High-performance and high-coercivity Tb-containing magnet and preparation method thereof

A high-coercivity, high-performance technology, applied in the fields of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of increased production cost, complex process, difficult promotion and application, etc. Simple process and continuous grain boundary distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

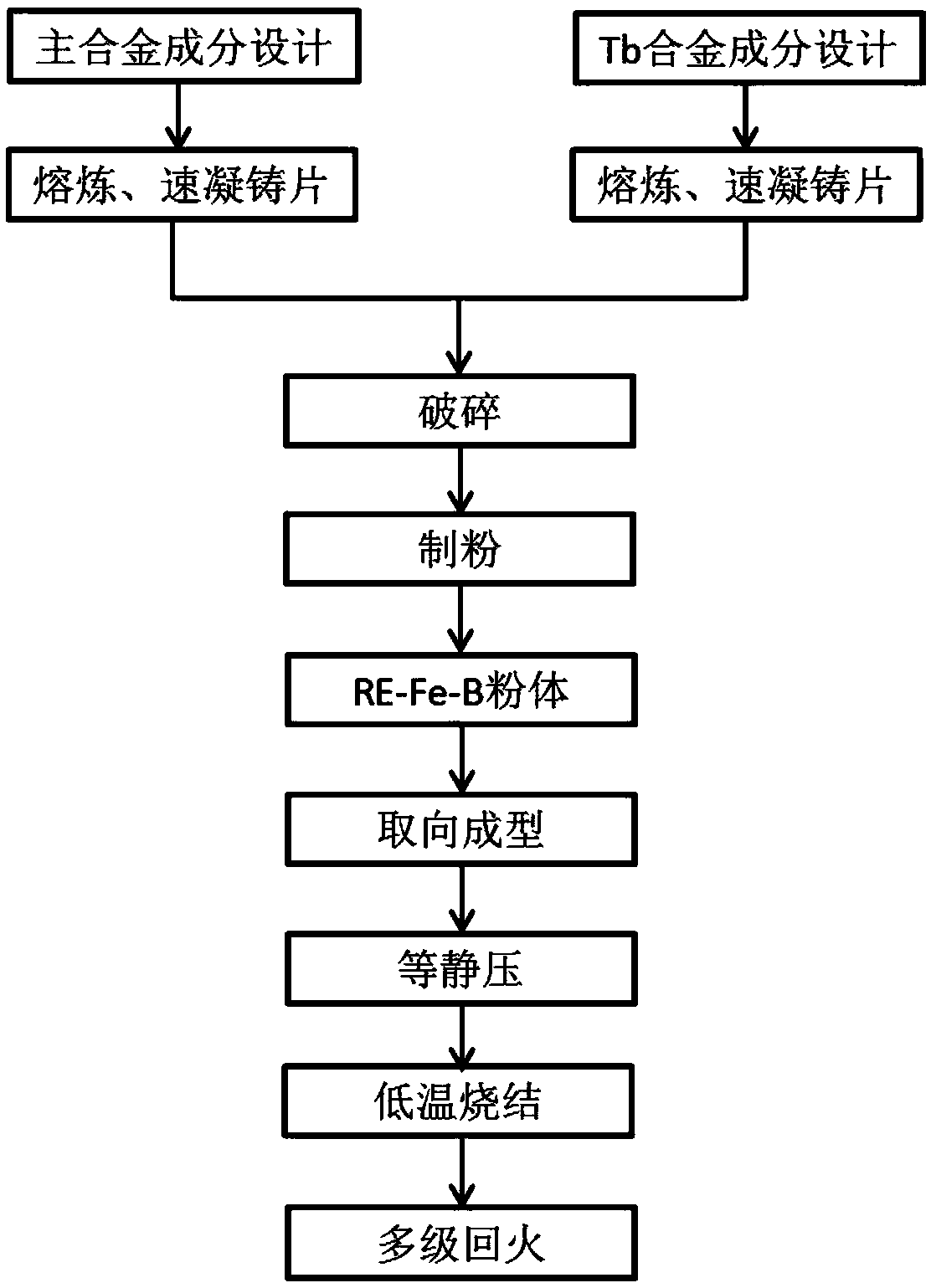

[0065] A kind of preparation method of Tb-containing high-performance high-coercivity magnet of the present invention comprises the following steps:

[0066] Step S1: configure the main phase alloy and Tb alloy according to the composition, and melt and quick-solidify to the main phase alloy cast sheet and the Tb alloy cast sheet;

[0067] Step S2: crushing and grinding the main phase alloy cast flakes and the Tb alloy cast flakes to obtain magnetic powder;

[0068] Step S3: Pressing and molding the magnetic powder to obtain a green body;

[0069] Step S4: performing low-temperature sintering and multi-stage tempering on the green body to obtain a magnet.

[0070] The above steps are the basic steps to obtain Tb-containing high-performance high-coercivity magnets.

[0071] The main phase alloy is RE-Fe-B alloy, Tb alloy is Tb-K alloy, where RE is one or a combination of Nd, Pr, Dy, and M is Co, Cu, Al, Ga, Nb One or a combination of several, K is one or a combination of Fe,...

