Pear syrup candy processing system

A processing system, the technology of pear paste candy, which is applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of low cooling efficiency, poor practicability, and candy bars are easily broken, so as to prevent personnel injuries and improve cooling efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, and the direction words such as front, back, left, right, etc. adopted in the present invention are all based on the flow direction of cooling water.

[0036] A pear paste sugar processing system of the present invention includes a cooling device and a candy block forming device, and its devices for squeezing juice, boiling, and packaging can adopt structures in the prior art, wherein,

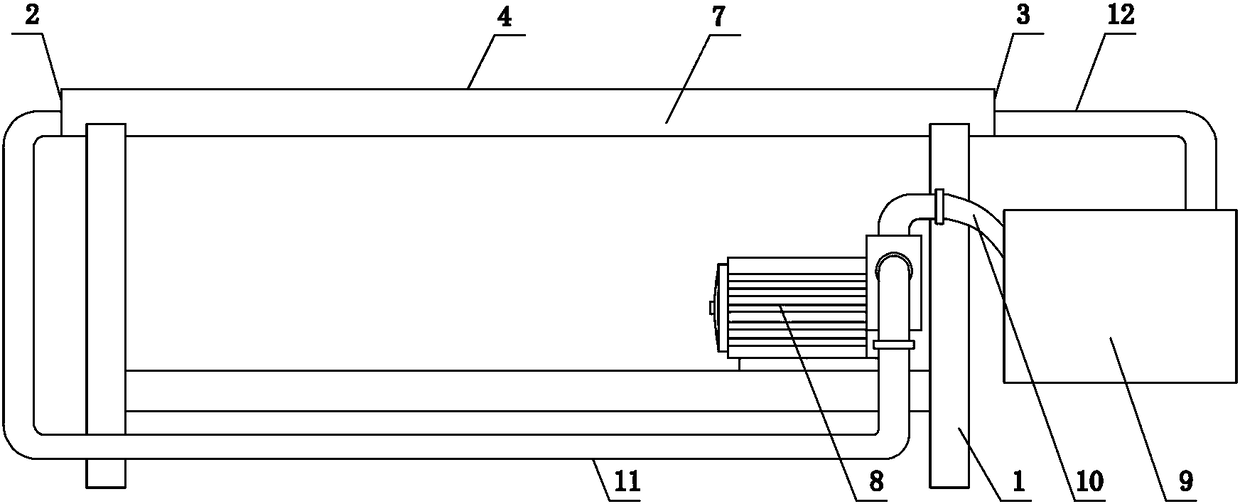

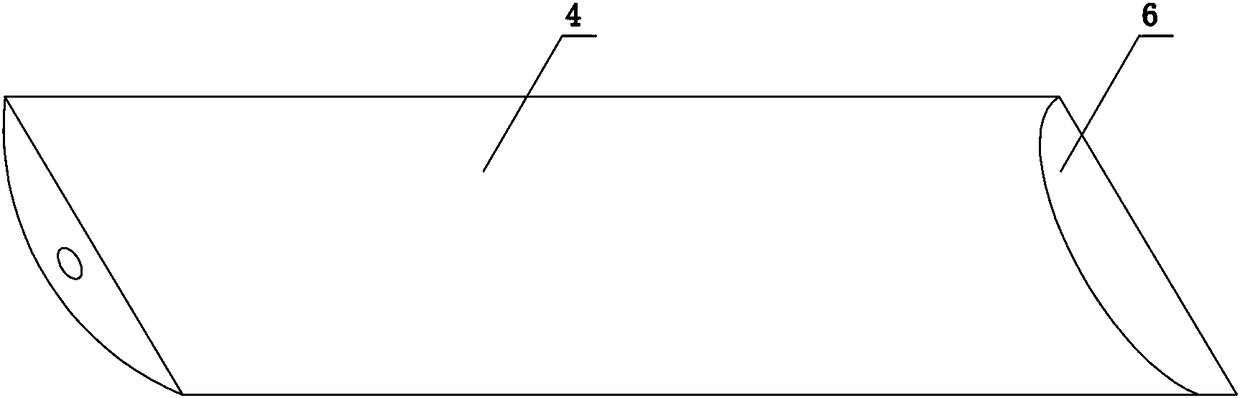

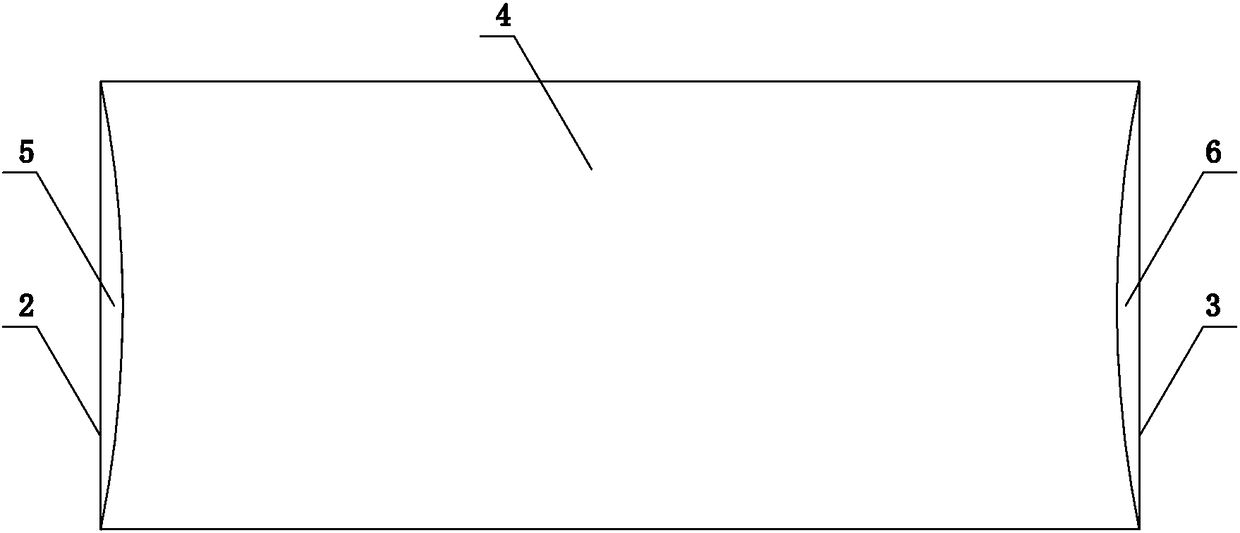

[0037] like Figure 1 to Figure 3 As shown, the cooling device includes a cooling box, a first support frame 1 and a water circulation mechanism. Both the cooling box and the water circulation mechanism are fixedly installed on the first support frame 1 by bolts. The cooling box is a sealed structure, including a front baffle plate 2, a rear The baffle plate 3, the top plate 4, the front inclined plate 5, the rear inclined plate 6 and the bottom plate 7, the top plate 4 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com