A method for preparing composite material pipe by using inner expansion method forming mold

A composite material tube and forming die technology, which is applied in the field of aviation composite material forming, can solve the problems of difficult forming of composite material tubes, and achieve the effects of uniform wall thickness, convenient operation, overcoming difficult sealing and easy air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

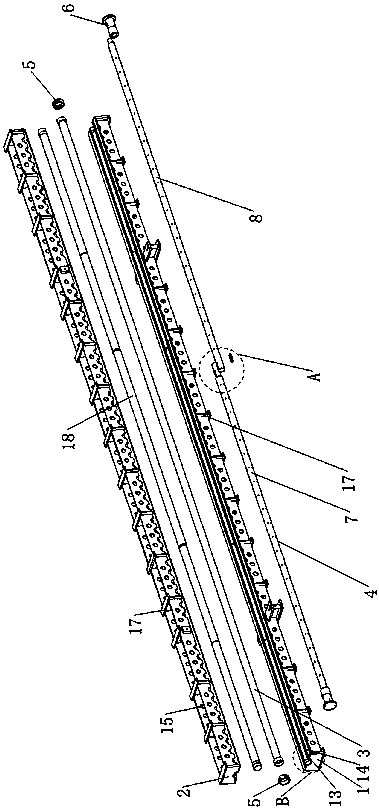

[0038] Specific implementation mode one: as Figure 1-Figure 5 As shown, this embodiment discloses a method for preparing a composite material pipe using an internal expansion molding die, and the method includes the following steps:

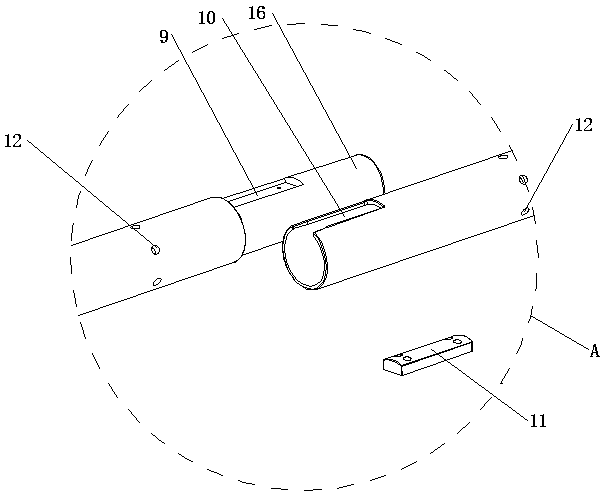

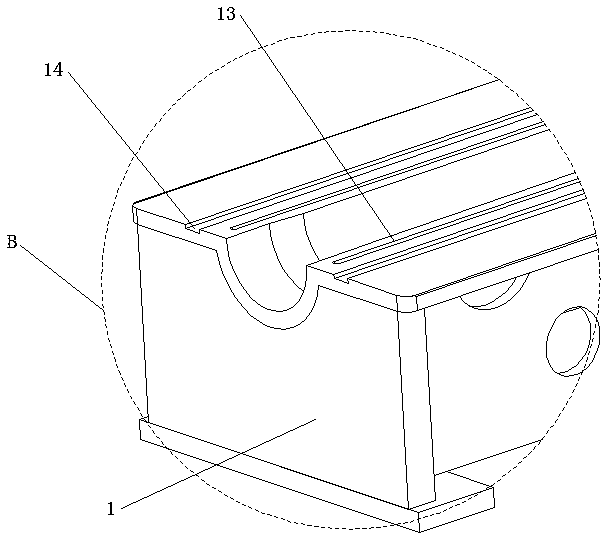

[0039] Step 1: the connection of metal mandrel 1 7 and metal mandrel 2 8; metal mandrel 1 7 and metal mandrel 2 8 are metal round tubes, and the outer pipe diameters are the same, and the cone set at one end of metal mandrel 7 is Type connection boss 16 is matched with the taper hole that metal mandrel two 8 one ends are provided with, and the retaining groove one 9 that is provided with on the tapered connection boss 16 outer wall of metal mandrel one 7 is provided with metal mandrel two 8 places The retaining groove 2 10 that is provided with at one end is oppositely arranged and embedded in the retaining key 11 (to prevent the metal mandrel 1 7 and the metal mandrel 2 8 from rotating mutually), and the metal mandrel 1 7 other end is provided ...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment is a further description of Embodiment 1. In step 3 of this embodiment, when the ambient temperature and humidity conditions meet the requirements, the temperature is 18-22° C. and the humidity is less than 25-30%. The purpose is to avoid ply defects.

specific Embodiment approach 3

[0051] Specific embodiment three: This embodiment is a further description of specific embodiment one or two. In step six of this embodiment, the preparation method of the vacuum bag is: paste a circle of putty strips on the bag-making area, and then paste the vacuum film , and then connect the air source to the vacuum nozzle connected to the vacuum membrane for vacuuming.

[0052] The retaining key 11 used in the present invention is a cylindrical connection key.

[0053] In the present invention, both the lower mold body 1 and the upper mold body 2 are provided with hoisting rings 19 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com