Operation platform and continuous operation system and operation method for tunnel construction thereof

A work platform and tunnel construction technology, which is applied in tunnels, tunnel linings, earthwork drilling, etc., to achieve the effect of overcoming the diversity of excavation methods and the irregularity of the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

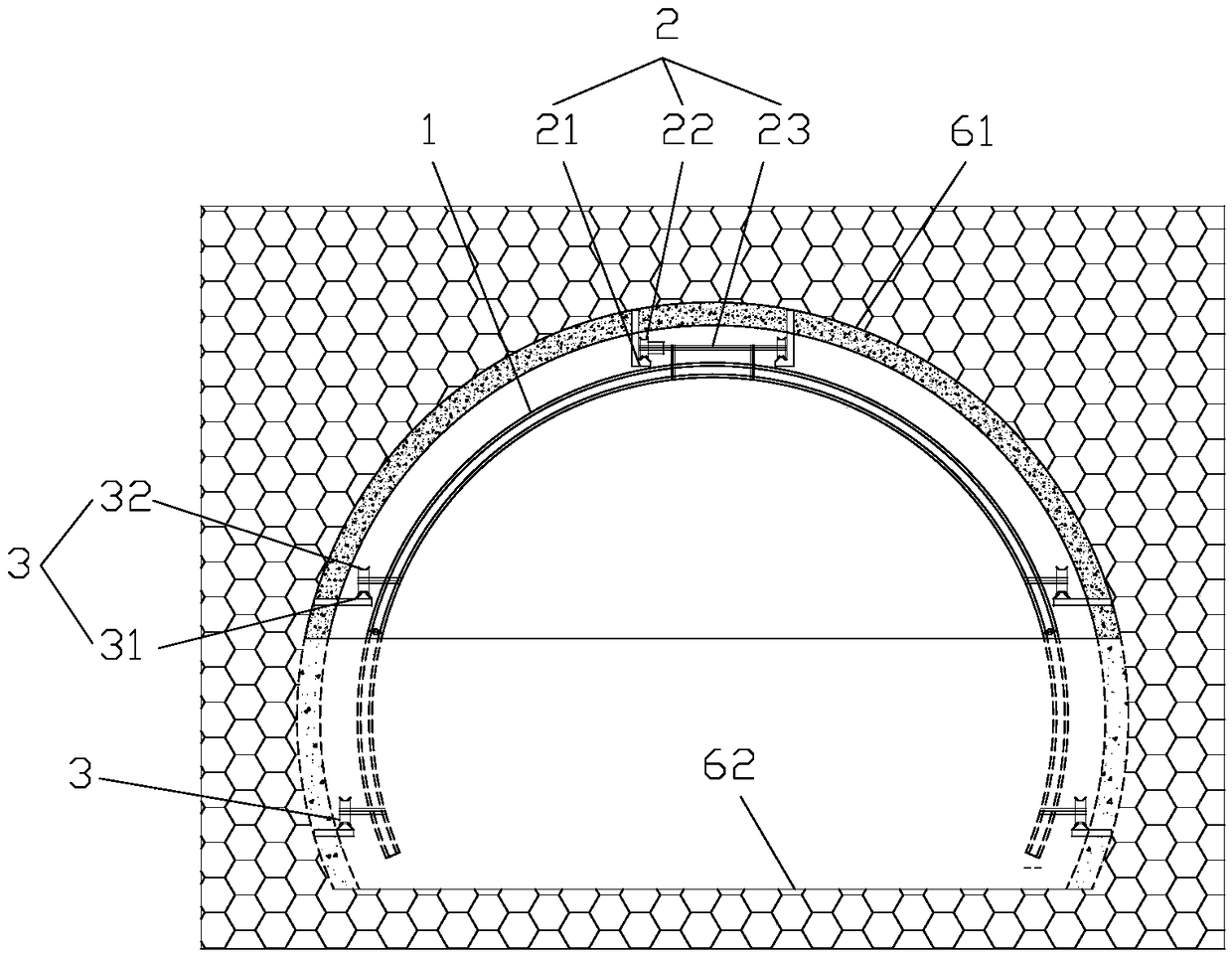

[0045] In order to solve the problem that trolleys and other operating equipment are not easy to erect and move due to the irregular construction site during the construction process of tunnel drilling and blasting, a new type of operating platform is provided, as shown in the attached figure 1 As shown, the working platform mainly includes an arch support 1 , a main traveling mechanism 2 and an auxiliary traveling mechanism 3 .

