3D printing method for house

A 3D printing and 3D printer technology, applied in construction, building construction, additive processing, etc., can solve problems such as waste of building materials and energy, environmental pollution of construction projects, lag in management mode, etc., to improve construction efficiency and accuracy, The effect of reducing production costs and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

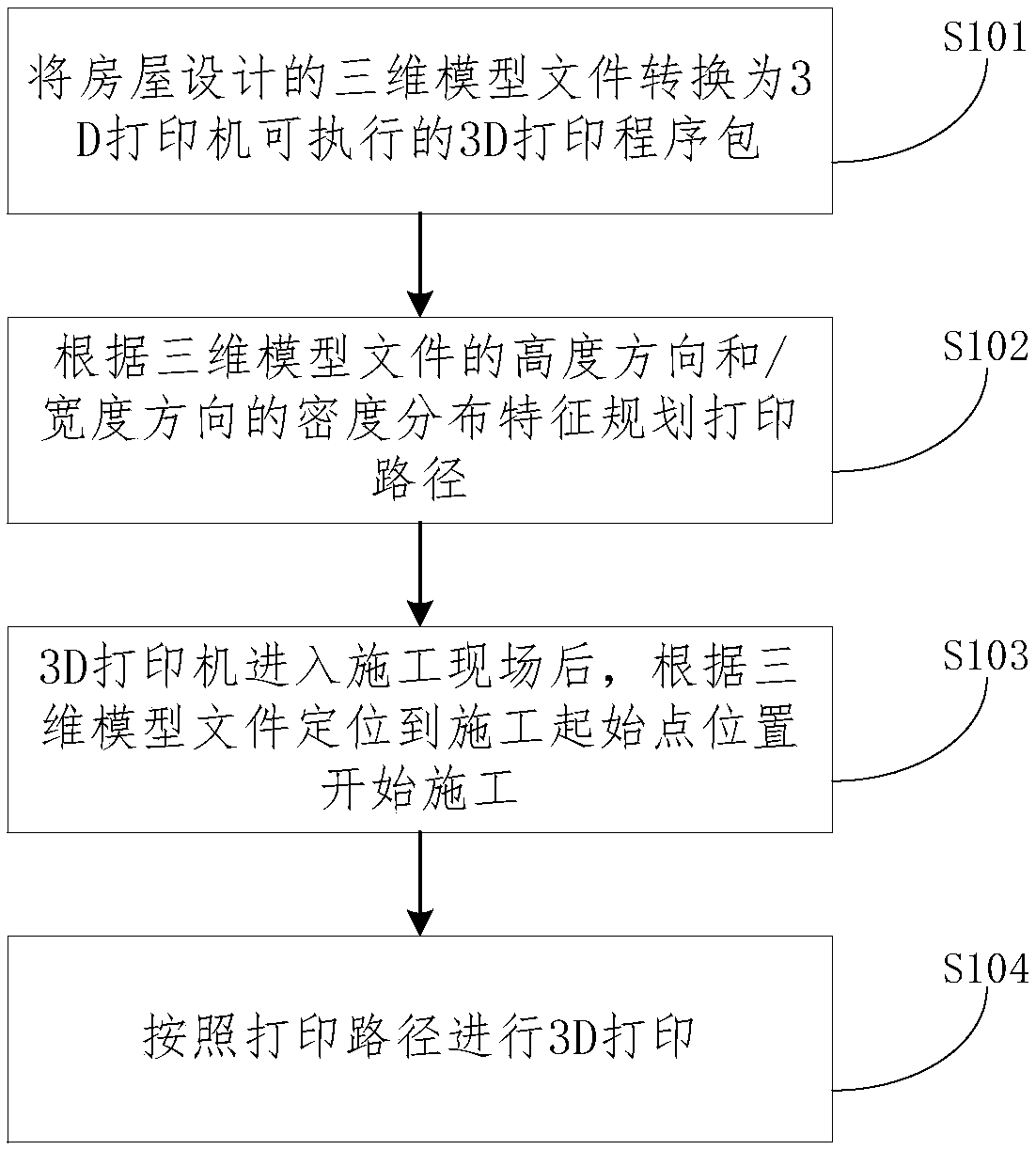

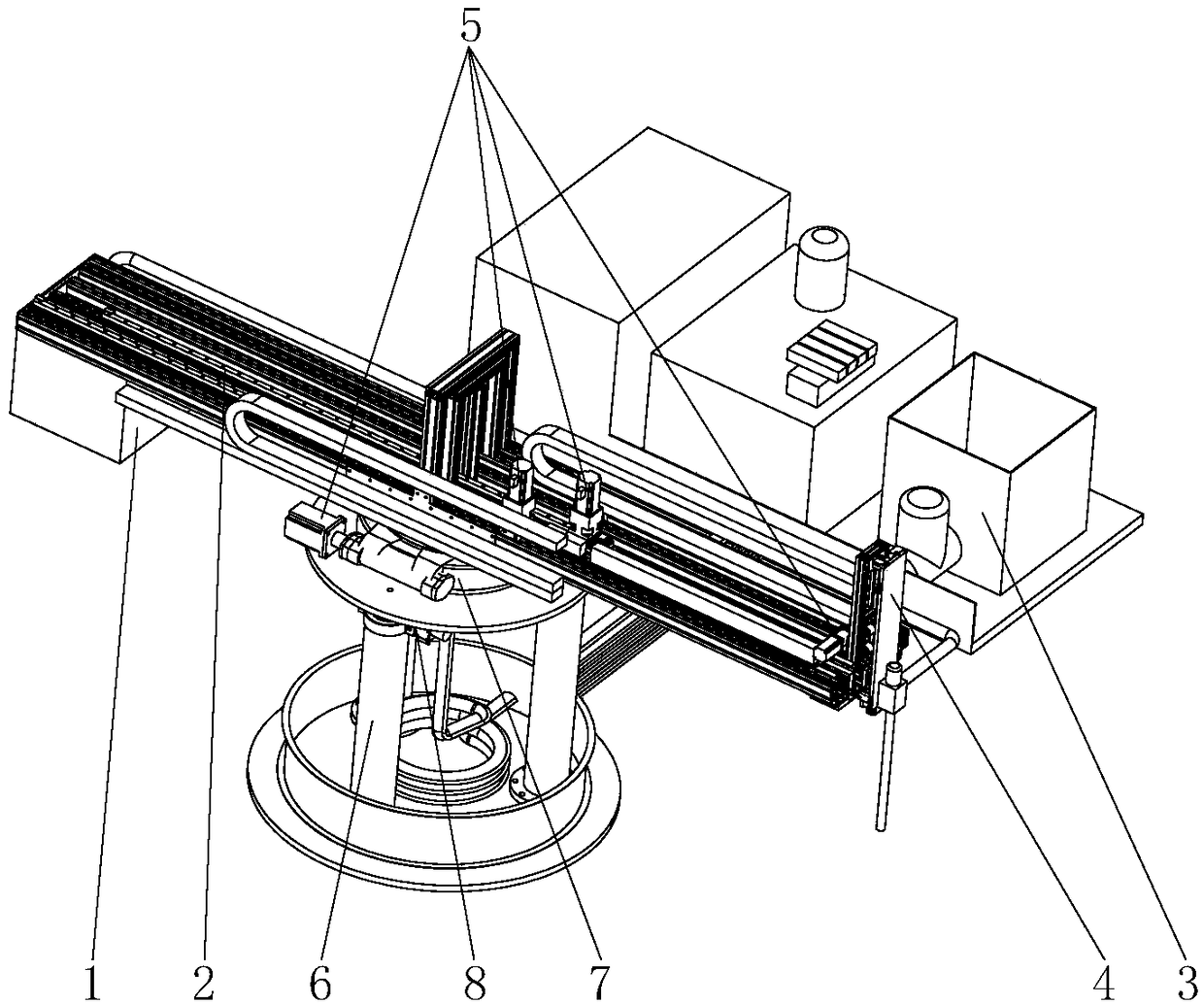

[0044] Such as Figure 1 to Figure 4 As shown, the 3D printing method of a house provided in this embodiment includes the following steps:

[0045] Step 1 S101, converting the 3D model file of the housing design into a 3D printing program package executable by the 3D printer;

[0046] Step 2 S102, planning the printing path according to the density distribution characteristics of the height direction and / or width direction of the 3D model file;

[0047] Step 3 S103, after the 3D printer enters the construction site, locate the construction starting point according to the 3D model file and start construction;

[0048] Step 4 S104, perform 3D printing according to the printing path.

[0049]The 3D printing method of the house includes the following steps: Step 1 S101, converting the 3D model file of the house design into a 3D printing program package executable by the 3D printer, and Step 2 S102, according to the density of the 3D model file in the height direction and / or widt...

