A Measuring Method of Fatigue Crack Growth Rate Based on Infrared Thermal Imaging Technology

A technology for fatigue crack growth and fatigue cracks, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of increased test cost, non-reusable use, and high consumption of fracture pieces, and achieve low test environment requirements and reduce Human error, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

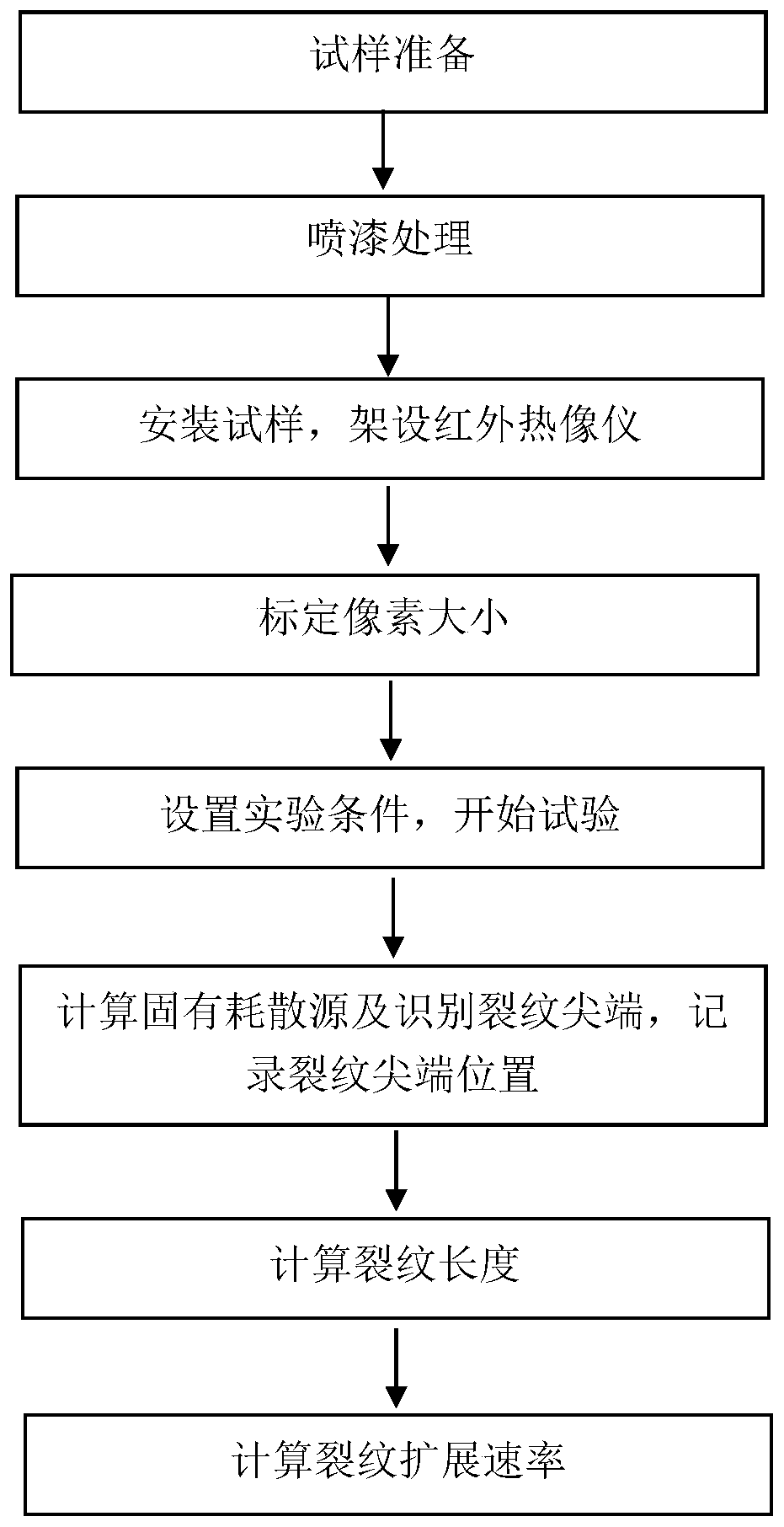

