Preparation method of heterostructure porous graphene oxide membrane, graphene membrane and generator

A technology of graphene film and heterostructure, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., to achieve the effects of strong electricity production capacity, improved practicability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

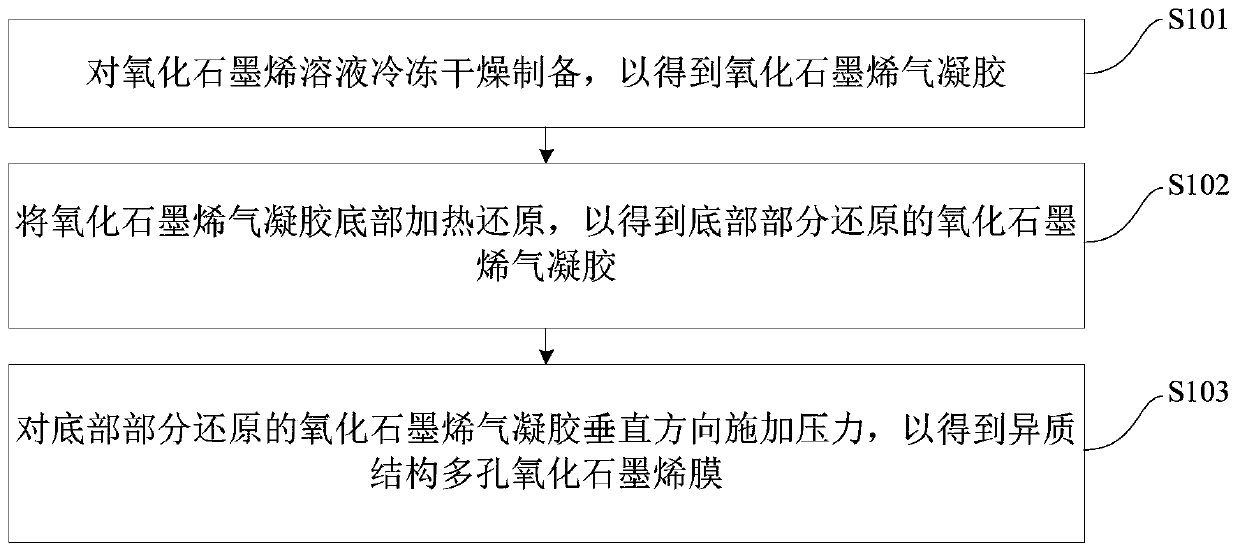

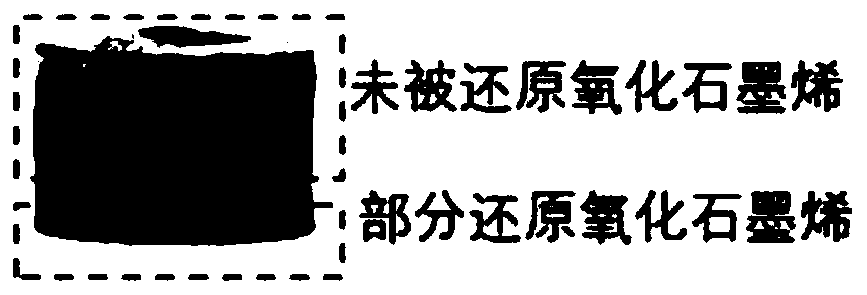

[0041] Such as figure 1 Shown, this heterostructure porous graphene oxide membrane preparation method comprises the following steps:

[0042] In step S101, the graphene oxide solution is freeze-dried to obtain graphene oxide airgel.

[0043] It can be understood that, in the embodiment of the present invention, the graphene oxide solution (3-15 mg / mL) is freeze-dried by the freeze-drying method to prepare the graphene oxide airgel (3-15 mg / cm 3 ). Wherein, the freeze-drying time is 24-72 hours.

[0044]Further, in one embodiment of the present invention, the preparation process of the graphene oxide solution includes: stirring and mixing 9g of graphite powder, 240mL of concentrated sulfuric acid, and 4.5g of sodium nitrate in an ice bath; adding 27g of potassium permanganate , and continue to stir for 1 hour; stir for two hours after raising the temperature to 30 ° C, and add 450 mL of deionized water after stirring; stir for 20 minutes after raising the temperature to 90 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com