Embodiment 2

[0107] In this example, the preparation method is as figure 1 As shown, wherein, in step S2, the first process scheme in Example 1 is adopted.

[0108] In step S1, the composition of the main phase alloy cast sheet obtained through smelting and rapid solidification is (PrNd) 30.3 Nb 0.4 Cu 0.2 Al 0.2 Fe 67.88 B 1.02 , the composition of Tb alloy cast sheet is Tb 85 Cu 15 , wherein the mass percentage of Tb in the Tb alloy is 85%.

[0109] In step S2, Tb alloy cast flakes with a mass percentage of 2.8% are added to the main phase alloy cast flakes, and crushed by hydrogen crushing method to obtain coarse powder with an average particle size of 220 μm; after grinding the coarse powder, the average Magnetic powder with a particle size of 2.92μm. In the milling process, the amount of oxygen added is 30ppm. Particle size detection is measured using a laser particle size analyzer.

[0110] In step S3, the magnetic powder is processed by vertical pressing and isostatic pre...

Embodiment 3

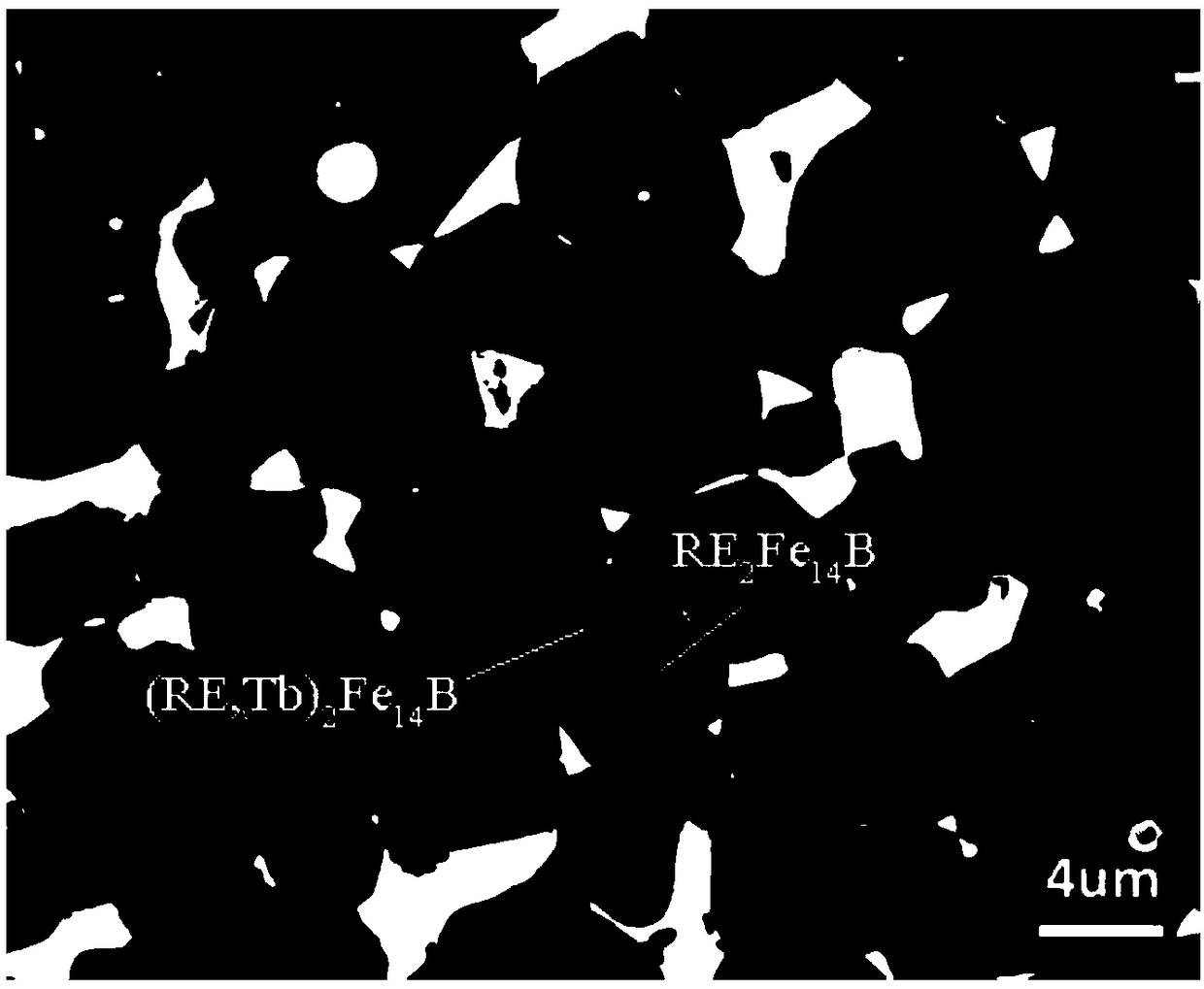

