Connecting and mounting structure of diesel engine and matched TPR61 supercharger

A technology of installation structure and supercharger, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as inability to convert, high exhaust temperature of real ships, and small design margin of VTC304 supercharger, so as to improve the environment Adaptability, the effect of simplifying the installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

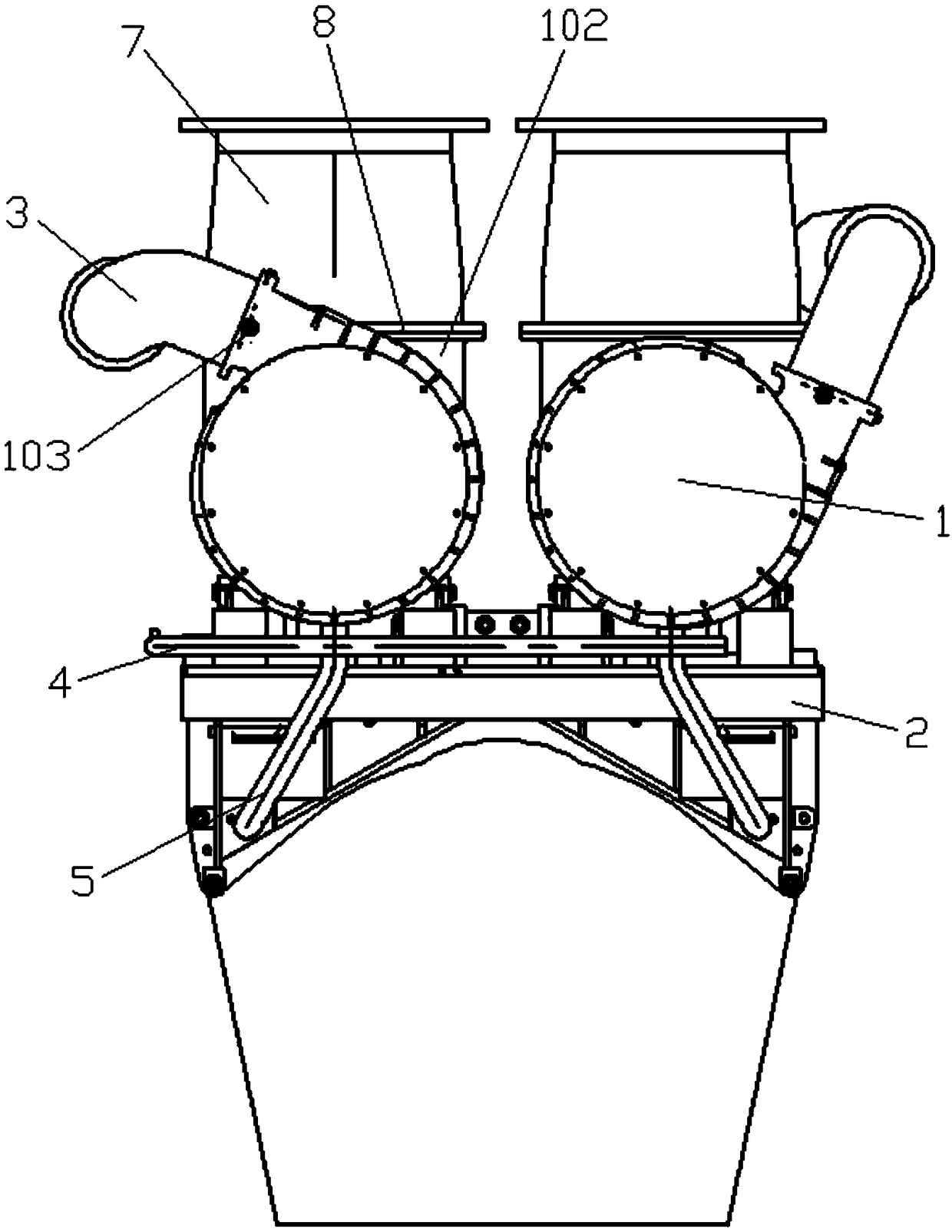

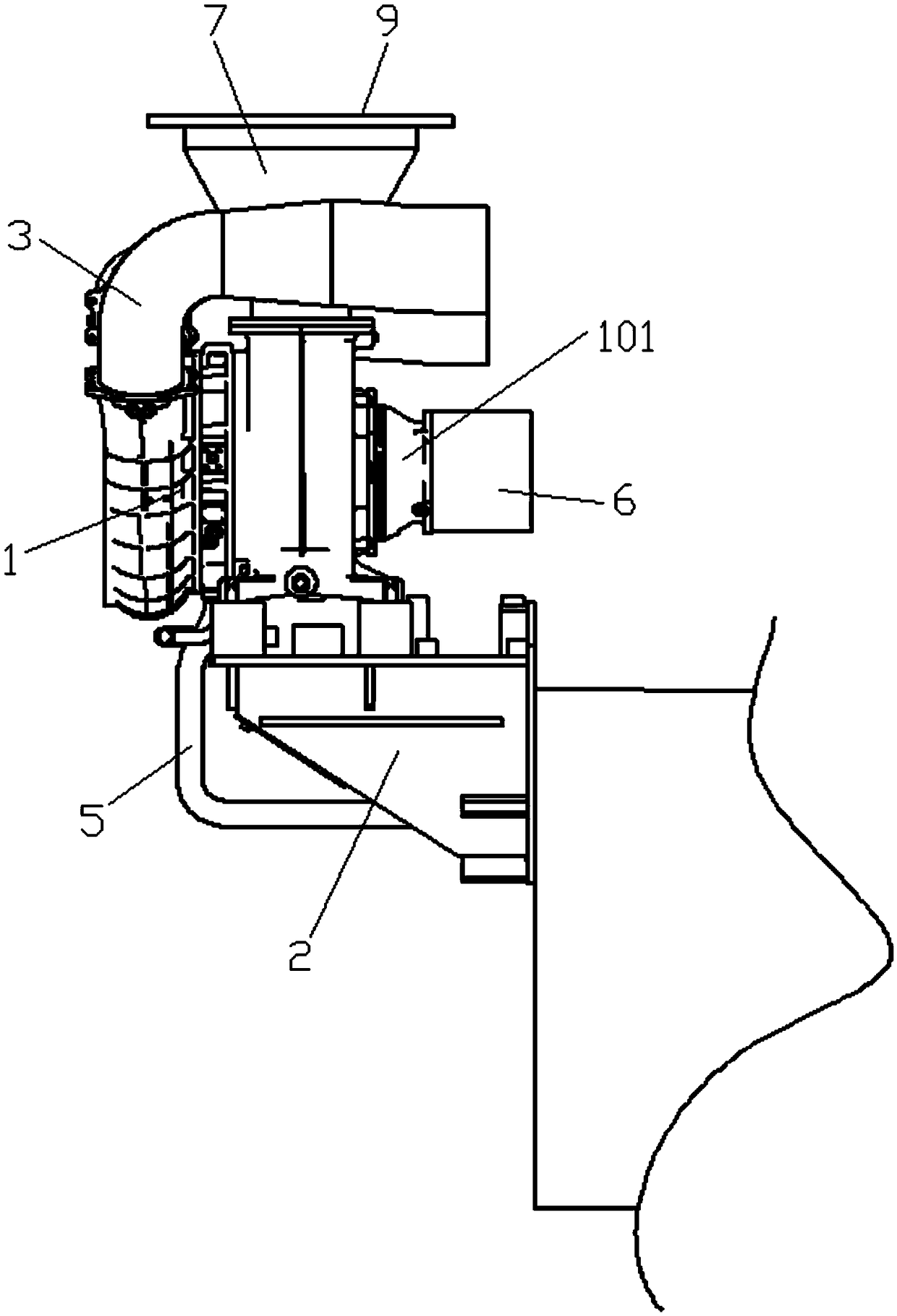

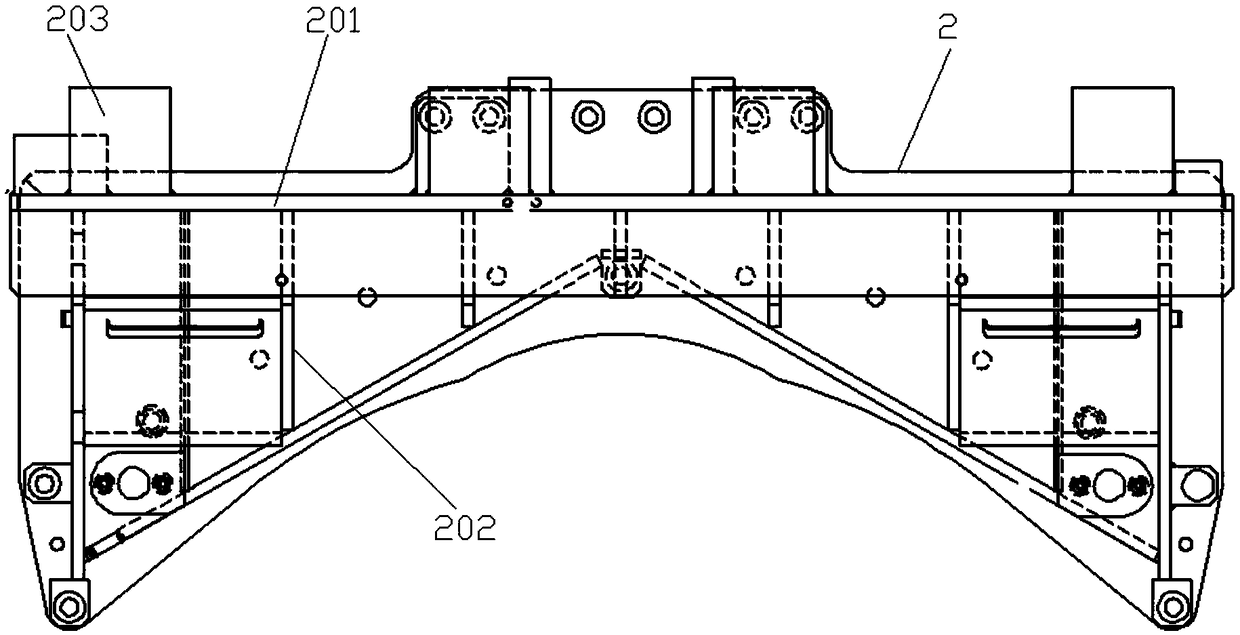

[0025] The following will be combined with Figure 1-11 The technical solution of the present invention is clearly and completely described.

[0026] The connection pipeline structure of a diesel engine matching a TPR61 supercharger, the present invention is a design work carried out for a 16PA6V-280STC diesel engine matching a TPR61 supercharger. TPR61-F33 supercharger is a substitute product of ABB’s VTC304 supercharger. The advantages of choosing TPR61 supercharger are as follows:

[0027] 1. Compared with the VTC304 supercharger, the TPR61 turbocharger has the following technical features: 1) Integral turbine shaft disk, which improves the low shaft fatigue characteristics and life; 2) The exhaust gas turbine housing integrates the foot design, which enhances reliability; 3) The service life of the supercharger bearing has been increased from 24,000 hours to 36,000 hours, and the reliability index has been significantly improved; 4) The recirculation design of the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com