Large-span single-piece hollowed-out shaping terracotta brick wall and construction method thereof

A large-span, clay technology, applied in the direction of walls, building structures, building components, etc., can solve the problem that the fixing method is not suitable for walls with special shapes, etc., so as to save maintenance costs in the later period, moderate construction costs, and good lateral rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

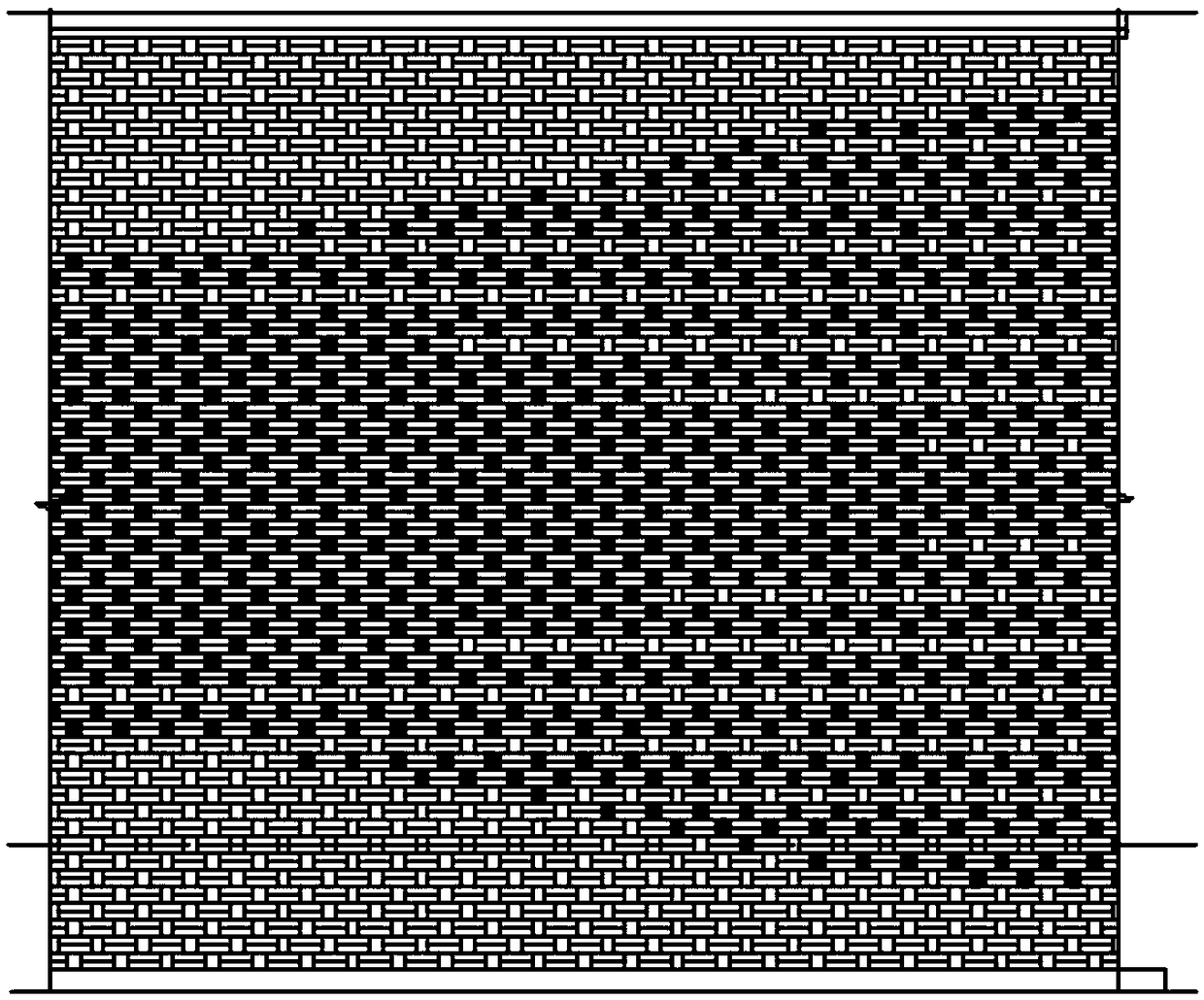

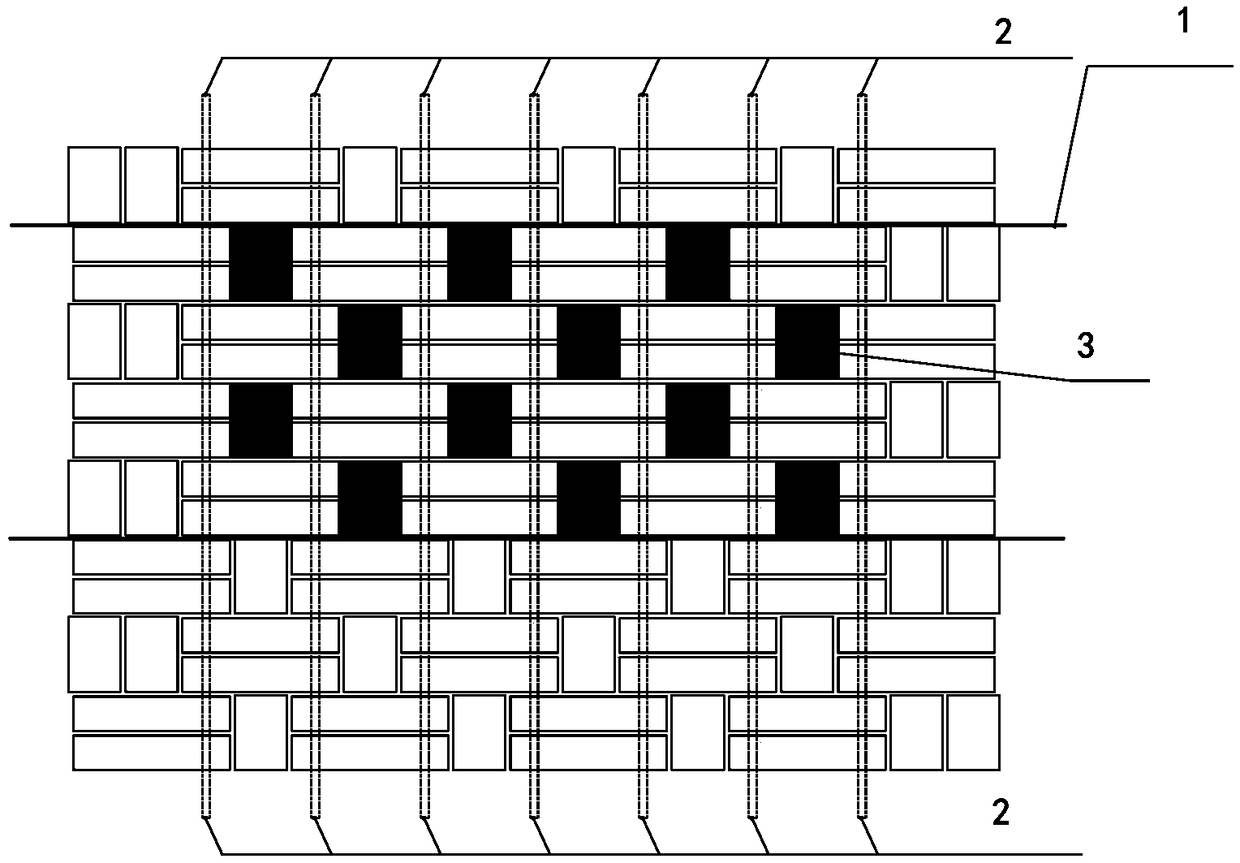

[0028] Combine below figure 1 and figure 2 Describe in detail the structural composition of the large-span single-piece hollow-shaped clay brick wall of the present invention.

[0029] Please refer to figure 1 and figure 2 , a large-span single-piece hollow-shaped clay brick wall, which includes a number of clay bricks (not shown) that are built according to the arrangement of vertical staggered joints and horizontal joints, and are passed through horizontal steel strips 1 and vertical steel bars 2 And the overall space grid formed by structural columns (not shown) is fixed; the clay bricks are hollow bricks, holes are opened along the thickness direction of the clay bricks, and a horizontal steel belt 1 is arranged at regular intervals on the clay brick wall, and the horizontal steel belt 1 is set on The horizontal joints are the connecting joints between vertically adjacent clay bricks. The two ends of the horizontal steel belt 1 are respectively fixedly connected by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com