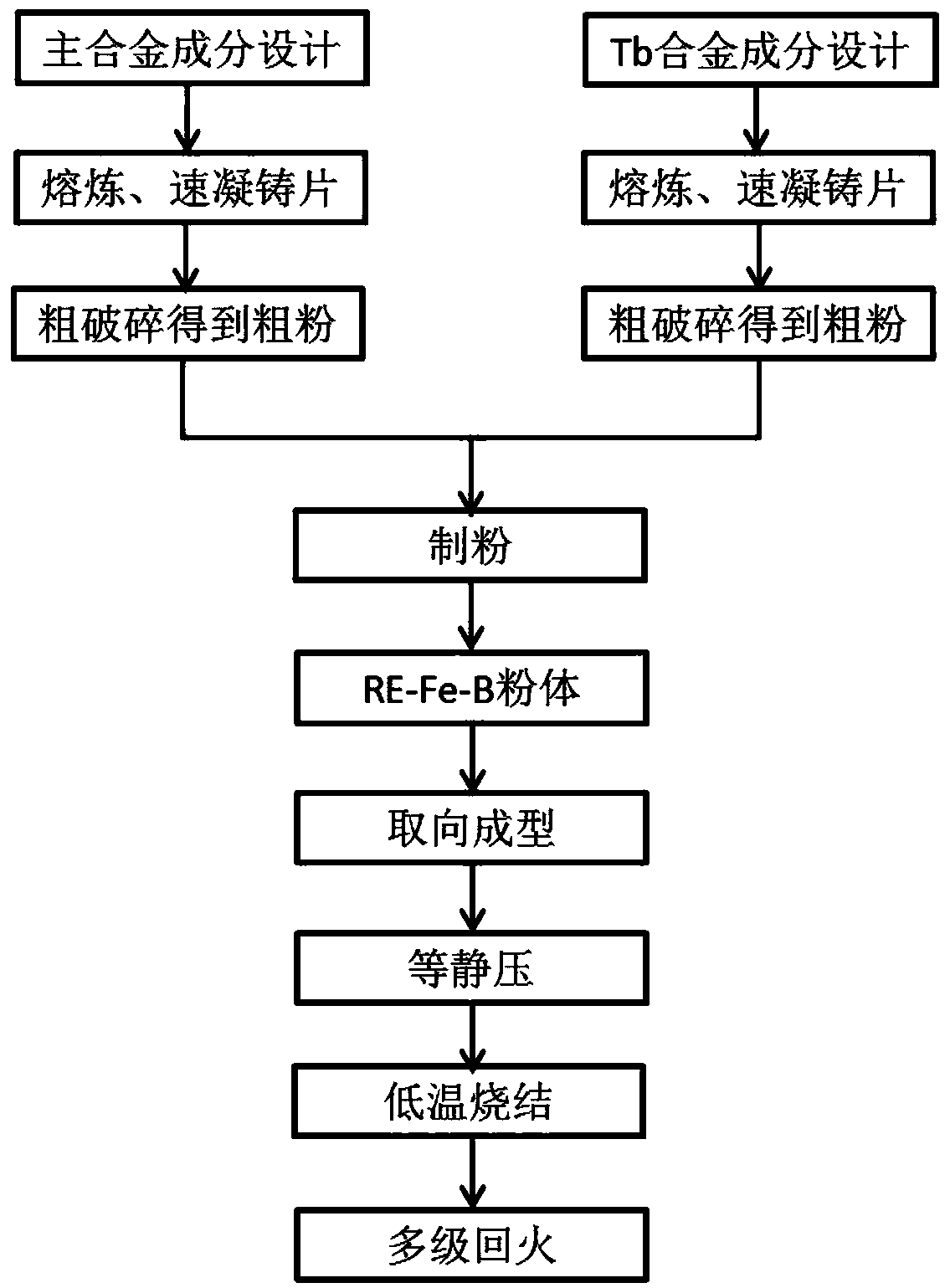

[0118] In this example, the preparation method is as image 3 As shown, wherein, in step S2, the second process scheme in embodiment 1 is adopted.

[0119] In step S1, the composition of the main phase alloy cast sheet obtained through smelting and rapid solidification is (PrNd) 28.01 Dy 1.89 Zr 0.17 Co1Cu 0.12 Al 0.1 Ga 0.25 Fe 67.56 B 0.91 , the Tb alloy casting composition is (PrNd) 15 Tb 72 Cu 3 Fe 10 , wherein the mass percentage of Tb in the Tb alloy is 72%.

[0120] The main phase alloy cast piece and the Tb alloy cast piece were broken respectively by the hydrogen crushing method to obtain a coarse powder with an average particle size of 180 μm; the Tb alloy coarse powder with a mass percentage of 4% was added to the main phase alloy coarse powder; for the mixed alloy After the coarse powder was ground, a magnetic powder with an average particle size of 2.79 μm was obtained. In the milling process, the amount of oxygen added is 35ppm. Particle size detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com