Minitype compressor with built-in liquid reservoir

A technology for a compressor and a liquid accumulator, applied in the field of compressors, can solve the problems of inconvenient disassembly and assembly, maintenance of the whole machine, small space position, poor welding, etc., and achieves the advantages of small space installation, compact internal structure, and reduced installation procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

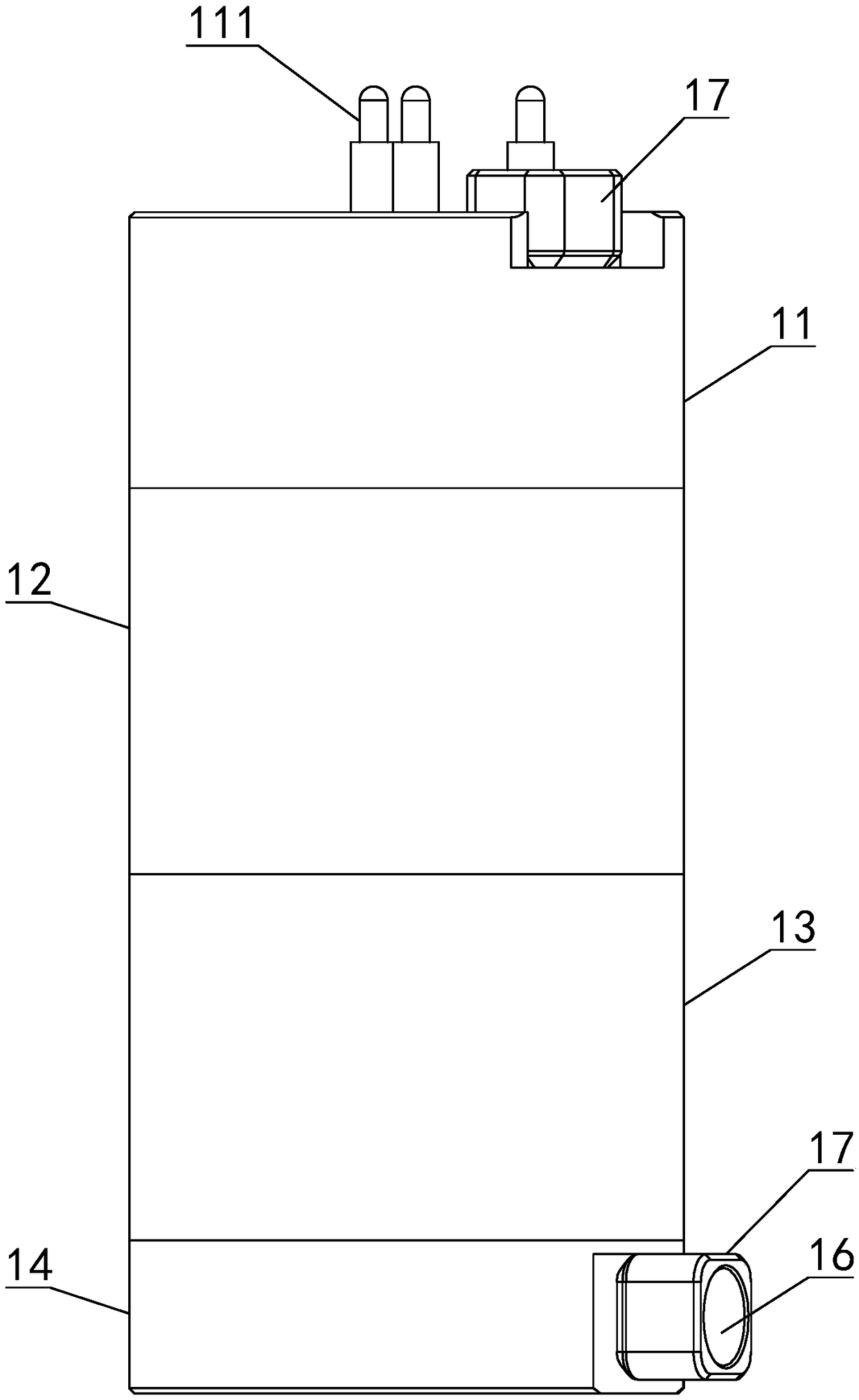

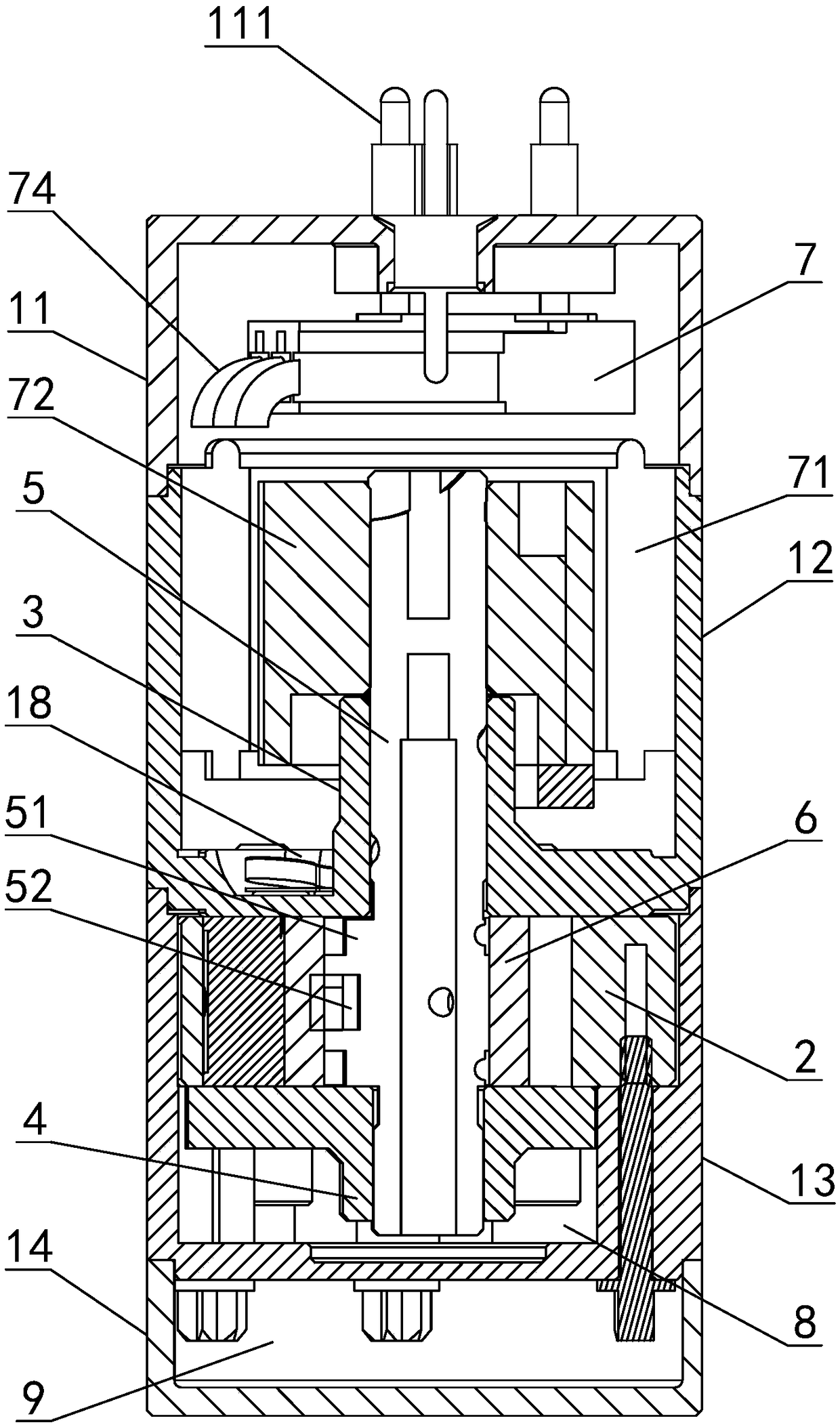

