An antibacterial food freshness indicator material capable of detecting carbon dioxide and its preparation method

A carbon dioxide and freshness technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, material analysis, material analysis by optical means, etc. It is applied in the field of food packaging, which is difficult to promote, etc., to achieve the effect of extending its shelf life, inhibiting the growth of harmful bacteria, and having good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing an antibacterial food freshness indicating material capable of detecting carbon dioxide, comprising the following steps:

[0054] Step 1. According to parts by weight, 2-6 parts of starch, 0.1-0.5 parts of titanium dioxide dispersion, 1-5 parts of calcium hydroxide, 1-4 parts of glycerol, 1-3 parts of urea, and 0.05 parts of xanthan gum -0.2 parts, 80-90 parts of water, after mixing, stirring and ultrasonic treatment, heating at 70-90°C to obtain film solution A;

[0055] Step 2. According to parts by weight, mix 3-8 parts of polyvinyl alcohol and 85-95 parts of water, stir after mixing, and heat at 80-100°C to obtain film solution B;

[0056] Step 3, according to parts by weight, 1-3 parts of methyl red solution with a concentration of 0.05%-0.25%, 2-6 parts of bromothymol blue solution with a concentration of 0.1%-0.25%, the two are according to the ratio of parts After mixing 1:2~2.5, carry out stirring and ...

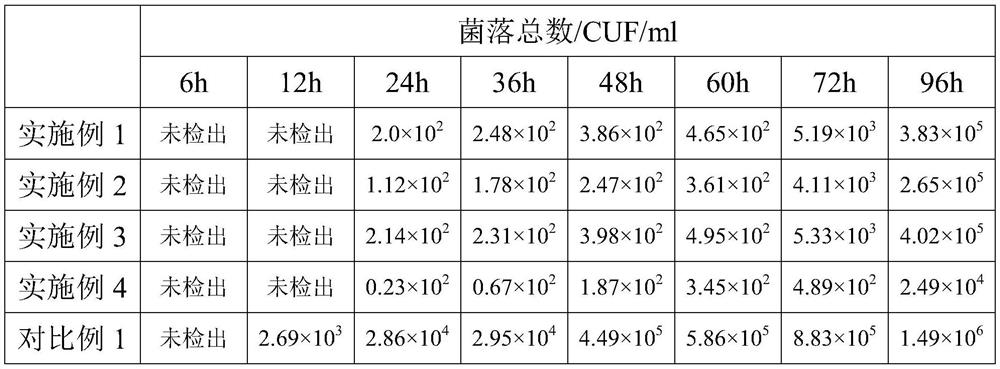

Embodiment 1

[0064] In this embodiment, the antibacterial food freshness indicating material capable of detecting carbon dioxide is composed of the following raw materials:

[0065] Membrane solution A: 2 parts of starch, 0.1 part of titanium dioxide dispersion, 1 part of calcium hydroxide, 1 part of glycerol, 1 part of urea, 0.05 parts of xanthan gum, 80 parts of water; Membrane solution B: 3 parts of polyvinyl alcohol solution ; Membrane solution C: 1 part of methyl red solution with a concentration of 0.05%, and 2 parts of bromothymol blue solution with a concentration of 0.1%.

[0066] The preparation method includes as follows:

[0067] Step 1. According to parts by weight, mix 2 parts of starch, 0.1 part of titanium dioxide dispersion, 1 part of calcium hydroxide, 1 part of glycerol, 1 part of urea, 0.05 part of xanthan gum, and 80 parts of water, mix and stir and ultrasonic treatment, heated at 70°C to obtain membrane solution A;

[0068] Step 2. According to parts by weight, mix ...

Embodiment 2

[0072] In this embodiment, the antibacterial food freshness indicating material capable of detecting carbon dioxide is composed of the following raw materials:

[0073] Membrane solution A: 4 parts of starch, 0.3 parts of titanium dioxide dispersion, 3 parts of calcium hydroxide, 2 parts of glycerin, 2 parts of urea, 0.12 parts of xanthan gum, 85 parts of water; Membrane solution B: 6 parts of polyvinyl alcohol solution Membrane solution C: 2 parts of methyl red solution with a concentration of 0.09%, and 4.6 parts of bromothymol blue solution with a concentration of 0.18%.

[0074] The preparation method is as follows:

[0075] Step 1. According to parts by weight, mix 4 parts of starch, 0.3 parts of titanium dioxide dispersion, 3 parts of calcium hydroxide, 2 parts of glycerol, 2 parts of urea, 0.12 parts of xanthan gum, and 85 parts of water, mix and stir and ultrasonic treatment, heated at 80°C to obtain membrane solution A;

[0076] Step 2. According to parts by weight,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com