Lithium battery hot process space time modeling method based on dual-LS-SVM

A modeling method, lithium battery technology, applied in electrical digital data processing, character and pattern recognition, special data processing applications, etc., can solve problems such as difficult temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The spatio-temporal modeling method of thermal process of lithium battery based on dual LS-SVM in this embodiment:

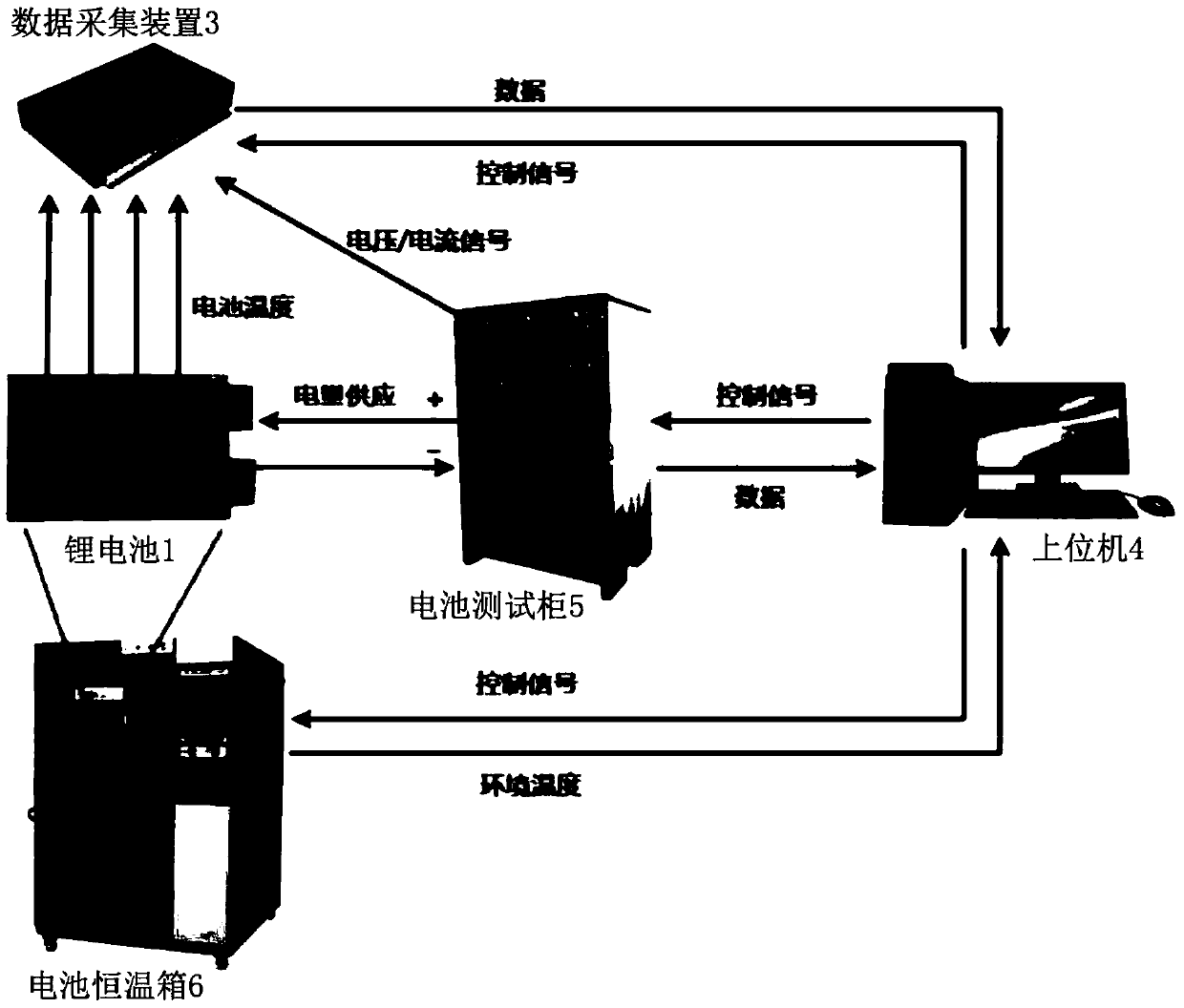

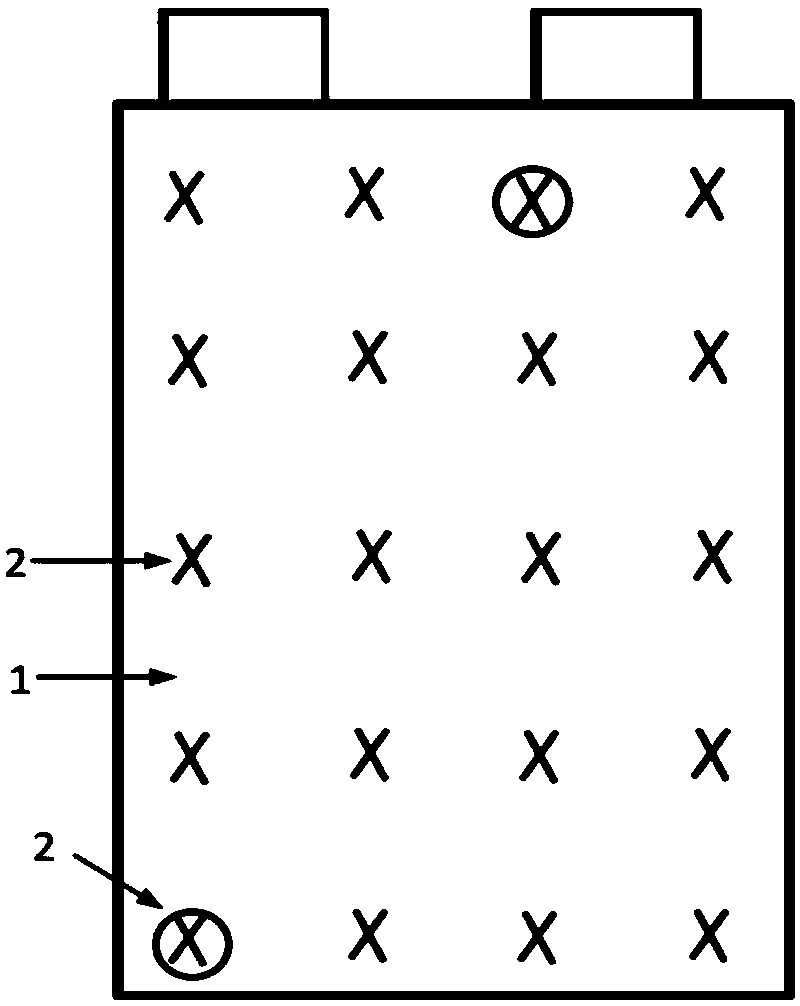

[0094] Step 1, build a lithium battery charge and discharge control platform, such as figure 1 , figure 2 As shown, a plurality of temperature sensors 2 are evenly arranged on the surface of the lithium battery 1, and the temperature data collected by each temperature sensor 2 is transmitted to the host computer 4 by the data acquisition device 3. The lithium battery 1 and the battery test cabinet 5 Electrically connected, the battery test cabinet 5 provides an input signal to the lithium battery 1 Make the lithium battery 1 cycle to charge and discharge;

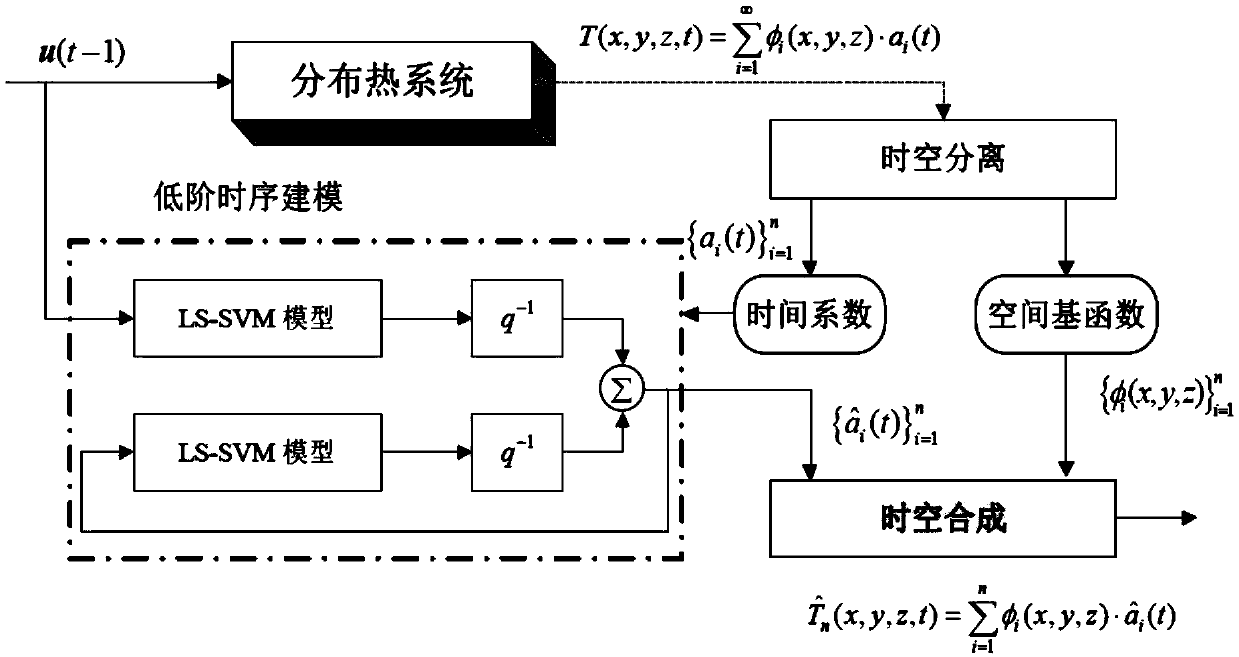

[0095] Step two, such as image 3 As shown, the upper computer 4 counts the temperature data of all temperature sensors 2, and obtains the time-space data of the temperature distribution of the lithium battery 1 under the condition of cycle charging and discharging with time, and defines the time-...

Embodiment 2

[0175] This example validates the proposed modeling method by conducting real-time experiments. The lithium battery 1 used is a 60Ah lithium iron phosphate battery purchased from a battery manufacturer in Shenzhen, China. This battery uses lithium iron phosphate as its positive electrode material, and has been successfully put into use in electric vehicles. Its basic parameters are shown in Table 1. Considering a flat prismatic 60Ah LiFePO 4 / graphite battery, a 2D thermal model is considered because the temperature variation along the thickness of the battery cell is negligible.

[0176]

[0177]

[0178] Table 1

[0179] The 60Ah lithium iron phosphate battery is a soft pack structure, and the top of the battery is the positive and negative tabs of the battery. The material used for the positive electrode tab is aluminum sheet, and the material used for the negative electrode tab is copper sheet. Its internal structure is a laminated structure, which is composed of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com