Preparation method and applications of feed

A feed and material technology, applied in application, animal feed, animal feed, etc., can solve the problems of affecting production performance, slow growth of piglets, increasing the number of stillbirths, etc., to improve digestion and utilization, attract food with long-lasting fragrance, and improve palatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

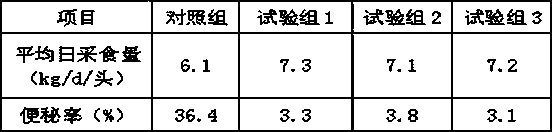

Examples

Embodiment 1

[0074] A method for preparing a feed, comprising the steps of:

[0075] Step (1): Weigh 25 parts by weight of cypress kernel powder, 10 parts by weight of cistanche powder, 20 parts by weight of corn sprout powder, and 6 parts by weight of oligosaccharides, and weigh the cypress kernel powder, cistanche powder, and corn sprout powder Mix evenly with oligosaccharides to prepare composite material A; the oligosaccharides are fructooligosaccharides.

[0076] Step (2): Weighing 40 parts by weight of corn flour, and subjecting the weighed corn flour to microwave puffing to obtain puffed material B;

[0077] Step (3): Weigh 20 parts by weight of jujube powder, add the weighed jujube powder to the puffed material B prepared in step (2) and mix evenly, cool and dry the evenly mixed material to obtain a compound Material C;

[0078] Step (4): adding composite material A prepared in step (1) and composite material C prepared in step (3) into a mixer, and mixing uniformly to obtain com...

Embodiment 2

[0090] A method for preparing a feed, comprising the steps of:

[0091] Step (1): Weigh 17 parts by weight of cypress kernel powder, 5 parts by weight of cistanche powder, 14 parts by weight of corn sprout powder, and 2 parts by weight of oligosaccharides, and weigh the cypress kernel powder, cistanche powder, and corn sprout powder Mix evenly with oligosaccharides to prepare composite material A; the oligosaccharides are chitosan oligosaccharides.

[0092] Step (2): Weighing 60 parts by weight of corn flour, and subjecting the weighed corn flour to microwave puffing to obtain puffed material B;

[0093] Step (3): Weigh 15 parts by weight of jujube powder, add the weighed jujube powder to the puffed material B prepared in step (2) and mix evenly, cool and dry the evenly mixed material to obtain a compound Material C;

[0094] Step (4): adding composite material A prepared in step (1) and composite material C prepared in step (3) into a mixer, and mixing uniformly to obtain c...

Embodiment 3

[0106] A method for preparing a feed, comprising the steps of:

[0107] Step (1): Weigh 10 parts by weight of cypress kernel powder, 7.5 parts by weight of cistanche powder, 8 parts by weight of corn sprout powder, and 10 parts by weight of oligosaccharides, and weigh the cypress kernel powder, cistanche desertica powder, and corn sprout powder and oligosaccharides are evenly mixed to obtain composite material A; the oligosaccharides are mannan oligosaccharides.

[0108] Step (2): Weighing 50 parts by weight of corn flour, and subjecting the weighed corn flour to microwave puffing to obtain puffed material B;

[0109] Step (3): Weigh 10 parts by weight of jujube powder, add the weighed jujube powder to the puffed material B prepared in step (2) and mix evenly, cool and dry the evenly mixed material to obtain a compound Material C;

[0110] Step (4): adding composite material A prepared in step (1) and composite material C prepared in step (3) into a mixer, and mixing uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com