Production device of chloro-methoxy fat diethylene glycol dinitrate

A chloromethoxy fatty acid methyl ester and a production device technology, which is applied in the field of chloromethoxy fatty acid methyl ester production equipment, can solve the problems of difficult to determine what to remove impurities, low purity, high capital investment, etc., and achieve simple production process Easy to understand, simple process, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

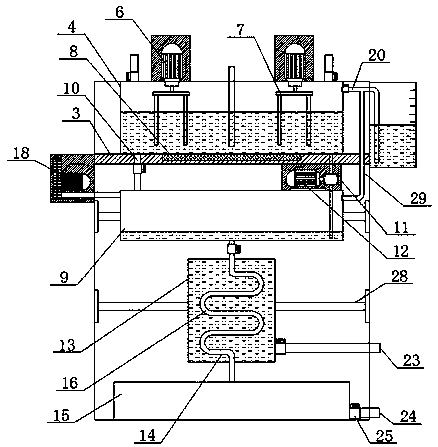

[0022] As a preferred embodiment of the present invention, the water pump 12 is respectively connected to the reaction tank 4 and the auxiliary tank 9 through water pipes.

[0023] As a preferred embodiment of the present invention, the air pump 18 is connected to the auxiliary tank 9 through an exhaust pipe.

[0024] As a preferred embodiment of the present invention, the first air duct 20 is welded with the second air duct 29 , and one end of the second air duct 29 is connected to the auxiliary box 9 .

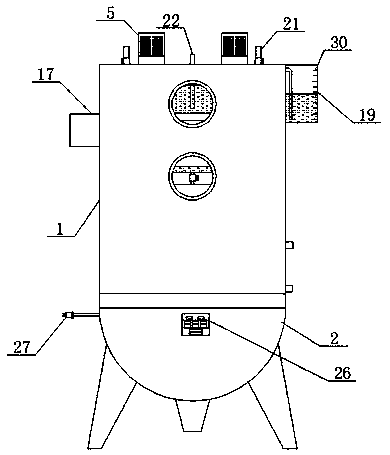

[0025] As a preferred embodiment of the present invention, the detection box 19 is engraved with a scale line 30 .

[0026] Working principle: When using chloromethoxy fatty acid methyl ester to make the device, first connect the wiring plug 27 to an external power supply, so as to provide power for the electrical appliances, and then open the electric valve 25 on the feed pipe 21 through the switch group 26 , divide the proportioned biodiesel and methane into two parts and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com