Solar cell piece and preparation method thereof and solar cell module

A technology of solar cells and solar cells, which is applied in the field of solar energy, and can solve problems such as increased number of scribing lines, large carrier transmission loss, and poor light transmittance of the film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

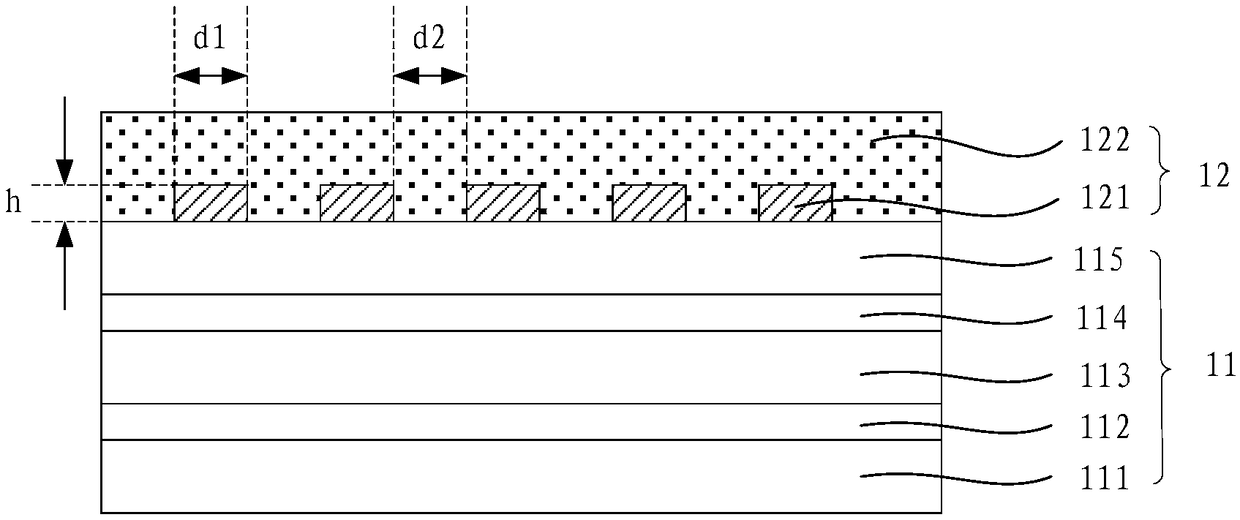

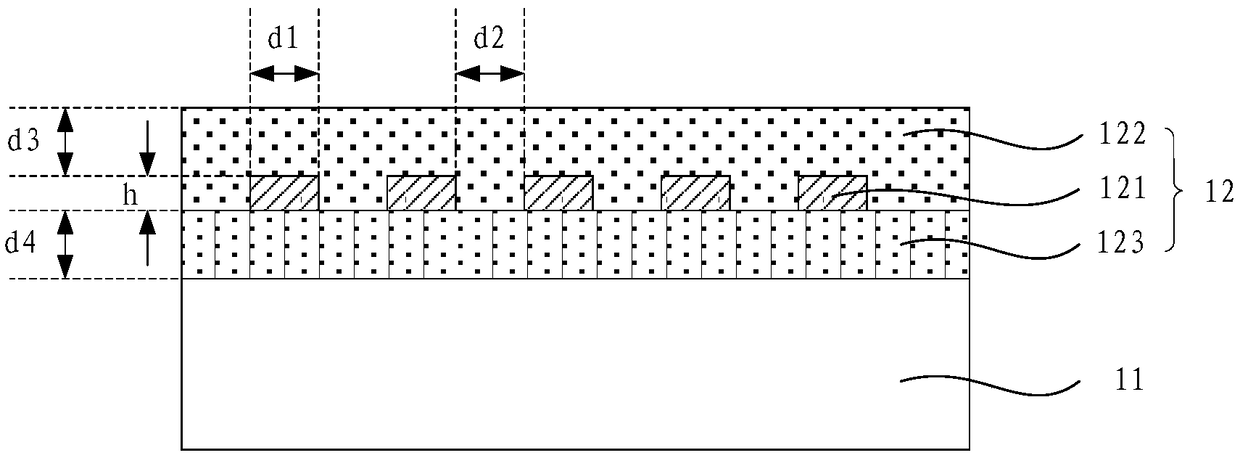

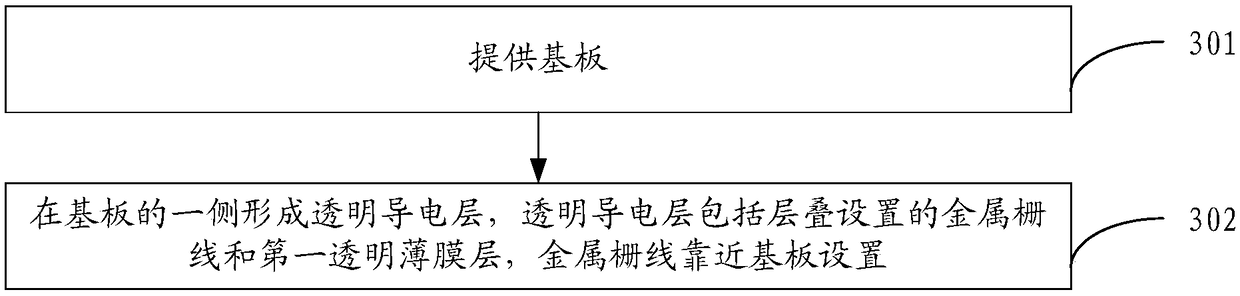

[0039] An embodiment of the present application provides a solar battery sheet, referring to figure 1 , the solar battery sheet may include: a substrate 11 and a transparent conductive layer 12 formed on one side of the substrate 11, the transparent conductive layer 12 includes metal grid lines 121 and a first transparent film layer 122 stacked, and the metal grid lines 121 are close to the substrate 11 set up.

[0040] In the solar battery sheet provided by this embodiment, by arranging metal grid lines with low resistivity in the transparent conductive layer, the ability of the transparent conductive layer to collect carriers can be greatly improved, the resistance of the transparent conductive layer can be reduced, and the sola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com