Method for producing a short circuit rotor and short circuit rotor

A short-circuit, rotor technology, used in the manufacture of squirrel-cage rotors, tools, motor generators, etc., can solve problems such as low strength and electrical conductivity, and achieve the effect of reducing heat input and increasing spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

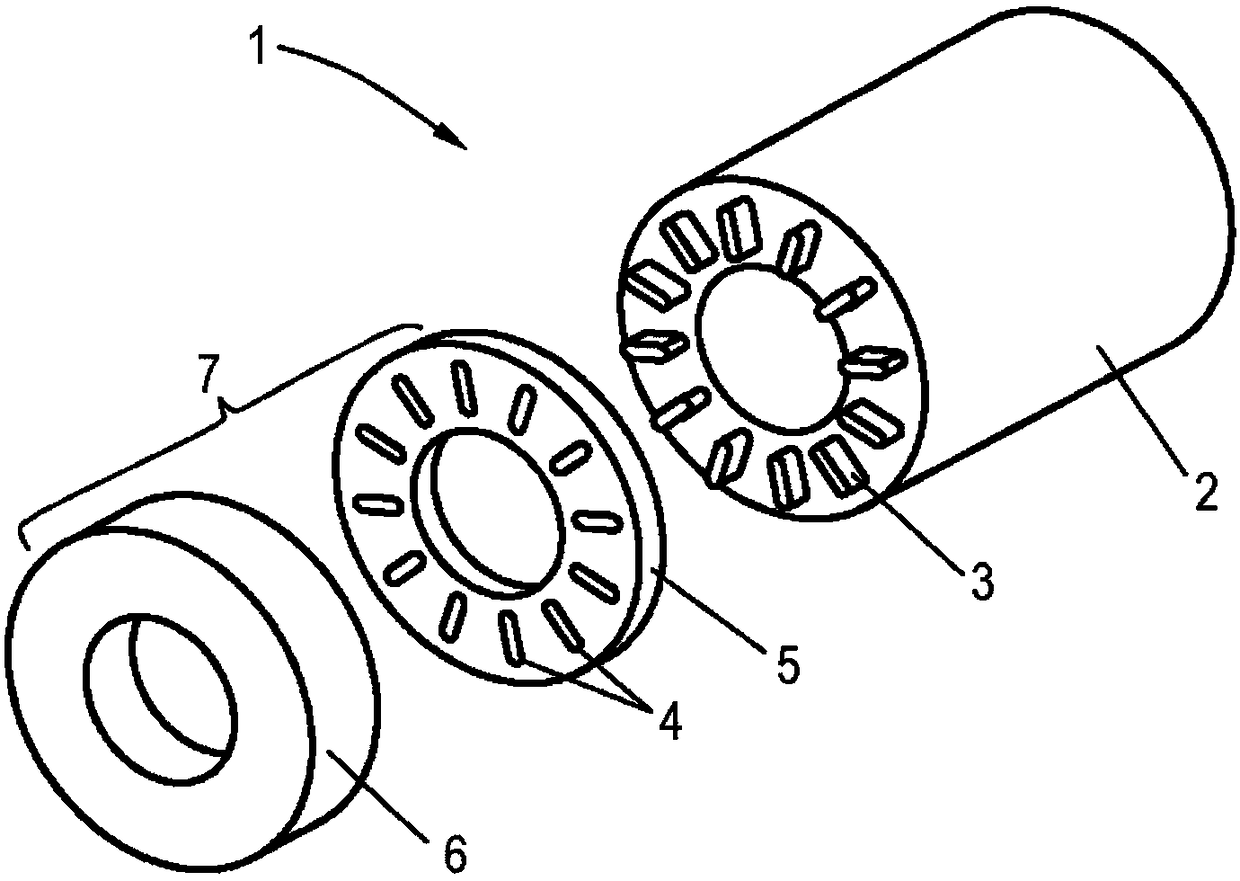

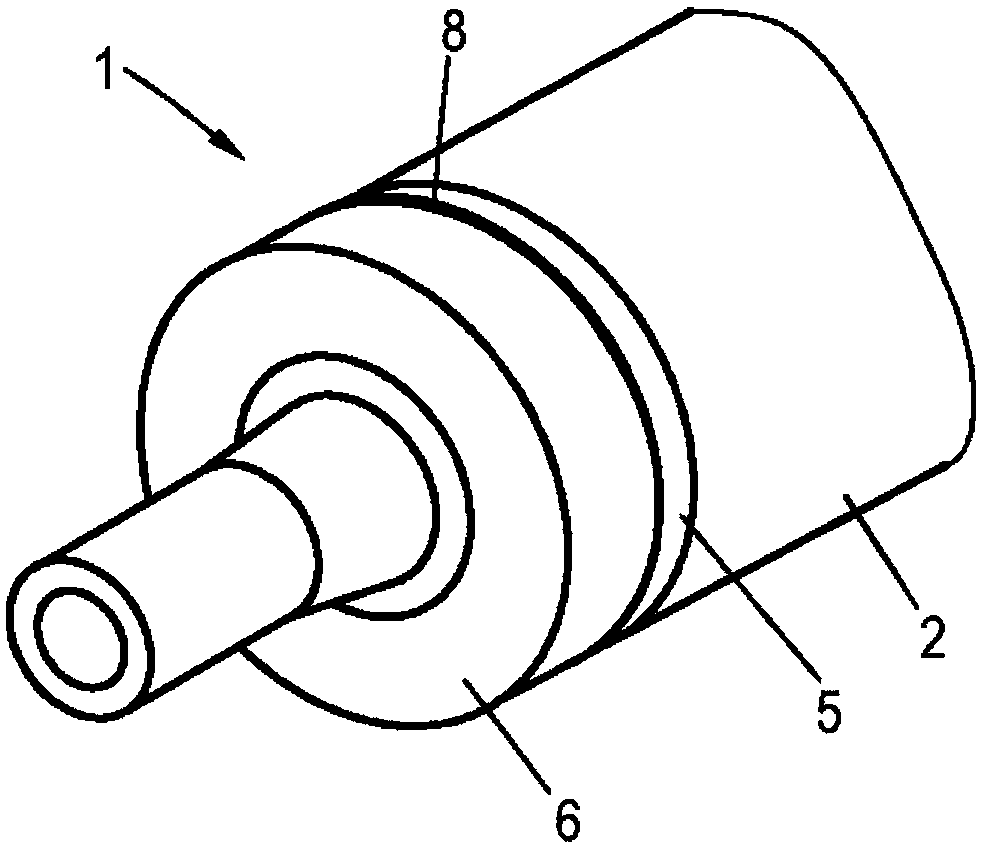

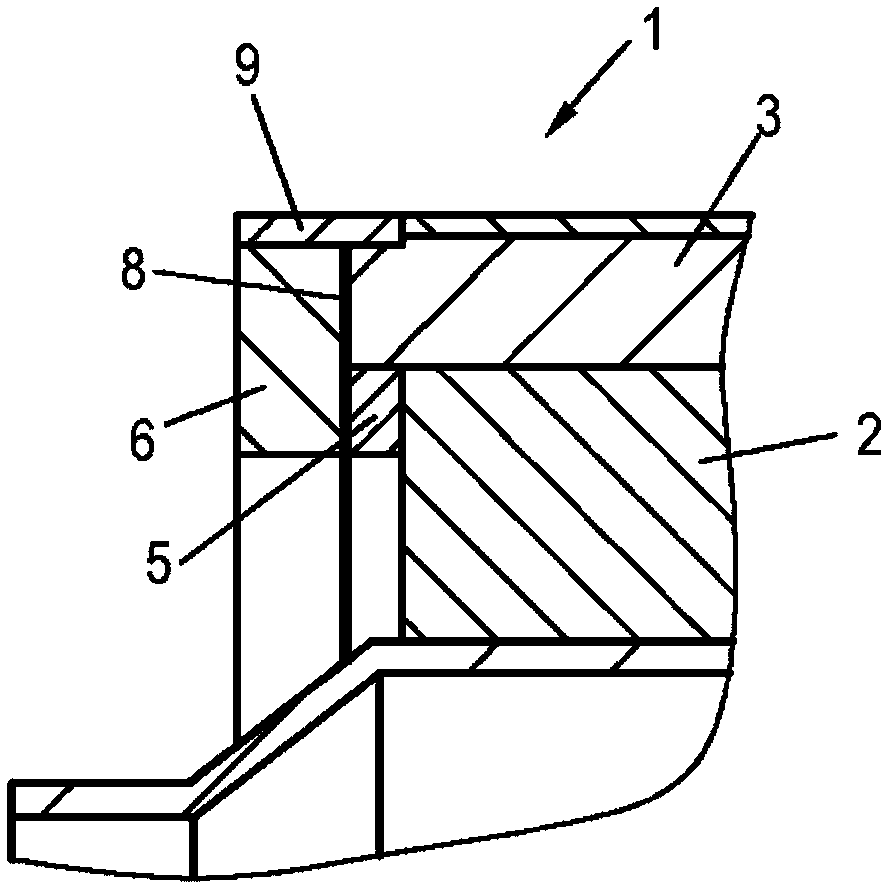

[0031] figure 1 The main components of one side of the short-circuit rotor 1 according to the invention are shown in an exploded view, the axially opposite side (not shown) of the short-circuit rotor 1 being formed mirror-symmetrically here. Before joining the components of the short-circuit rotor shown here, the short-circuit rotor 1 has a rotor core 2 as is basically known from the prior art. The rotor core 2 has through-openings, into which the short-circuit bars 3 of the squirrel-cage of the short-circuited rotor 1 have been inserted. The shorting bar 3 protrudes significantly axially on both sides in order to be able to engage in a form-fitting manner in the through-opening or recess 4 of the main ring 5 . The axial end of the short-circuiting rotor 1 is formed by the outer ring 6 , which has no recesses or holes for the short-circuiting bars 3 , whereby the short-circuiting bars are to rest materially on the outer ring. The main ring sheet 5 and the outer edge ring she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com