[0046] Specifically, the arched support 1 is an arc-shaped truss member, and its outer arc shape is similar to the shape of the tunnel arched inner wall 61, which can ensure that the entire arched support 1 is close to the tunnel arched inner wall. The top of the platform is parallel to the cross-section of the arched inner wall of the tunnel, so that when the entire work platform is moving, it can avoid collision with the arched inner wall of the tunnel.

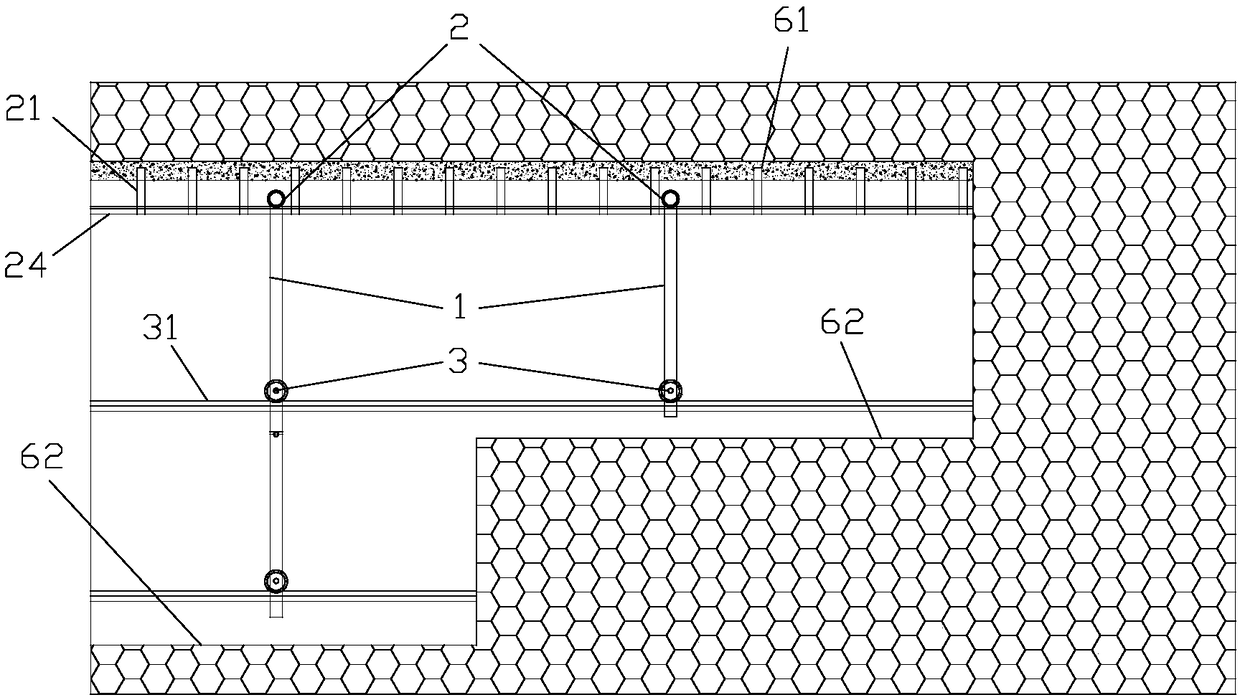

[0047] combine figure 2 As shown, in different construction sections inside the tunnel, the ...