Embodiment 2

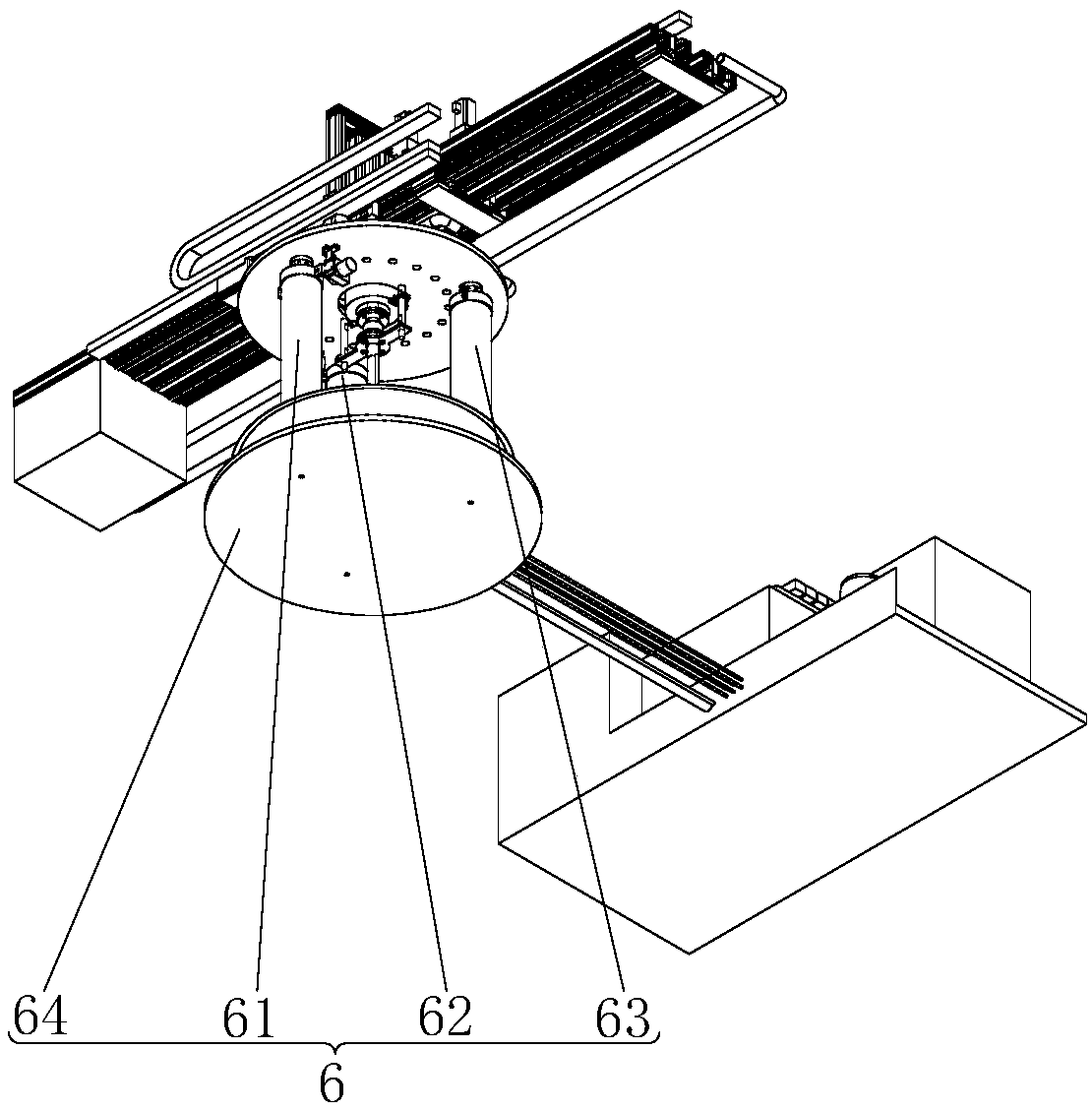

[0095] Different from Embodiment 1, the lifting component 6 adopts a tower crane.

[0096] Further, the number of tower cranes may be one, which is set at the center of the base 64 and connected with the center of the rotating assembly 7 .

[0097] Further, there may be multiple tower cranes, which are evenly spaced in the base 64 and connected with the rotating assembly 7 .

[0098] In this embodiment, a tower crane is used as the lifting component 6 of the device, which can complete the construction of houses with higher height requirements.

Embodiment 3

[0100] The present invention also provides a house construction system, including the 3D printers in any one of the above embodiments, where there are multiple 3D printers, and the overall console controls the work distribution and coordination between the multiple 3D printers.

[0101] In this embodiment, different types of houses, such as villas, bungalows, high-rises, etc., have different requirements for the height and width of the house. Therefore, a house construction system is provided, including a plurality of 3D house printers, according to each 3D printer The working scope of the house is divided into areas, so that different 3D printers are responsible for different areas, and multiple areas are spliced to complete the construction of the house, so that the device is no longer limited to a certain type of house construction, and the mechanized construction of construction projects is improved. level and efficiency, reducing building material and energy consumption....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com