Pre-ionization trigger rod and gas switch using the trigger rod

A gas switch and trigger lever technology, which is applied to spark gaps, electrical components, circuits and other directions with auxiliary trigger devices, can solve the problems of insufficient compact structure, unstable switch breakdown mode, and insufficient discharge stability, and achieves simple structure, The triggering method is simple and effective, and the insulation margin is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

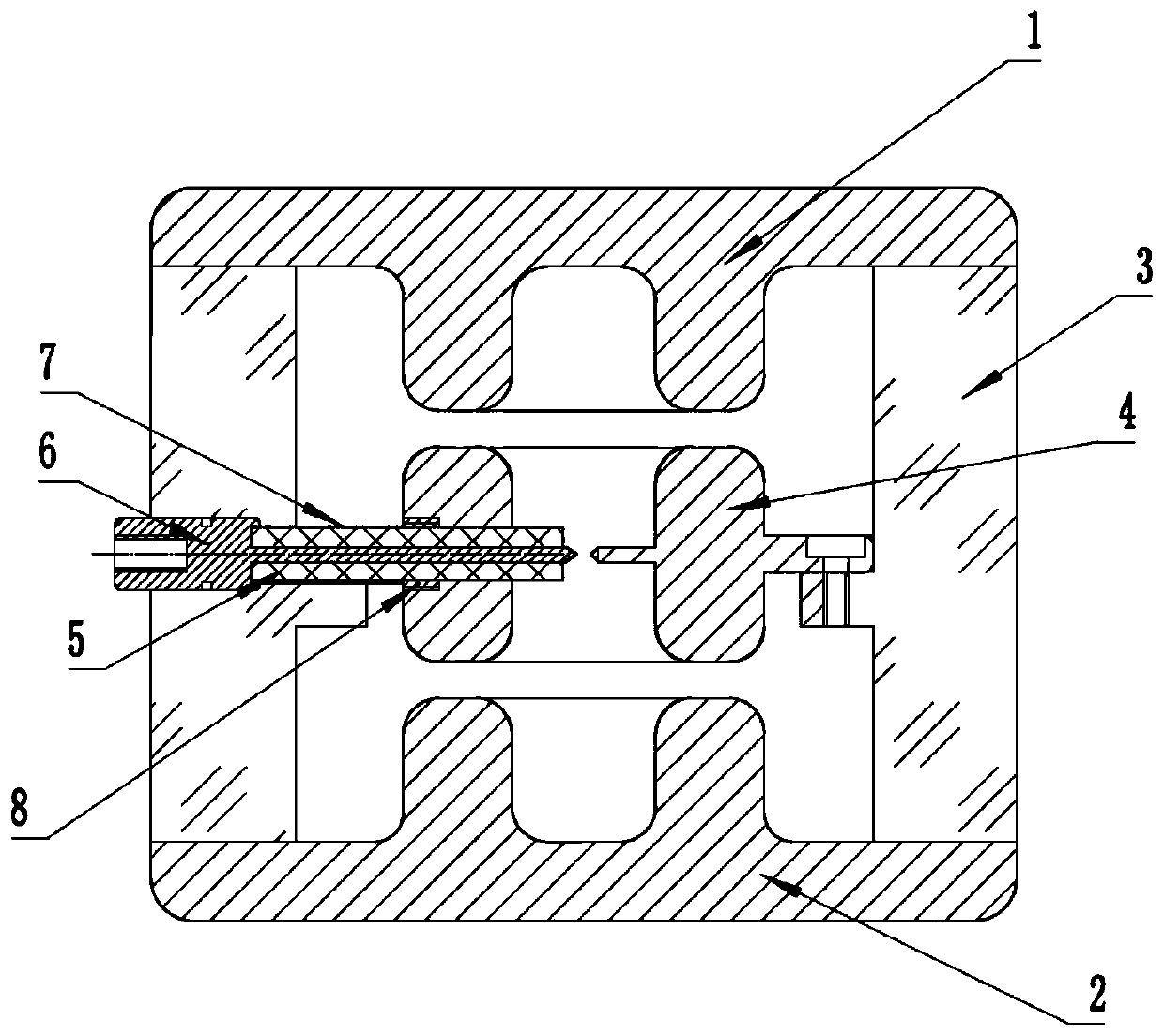

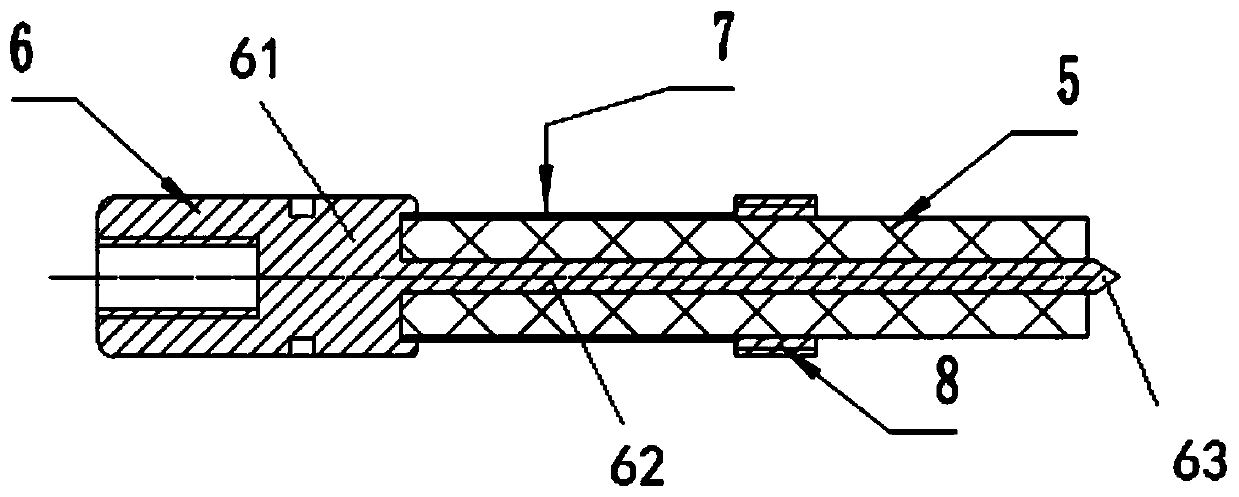

[0044] like figure 1 As shown, the gas switch provided by the present invention includes a trigger rod and an electrode structure; the electrode structure includes an upper high voltage electrode 1, a lower high voltage electrode 2, an insulating cylinder 3 and a middle trigger electrode 4; the middle trigger electrode is arranged on the upper high voltage electrode and the lower high voltage electrode Between; the insulating cylinder is set at the edge position between the upper high-voltage electrode and the lower high-voltage electrode for sealing, insulation and support;

[0045] The upper high-voltage electrode 1 and the lower high-voltage electrode 2 are made of stainless steel, and the section of the discharge part is semicircular. The insulation cylinder 3 is made of insulating materials such as plexiglass and nylon, and a trigger introduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com