Full-automatic efficient natural gas burner

A burner and natural gas technology, applied in the direction of gas fuel burners, burners, burners, etc., can solve the problems of not being able to guarantee the high efficiency of the heating system, insufficient anti-back pressure ability, and large gas consumption, so as to ensure efficient operation , saving consumption, ensuring safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

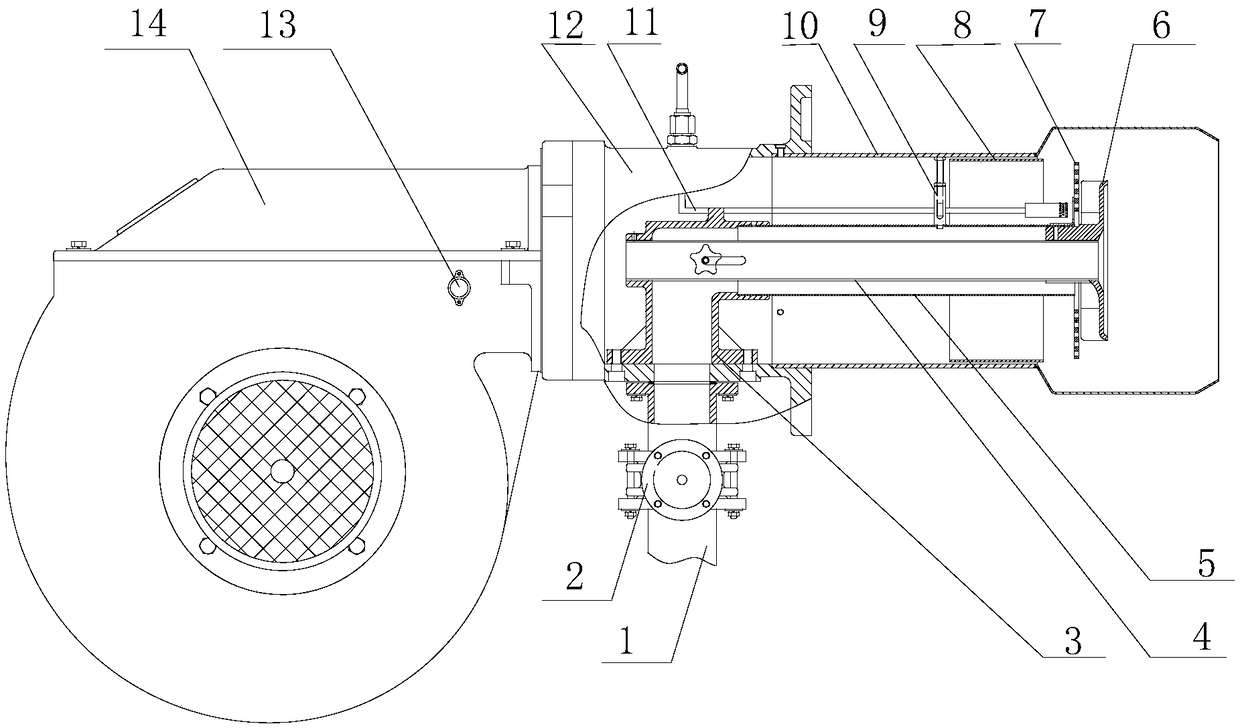

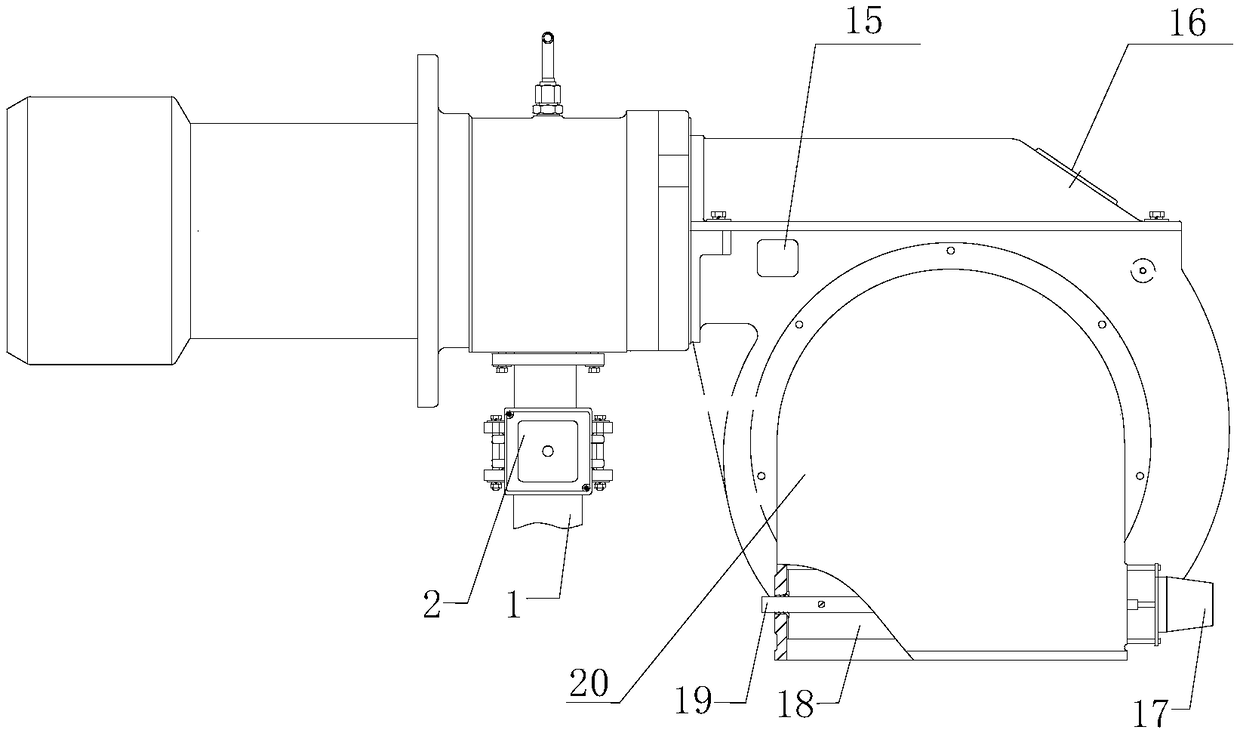

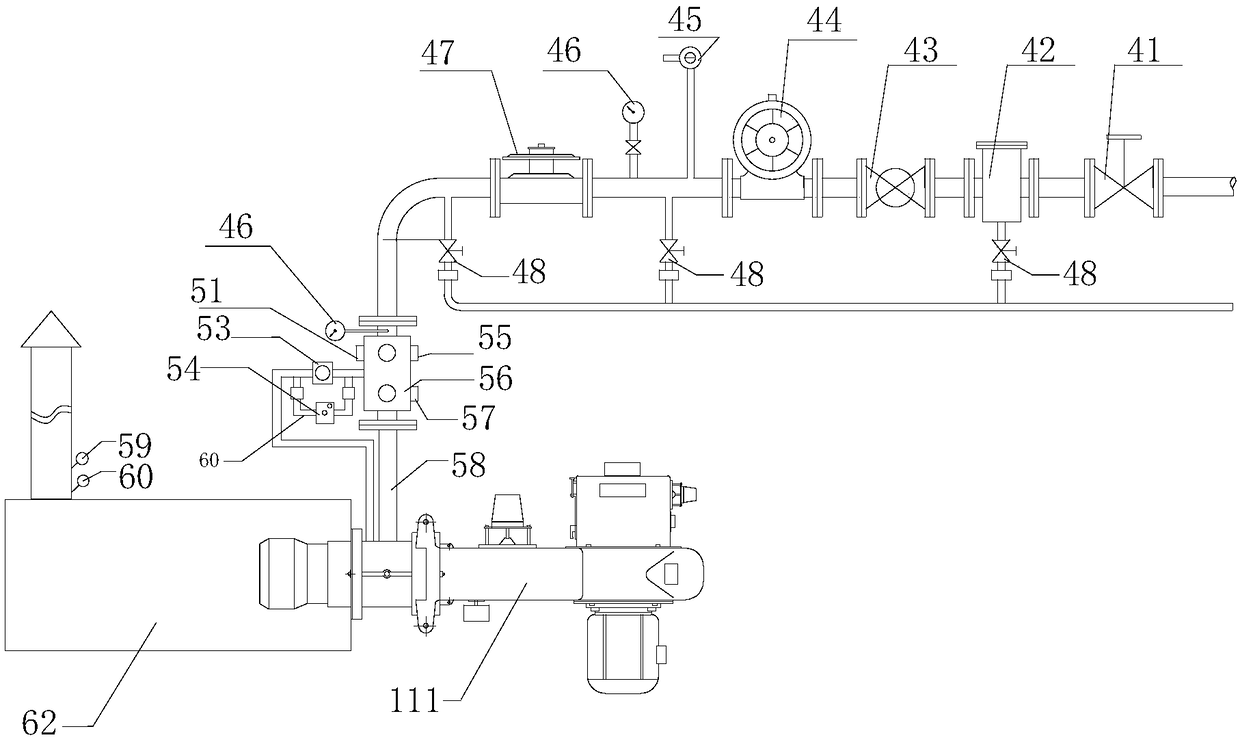

[0020] Attached below figure 1 , figure 2 , image 3 and Figure 4 For the embodiments of the present invention, the present invention is further described:

[0021] Such as figure 1 , image 3 and image 3 as shown in:

[0022] In this embodiment, the present invention includes a burner body 111, a flue gas temperature sensor 59 arranged on the burner chimney, a flue gas oxygen content sensor 60, and a gas control system and an ignition control system for realizing burner work flow control. system and gas trim system. During specific implementation, the gas control system, ignition control system and gas fine-tuning system can all realize nearby or remote real-time control through the local control box 222 and the remote centralized display control device 333, such as Figure 4 shown in .

[0023] The burner body 111 includes an air supply device, an air supply device and an ignition device; the air supply device includes a blower fan 14, an external air cylinder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com