Steel pipe pile cofferdam for bridge deepwater foundation and construction method thereof

A deep-water foundation and steel pipe pile technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems such as the inability to meet the construction requirements of the strength and the closed water of the teeth, the inability to guarantee the depth and overall rigidity of the soil, and the inconvenient use of tall machinery. Achieve the effect of improving convenience, splicing convenience, and improving connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

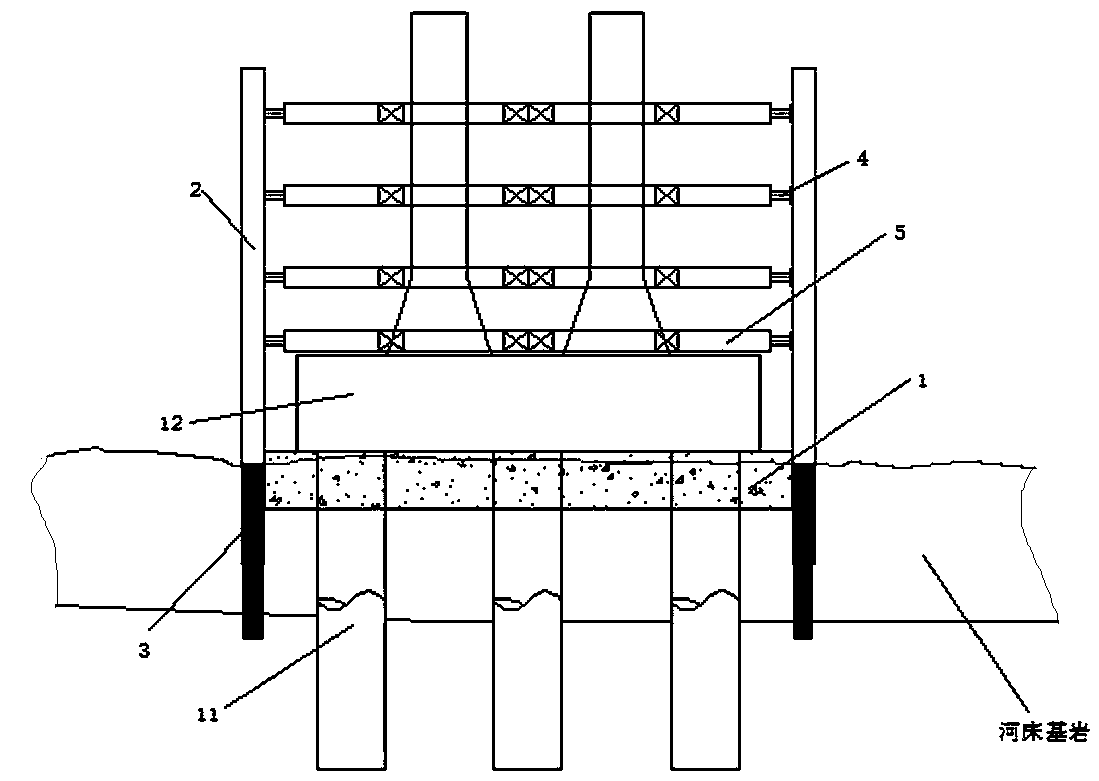

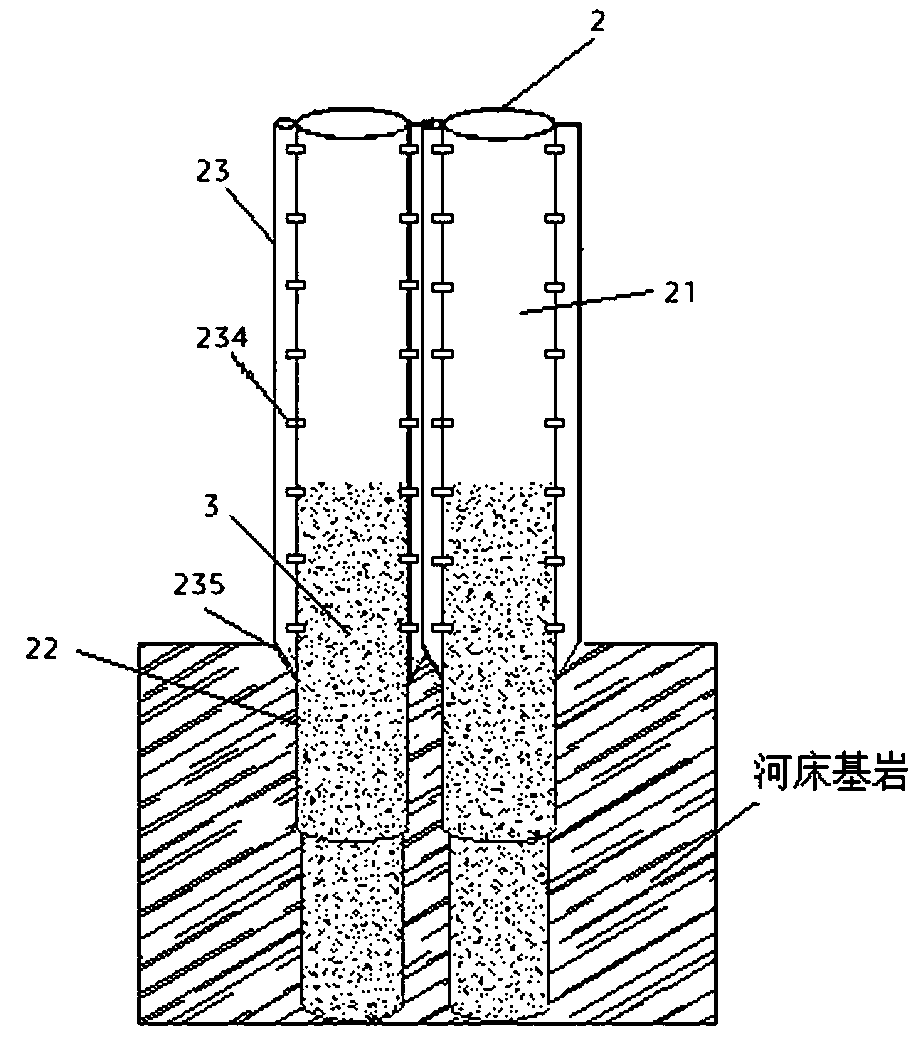

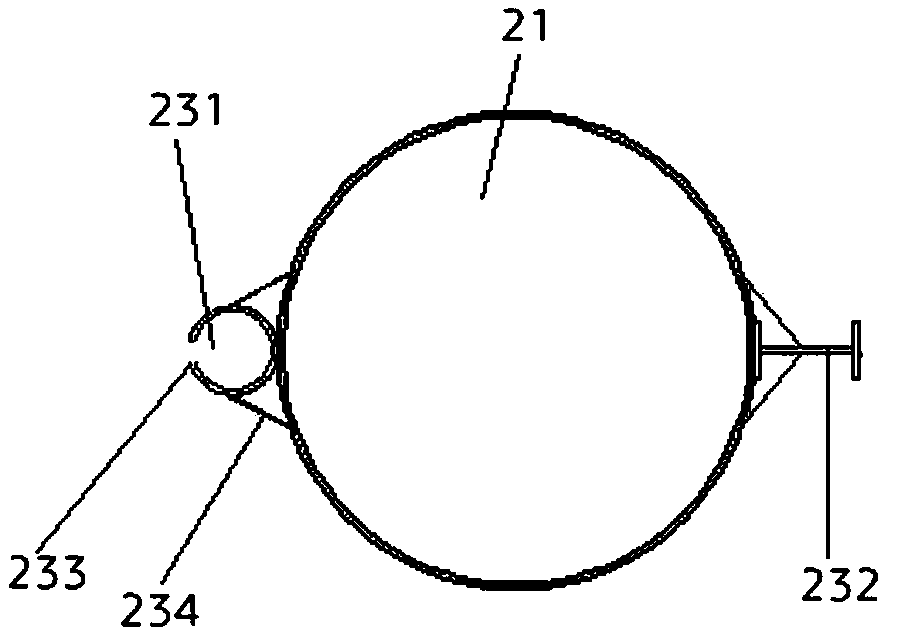

[0040] like figure 1 , 2 A cofferdam of steel pipe piles for deep water foundations of bridges is shown, including back-sealing concrete 1, locking steel pipe piles 2, and reinforced concrete piles 3. The back-sealing concrete 1 is located on the top of the bedrock at the bottom of the river bed and partially extends downward On the surface of the bedrock, the back-sealing concrete 1 is in the shape of a cuboid. A pile foundation 11 that goes deep into the bedrock is arranged below the back-sealing concrete 1 . The locking steel pipe pile 2 includes a pile body 21 and a lock 23 arranged on the wall surface of the pile body 21. A plurality of locking steel pipe piles 2 are surrounded by the edge of the bottom concrete 1 through the head-to-tail connection of the lock 23. The lower end of the pile body 21 is connected to the The free surface of the bedrock surface is in contact and the lower end of the pile body 21 is integrally formed and has a pile head 22 extending downward...