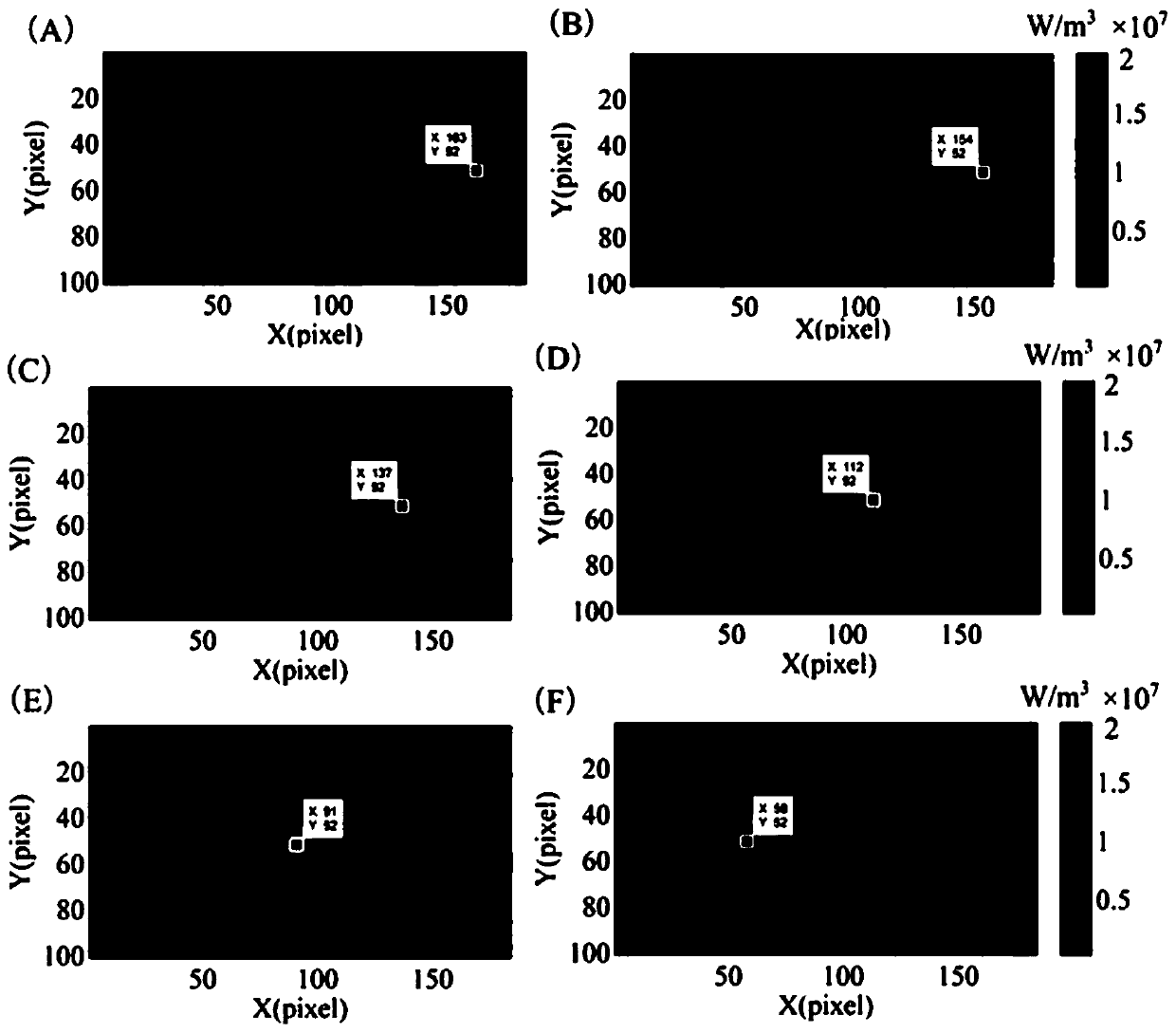

[0042] Below in conjunction with the operation flow chart, the specific implementation is described in detail as follows:

[0043] Sample preparation, painting treatment. The sample is machined to achieve the required geometry and surface roughness. Spray a thin and uniform layer of black matt paint on the surface of the sample to increase the thermal emissivity of the sample and ensure the uniform distribution of the surface emissivity.

