Oyster fattening bait produced by agricultural and marine product wastes and preparation method thereof

A waste and product technology, applied in the field of oyster fattening bait and its preparation, can solve the problems of uncontrollable oyster fat and thin, low survival rate of oysters, insufficient fattening effect, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

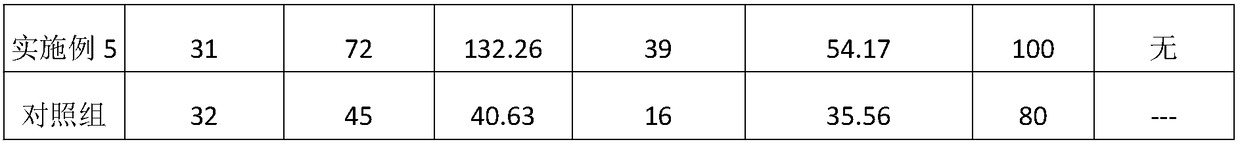

Examples

Embodiment 1

[0037] The preparation of a fattening bait for oysters produced from agricultural and seafood waste includes the following steps:

[0038] (1) Weigh according to the required weight: 10 parts of corn husk, 10 parts of apple pomace, 10 parts of scallop offal, 5 parts of shrimp bran powder, 5 parts of squid offal powder, 5 parts of oyster shell powder, 10 parts of seaweed powder; Seaweed powder is a mixture of sargassum powder and ulva powder at a weight ratio of 1:1; scallop offal, shrimp bran powder, and squid offal powder are pulverized dry powder; corn husk is corn oil extracted from vegetable oil plants , Corn starch and corn gluten powder; apple pomace is the pomace after apple juice; oyster shell powder is obtained by crushing oyster shell.

[0039] (2) After the corn husks, apple pomace, scallop offal, shrimp bran powder, squid offal powder, oyster shell powder and seaweed powder weighed in step (1) are evenly mixed, the coarse powder is mixed;

[0040] (3) The mixed coarse po...

Embodiment 2

[0045] The preparation of a fattening bait for oysters produced from agricultural and seafood waste includes the following steps:

[0046] (1) Weigh according to the required parts by weight: 20 parts of corn husk, 20 parts of apple pomace, 20 parts of scallop offal, 10 parts of shrimp bran powder, 10 parts of squid offal powder, 10 parts of oyster shell powder, 30 parts of seaweed powder; Seaweed powder is a mixture of sargassum powder and ulva powder at a weight ratio of 1:1; scallop innards, shrimp bran powder, and squid offal powder are pulverized dry powder; corn husk is corn oil extracted from vegetable oil plants , Corn starch and corn gluten meal; apple pomace is the pomace after apple juice; oyster shell powder is obtained by crushing oyster shell.

[0047] (2) After the corn husks, apple pomace, scallop offal, shrimp bran powder, squid offal powder, oyster shell powder and seaweed powder weighed in step (1) are evenly mixed, the coarse powder is mixed;

[0048] (3) The mix...

Embodiment 3

[0053] The preparation of a fattening bait for oysters produced from agricultural and seafood waste includes the following steps:

[0054] (1) Weigh according to the required parts by weight: 12 parts of corn husk, 12 parts of apple pomace, 12 parts of scallop offal, 6 parts of shrimp bran powder, 6 parts of squid offal powder, 6 parts of oyster shell powder, 15 parts of seaweed powder; Seaweed powder is a mixture of sargassum powder and ulva powder at a weight ratio of 1:1; scallop offal, shrimp bran powder, and squid offal powder are pulverized dry powder; corn husk is corn oil extracted from vegetable oil plants , Corn starch and corn gluten powder; apple pomace is the pomace after apple juice; oyster shell powder is obtained by crushing oyster shell.

[0055] (2) After the corn husks, apple pomace, scallop offal, shrimp bran powder, squid offal powder, oyster shell powder and seaweed powder weighed in step (1) are evenly mixed, the coarse powder is mixed;

[0056] (3) The mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com