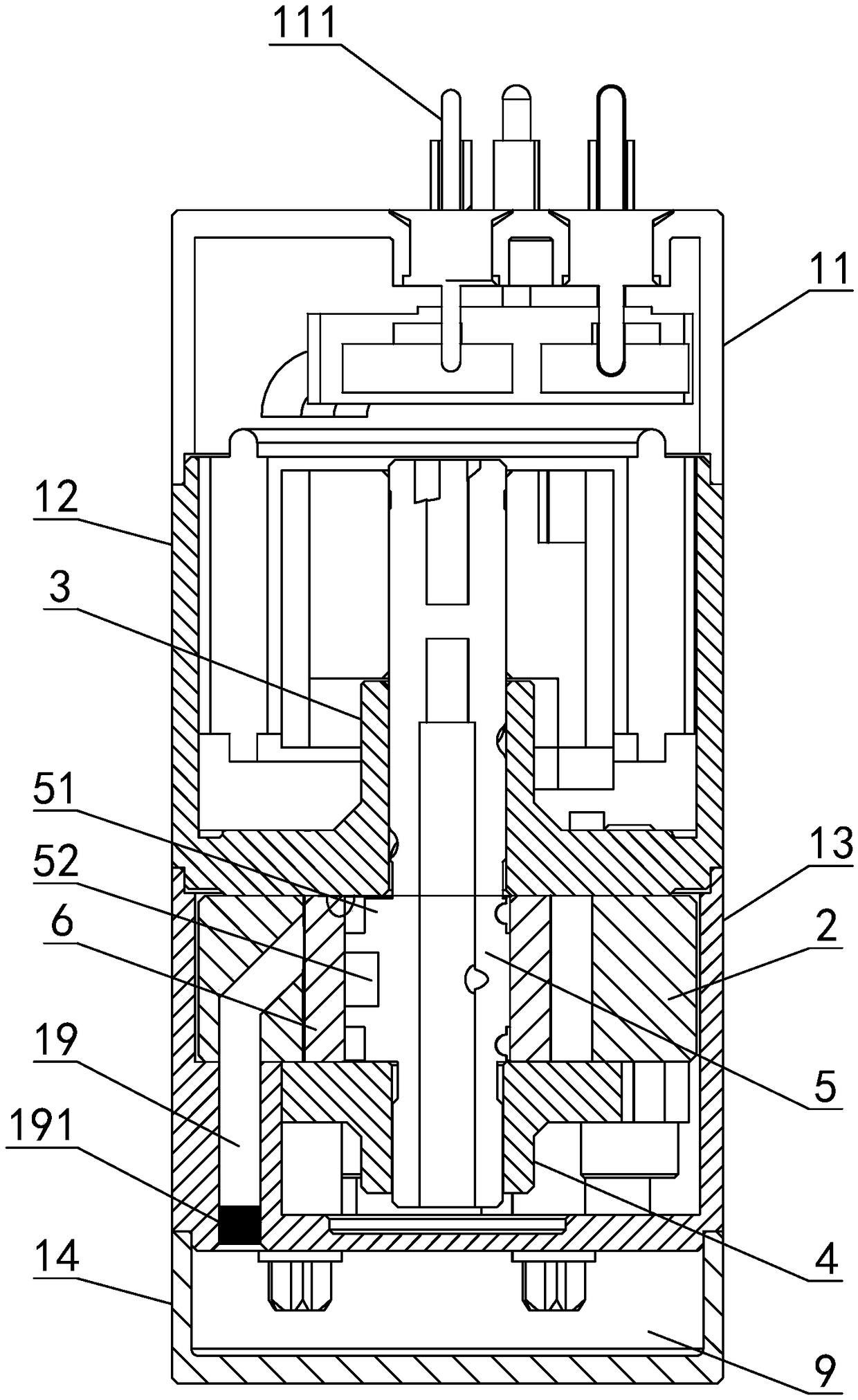

[0021] refer to Figure 1 to Figure 6 , the present invention is a micro-compressor with a built-in liquid accumulator, including a compressor main body, a cylinder 2, a main bearing 3, an auxiliary bearing 4, a crankshaft 5, a piston 6 and a motor 7 are installed in the compressor main body, and the compressor main body includes The high-pressure end cover 11, the main body frame 12, the compression chamber shell 13, and the low-pressure end cover 14 are sequentially matched and connected from top to bottom. A low-pressure refrigerant inlet 16, a high-pressure refrigerant outlet 15 and a low-pressure refrigerant inlet 16 are connected with flared copper tubes, and quick-connect nuts 17 are pre-installed on the copper tubes. The oil sump 8 is to store lubricating oil in all compressors, and the cavity formed by the low pressure end cover 14 and the compression chamber shell 13 is the liquid accumulator 9. Wherein, the cylinder 2, the main bearing 3, the auxiliary bearing 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com