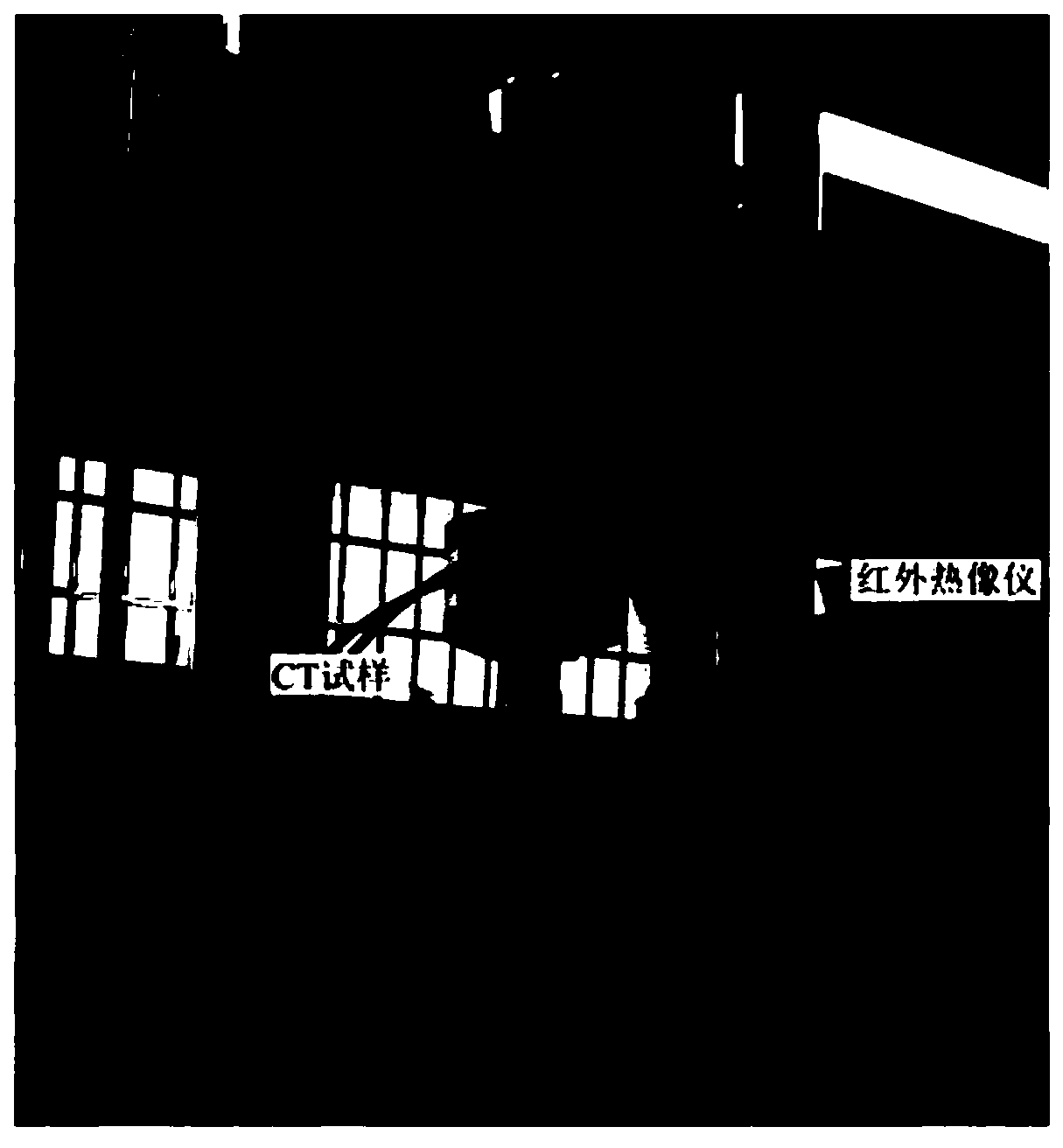

[0044] Install the sample and set up the infrared thermal imager. Before the experiment, try to ensure that the external environment is at a constant temperature, such as using an air conditioner for temperature control, so as to avoid the influence and interference of the ambient temperature fluctuation on the temperature field of the sample surface. Install the sample with a suitable fixture, set up the infrared thermal imager to a suitable position, adjust the focal length of the lens until the fatigue crack outline can be clearly obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com