TFT array substrate and liquid crystal display panel

An array substrate and display area technology, applied in optics, instruments, electrical and digital data processing, etc., can solve the problems of inability to fan out the size of the trace area, such as compression, inability to overlap, etc., to achieve reduced area, small size, and narrow borders. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

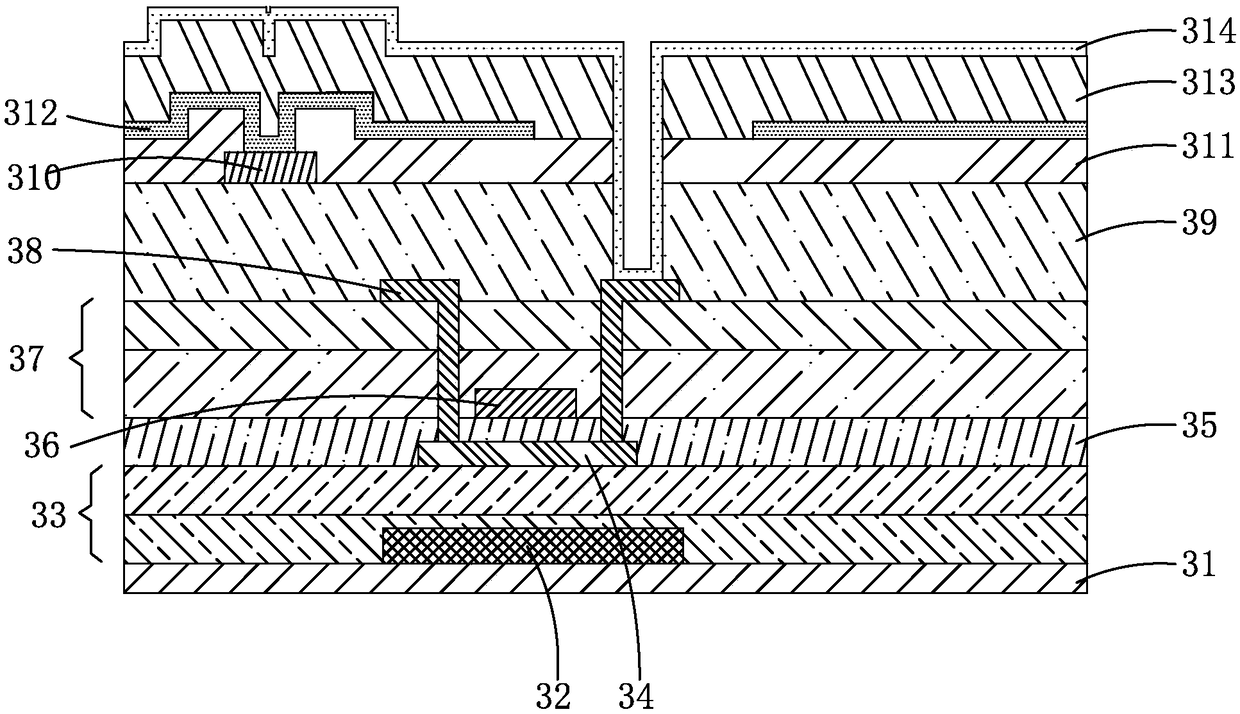

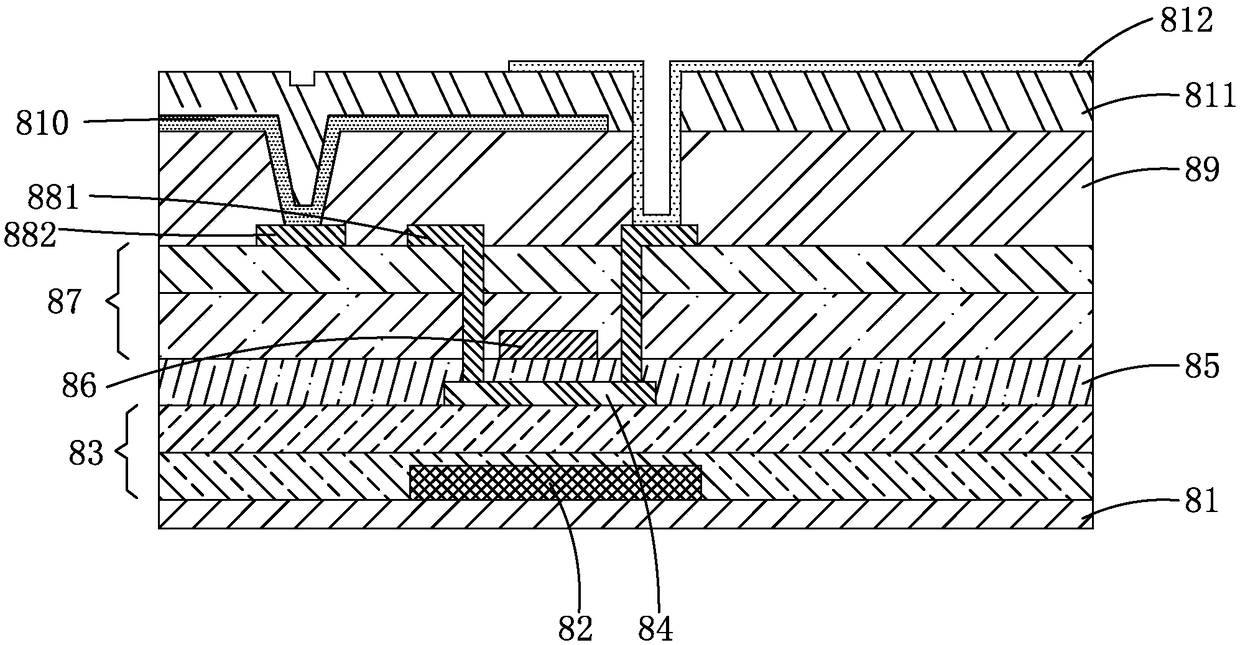

[0061] see Figure 5 and Figure 6 , The first embodiment of the TFT array substrate of the present invention includes a substrate 100, a first metal layer 200 disposed above