Embodiment 2

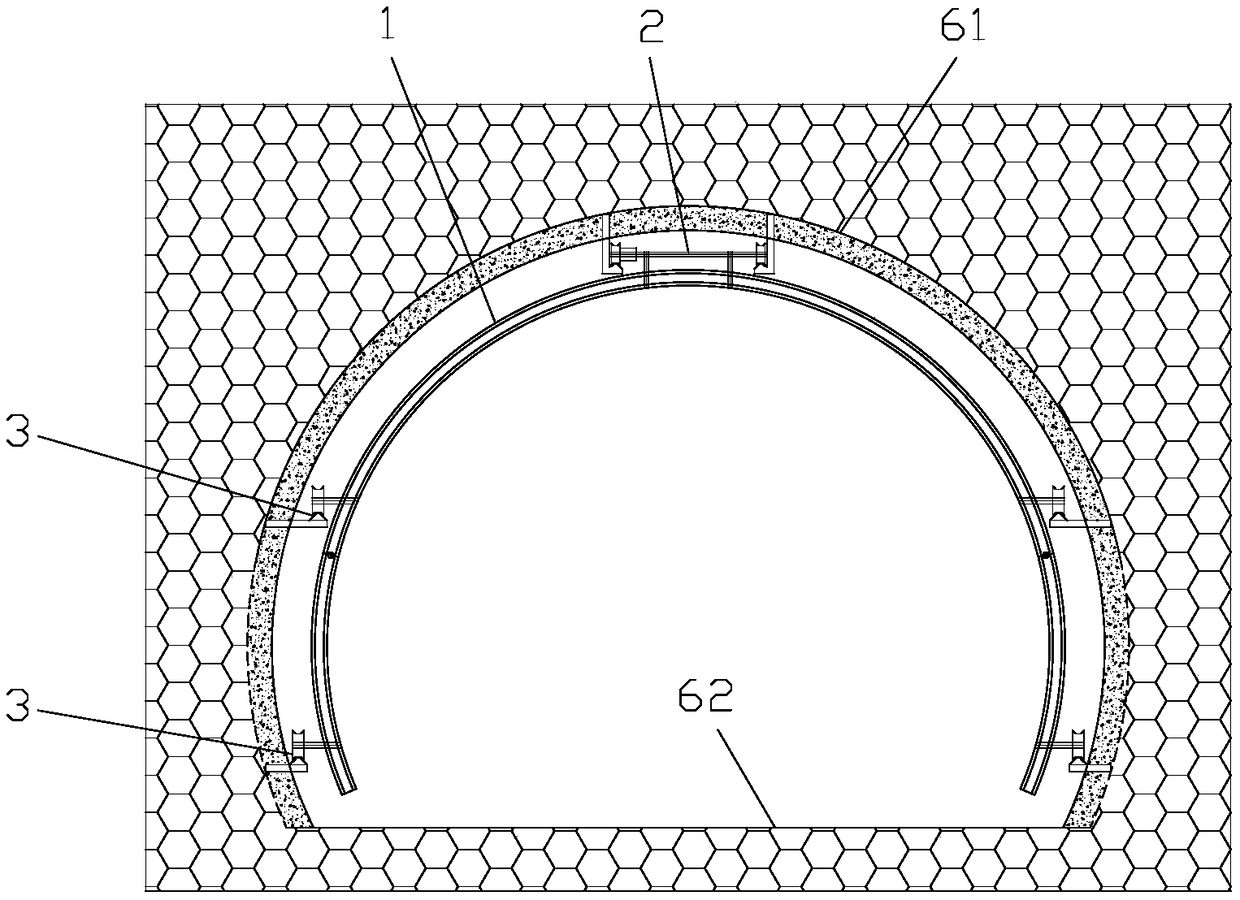

[0059] Embodiment 1 belongs to a light-duty work platform, which can be used in construction procedures that do not need to bear a large load, such as scanning the inner wall of a tunnel. In order to further improve other construction procedures that need to bear relatively large loads, this embodiment provides another working platform solution on the basis of the first embodiment.

[0060] Specific as Figure 6 As shown, while the arched support 1 is suspended and connected to the tunnel arched inner wall 61 through the main traveling mechanism 2 and the auxiliary traveling mechanism 3, in order to realize the construction process that the arched support 1 can bear a greater load, the arched support 1 is also An auxiliary support system 5 is set up. After the arch support 1 is moved to a fixed position, the support between the arch support 1 and the tunnel arch inner wall 61 and the tunnel floor 62 is formed to provide auxiliary support for the working platform during constru...

Embodiment 3

[0066] This embodiment provides a continuous operation system for tunnel construction based on Embodiment 1 and Embodiment 2, specifically as Figure 7 , Figure 8 and Figure 9 As shown, it includes multiple sets of working platforms on the upper and lower steps inside the tunnel. The working platforms in different construction sections are equipped with corresponding construction equipment heads to carry out construction on the inner wall of the tunnel corresponding to the construction section. After a construction section is completed, the The working platform in the following construction section moves forward through the traveling mechanism to realize continuous construction operations in the tunnel.

[0067] The following combination Figure 8 and Figure 9 Describe in detail.

[0068] Such as Figure 8 As shown, three sets of hoop traveling mechanisms 4 are arranged on the arched support 1 of the working platform in the figure, and each set of hoop traveling mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com