A production process of ag glass

A production process and glass technology, applied in the field of AG glass production process, can solve problems such as glass damage and affecting glass quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

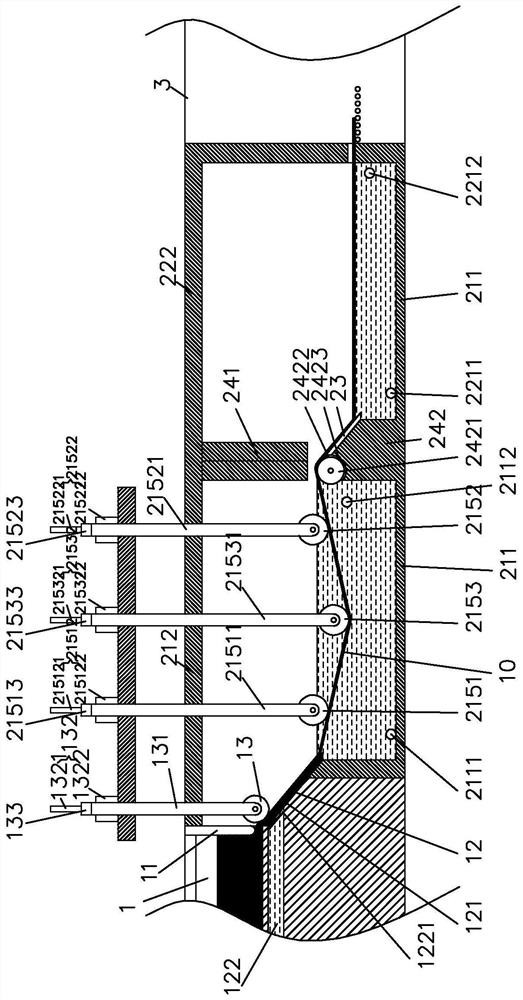

[0057] A kind of production technology of AG glass of the present invention, as Figure 1-6 shown, including the following steps:

[0058] (1) Melting the glass raw material by using the melting furnace 1 to form a glass fluid;

[0059] (2) Carry out float method formation to the glass fluid by melting the tin room to form the early glass plate;

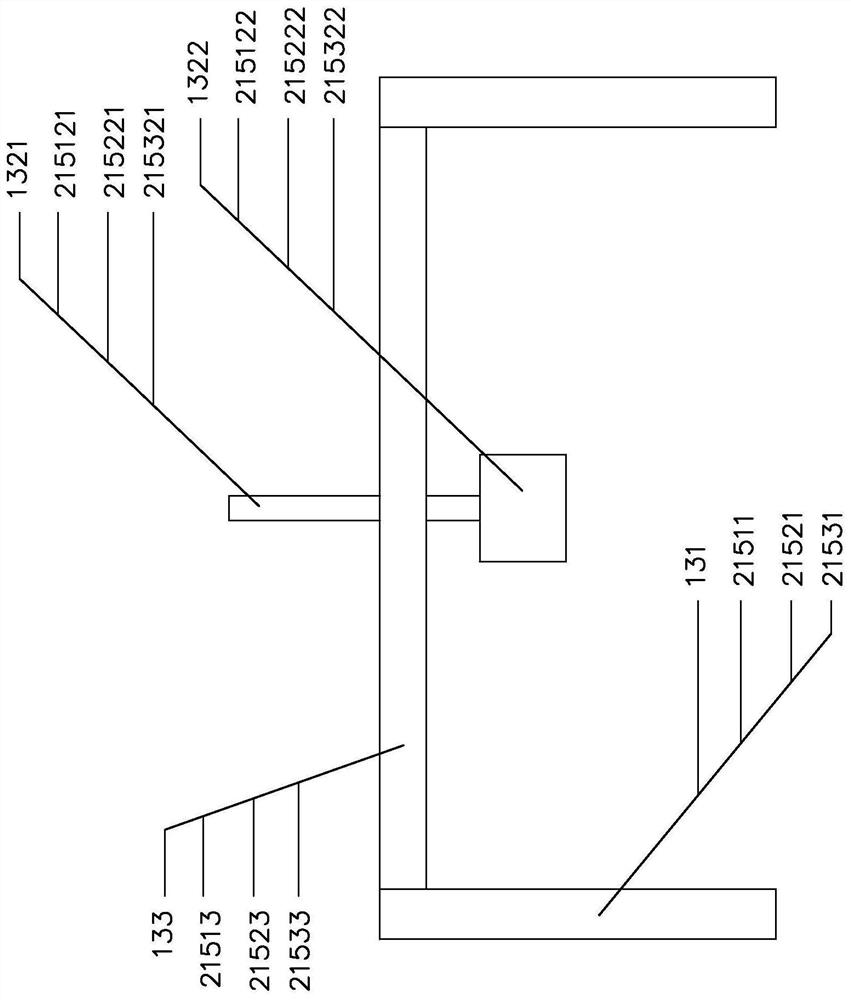

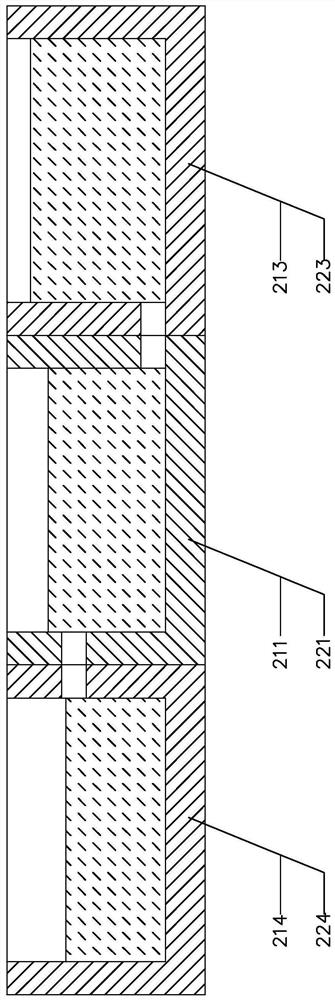

[0060] Preferably, the melting tin room includes a high-temperature floating room at the upstream and a low-temperature floating room at the downstream; The high-temperature house cover 212, the high-temperature supply tin tank 213 for supplying molten tin liquid to the high-temperature melting tin floating tank 211, and the high-temperature recovery tin tank 214 for containing the molten tin liquid flowing out from the high-temperature melting tin floating tank 211; The low-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com