Potato slicing device

A technology of slicing device and potatoes, applied in metal processing and other directions, can solve the problems of inconvenient tool cleaning, influence of potato chips, blackening, etc., and achieve the effects of reducing operation difficulty, improving utilization rate, and preventing oxidation and blackening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

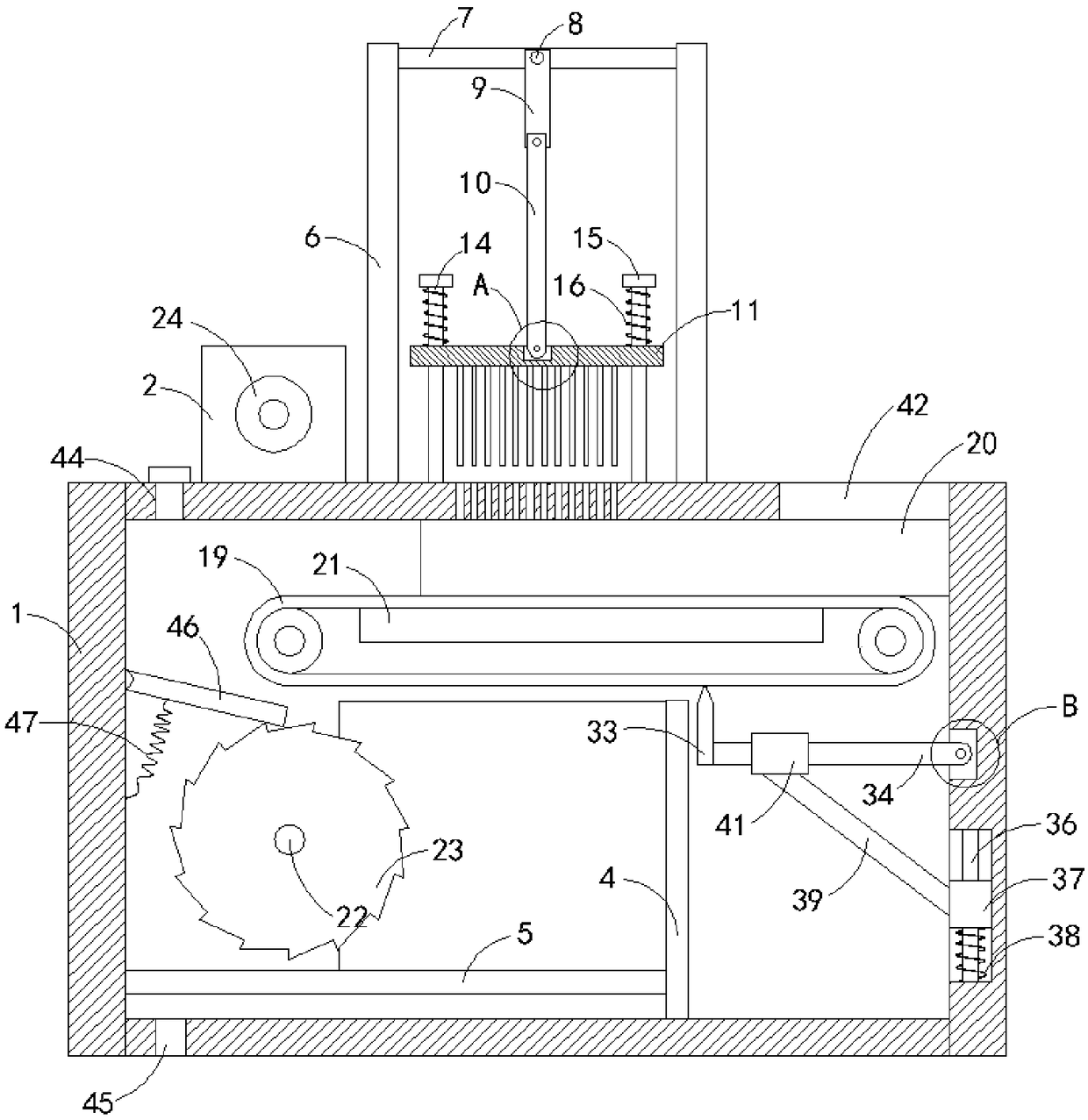

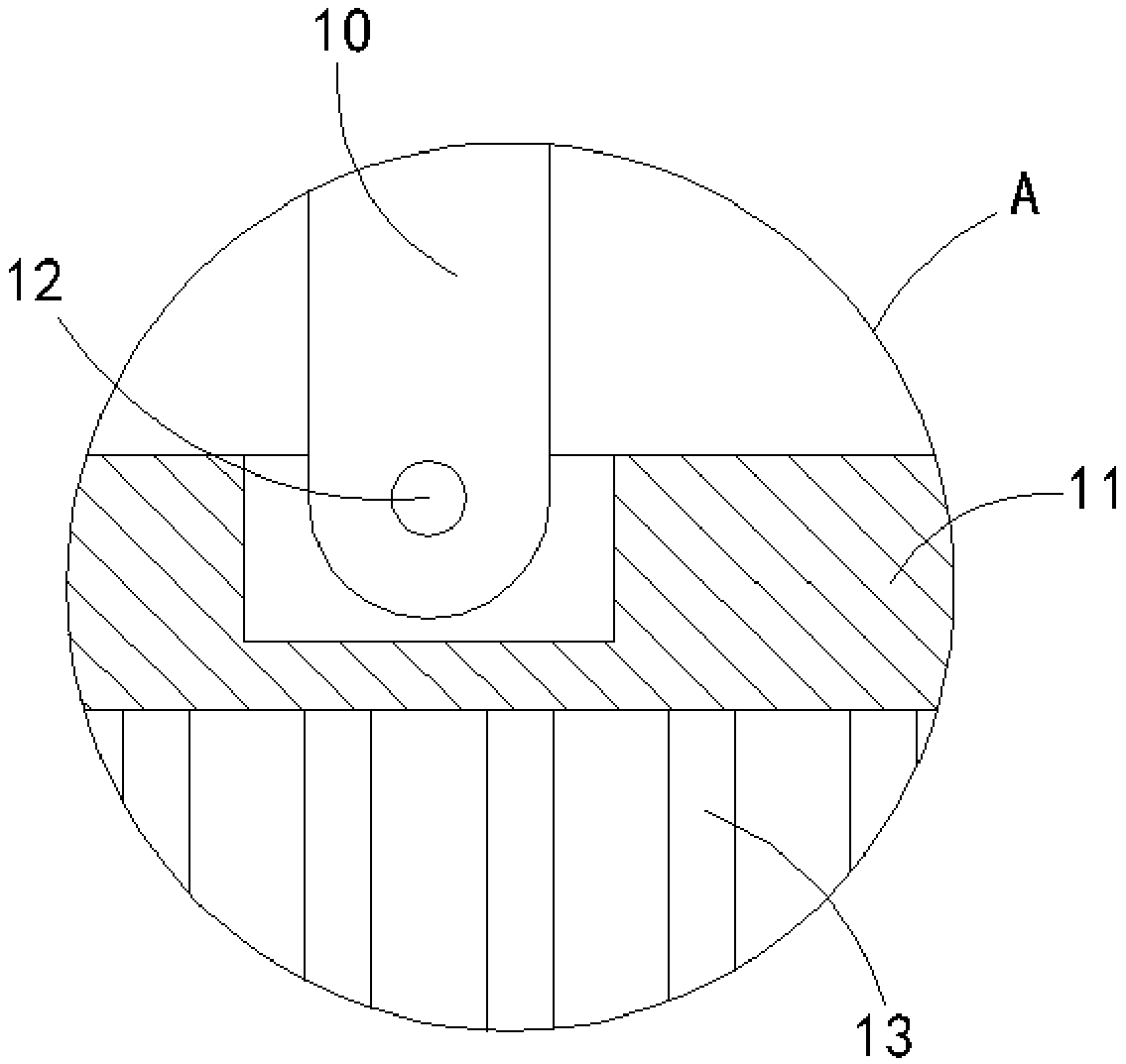

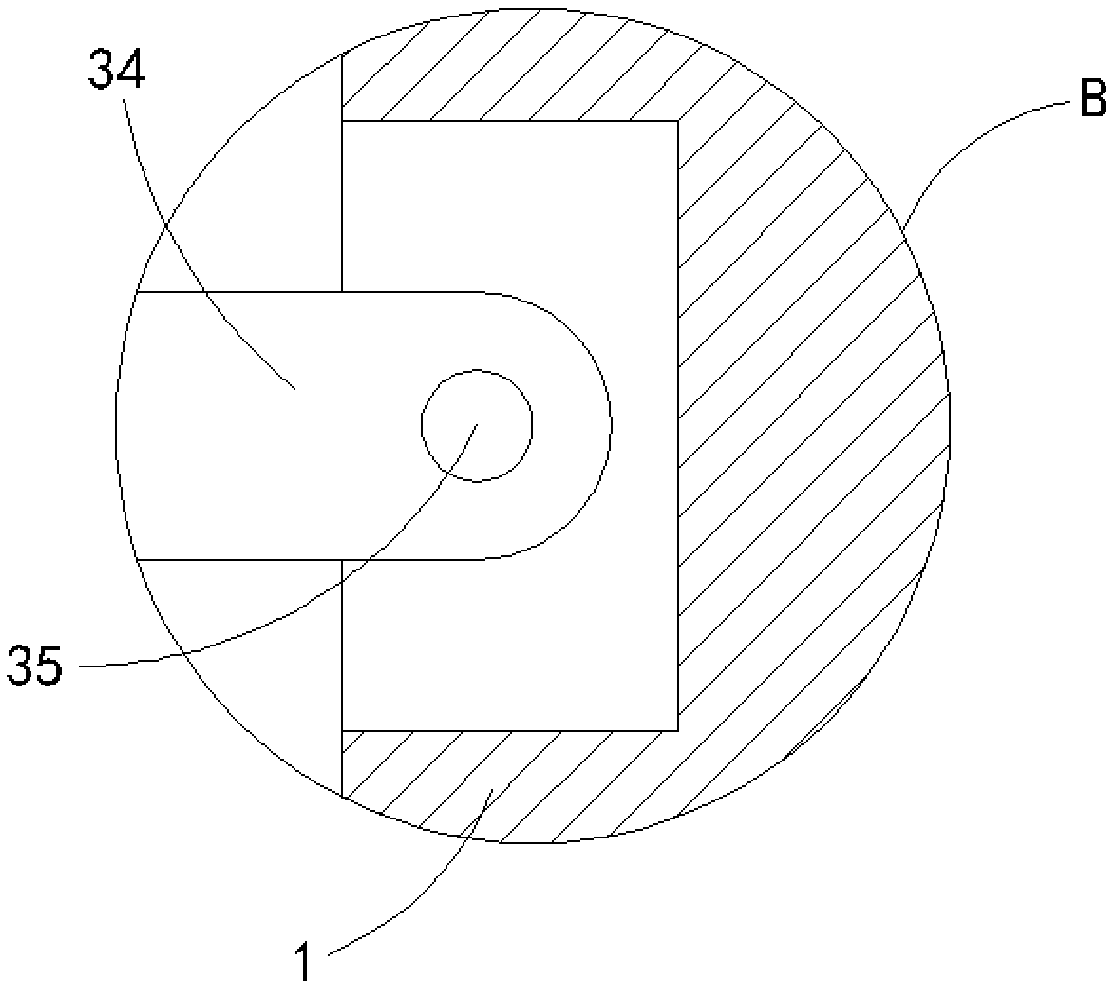

[0022] Such as Figure 1-5 As shown, a potato slicing device includes a box body 1. It should be noted that the upper end of the box body 1 is provided with a water inlet 44, the lower end of the box body 1 is provided with a water outlet 45, and the side wall of the box body 1 is provided with The vertically arranged strip-shaped opening, the transparent plate 40 is installed in the strip-shaped opening, can be used to observe the situation in the box body 1, the upper end of the box body 1 is provided with a slicing mechanism, and the upper end of the box body 1 is equipped with a biaxial motor 2, The double-axis motor 2 is connected to the slicing mechanism through the first transmission mechanism. The upper end of the box body 1 is provided with a material inlet 42, and the side wall of the box body 1 is provided with a material outlet 43. A side door 3 is hinged inside the material outlet 43. , the side door 3 is sealed and connected with the box body 1, the box body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com