Embodiment 2

[0047] The technical solution described in this embodiment is similar to Embodiment 1, the difference is that:

[0048] In this embodiment, the pile head 22 has a length of 2 meters.

[0049] In this embodiment, the end of the pile head 22 is provided with an expansion interface. The extension interface is an annular bevel formed around the end of the pile head 22. If there is a need to extend the depth of the pile foundation, the extension section can be welded on the extension interface by means of symmetrical subsidized groove welding.

Embodiment 3

[0051] This embodiment provides a construction method for the cofferdam described in Embodiment 1, which includes the following steps:

[0052] Step S1: Construction locking steel pipe pile 2, choose 820mm steel pipe as pile body 21 and pile head 22, lock 23 choose 159mm seamless steel pipe as female lock 231, use I18 I-shaped steel as male lock 232, weld Integral locking steel pipe pile 2;

[0053] Step S2: sinking the pile by vibration for the first time, passing the locking steel pipe pile 2 through the DJZ120 vibrating hammer to vibrate the pile until the end of the locking steel pipe pile 2 sinks into the bedrock surface;

[0054] Step S3: For the first pilot hole, use the auger bit and slag removal bit of the XD220 rotary excavator to drill 1.5 meters into the bedrock in the locking steel pipe pile 2 and form a free surface;

[0055] Step S4: The second vibration pile sinking, the locked steel pipe pile 2 continues to vibrate downward along the hole formed in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com