Oil well cement resistant to strength retrogression at high temperature and production method thereof

A technology of oil well cement and strength, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of strength reduction, cement stone strength attenuation, and cement stone strength destruction, so as to achieve non-fading strength and high embankment compactness , the effect of delaying the time of hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

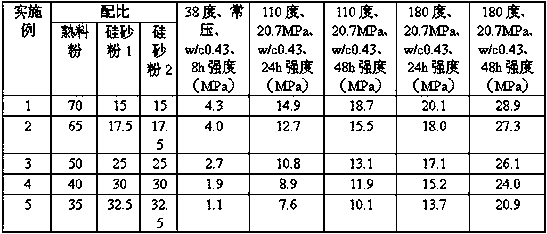

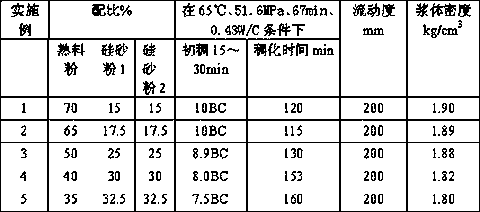

Embodiment 1

[0023] (1) Prepare oil well cement clinker according to conventional methods, and control the mineral composition of cement clinker to be C 3 S at 10~25%, C 2 S at 50~65%, C 3 A at 0~3%, C 4 AF at 12~15%;

[0024] (2) The oil well cement clinker, gypsum and retarder are put into the grinding together according to the ratio. The ratio is that the oil well cement clinker accounts for 95% of the mass, the gypsum accounts for 4% of the mass, and the retarder is 1%. The specific area of grinding is 150-220cm² / kg, 0.080mm sieve, 13-20%, SO 3 Clinker powder with a content of 1.5~3.0%;

[0025] (3) Separately grind the silica sand into two kinds of powders with different fineness, that is, silica sand powder 1 with a 0.045mm sieve residue of 4-6% and 0.045mm sieve residue with a 15-25% silica sand powder 2, and then step (2) The prepared clinker powder, silica sand powder 1, and silica sand powder 2 are mixed according to the mass percentage of cement clinker powder 70%, silica...

Embodiment 2

[0028] (1) Prepare oil well cement clinker according to conventional methods, and control the mineral composition of cement clinker to be C 3 S at 10~25%, C 2 S at 50~65%, C 3 A at 0~3%, C 4 AF at 12~15%;

[0029] (2) The oil well cement clinker, gypsum and retarder are put into the grinding together according to the proportion, the proportion is 95% of oil well cement clinker, 4% of gypsum and 1 / % of retarder, and the specific area of grinding is 150-220cm² / kg, 0.080mm sieve, 13-20%, SO 3 Clinker powder with a content of 1.5~3.0%;

[0030] (3) Separately grind the silica sand into two kinds of powders with different fineness, that is, silica sand powder 1 with a 0.045mm sieve residue of 4-6% and 0.045mm sieve residue with a 15-25% silica sand powder 2, and then step (2) The prepared clinker powder, silica sand powder 1, and silica sand powder 2 are mixed according to the mass percentage of cement clinker powder 65%, silica sand powder 1 17.5%, and silica sand powder 2 ...

Embodiment 3

[0033] (1) Prepare oil well cement clinker according to conventional methods, and control the mineral composition of cement clinker to be C 3 S at 10~25%, C 2 S at 50~65%, C 3 A at 0~3%, C 4 AF at 12~15%;

[0034] (2) The oil well cement clinker, gypsum and retarder are put into the grinding together according to the proportion, the proportion is 95% of oil well cement clinker, 4% of gypsum and 1 / % of retarder, and the specific area of grinding is 150-220cm² / kg, 0.080mm sieve, 13-20%, SO 3 Clinker powder with a content of 1.5~3.0%;

[0035] (3) Separately grind the silica sand into two kinds of powders with different fineness, that is, silica sand powder 1 with a 0.045mm sieve residue of 4-6% and 0.045mm sieve residue with a 15-25% silica sand powder 2, and then step (2) The prepared clinker powder, silica sand powder 1, and silica sand powder 2 are mixed according to the mass percentage of 50% of cement clinker powder, silica sand powder 1 25%, and silica sand powder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com