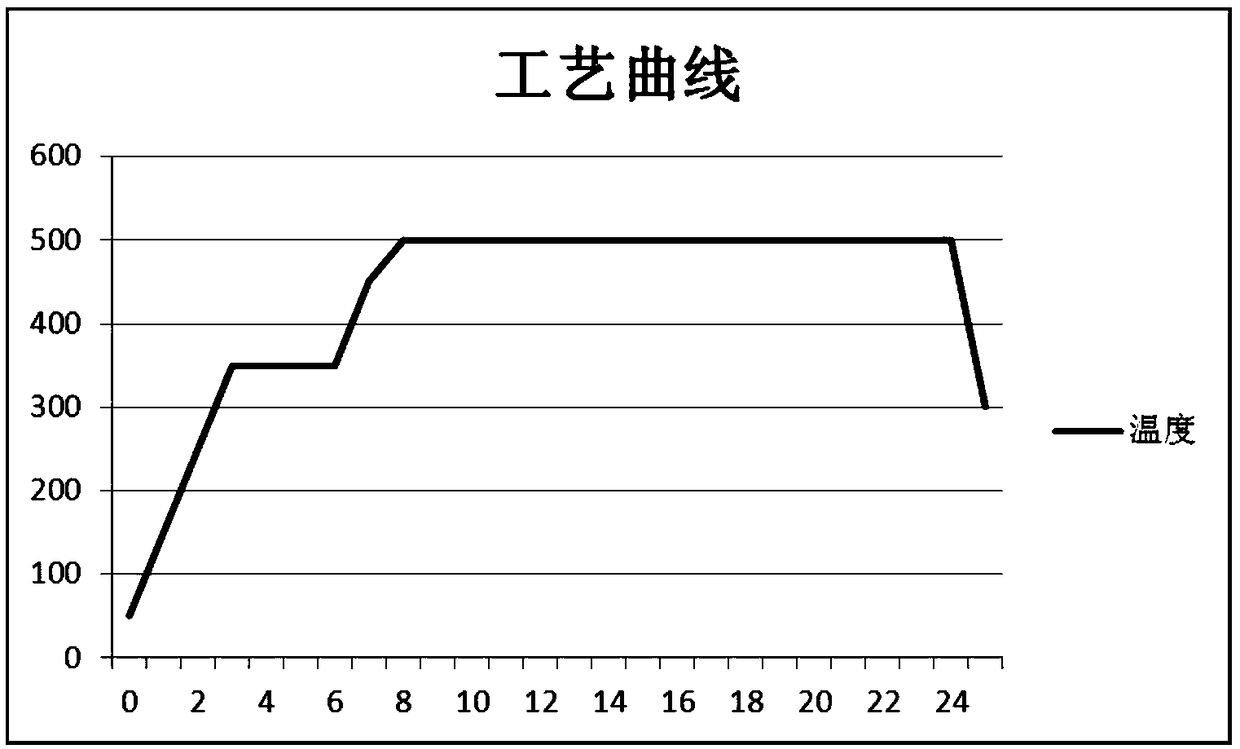

[0020] The energy-saving and fast ion nitriding process of alloy steel worm includes the following steps:

[0021] Step 1: Clean the alloy steel worm workpiece with an ultrasonic cleaning machine to remove the oil stain on the surface of the alloy steel worm workpiece; put the alloy steel worm workpiece into the nitriding furnace;

[0022] The second step: use the alloy steel worm workpiece as the cathode, and the furnace wall as the anode, and vacuumize the nitriding furnace to below 150Pa;

[0023] Step 3: Connect the bipolar direct current of the nitriding furnace, and under the conditions of 150Pa and voltage 500-600V, arc the alloy steel worm workpiece by plasma bombardment; , oxides are removed, and thus purified;

[0024] Step 4: After arcing, gradually increase the current between the two poles (according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com