the substrate 100, a first interlayer insulating layer 300 covering the first metal layer 200, and a first interlayer insulating layer 300 disposed on the first layer The second metal layer 400 on the interlayer insulating layer 300 , the second interlayer insulating layer 500 covering the second metal layer 400 , and the third metal layer 600 disposed on the second interlayer insulating layer 500 .

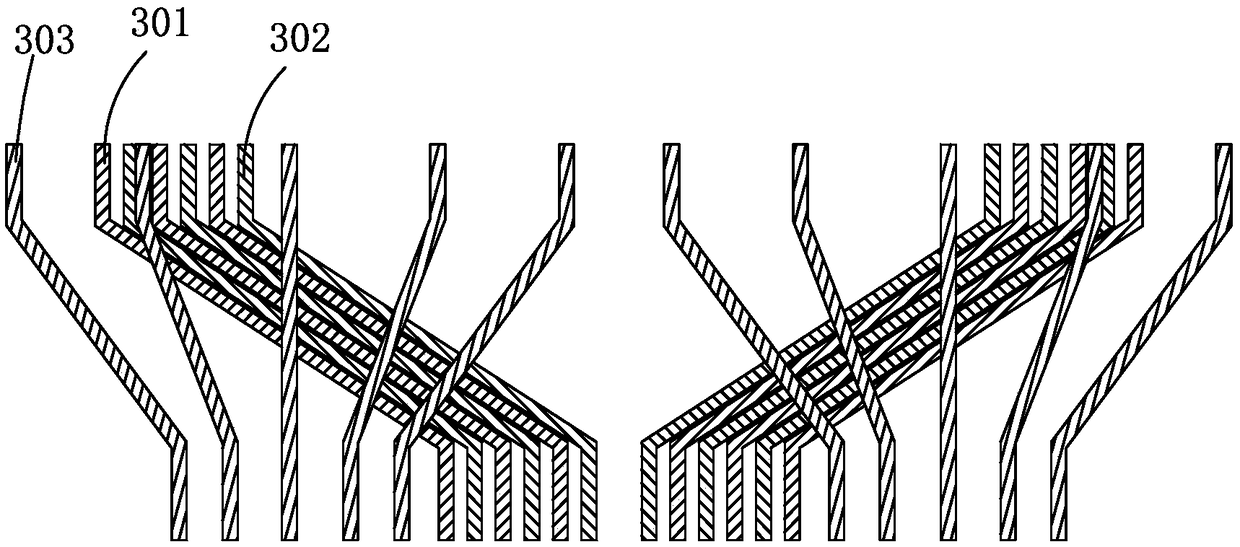

[0062] The substrate 100 includes an active display area 110 and a fan-out routing area 120 arranged in sequence. The first metal layer 200 includes a plurality of first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com