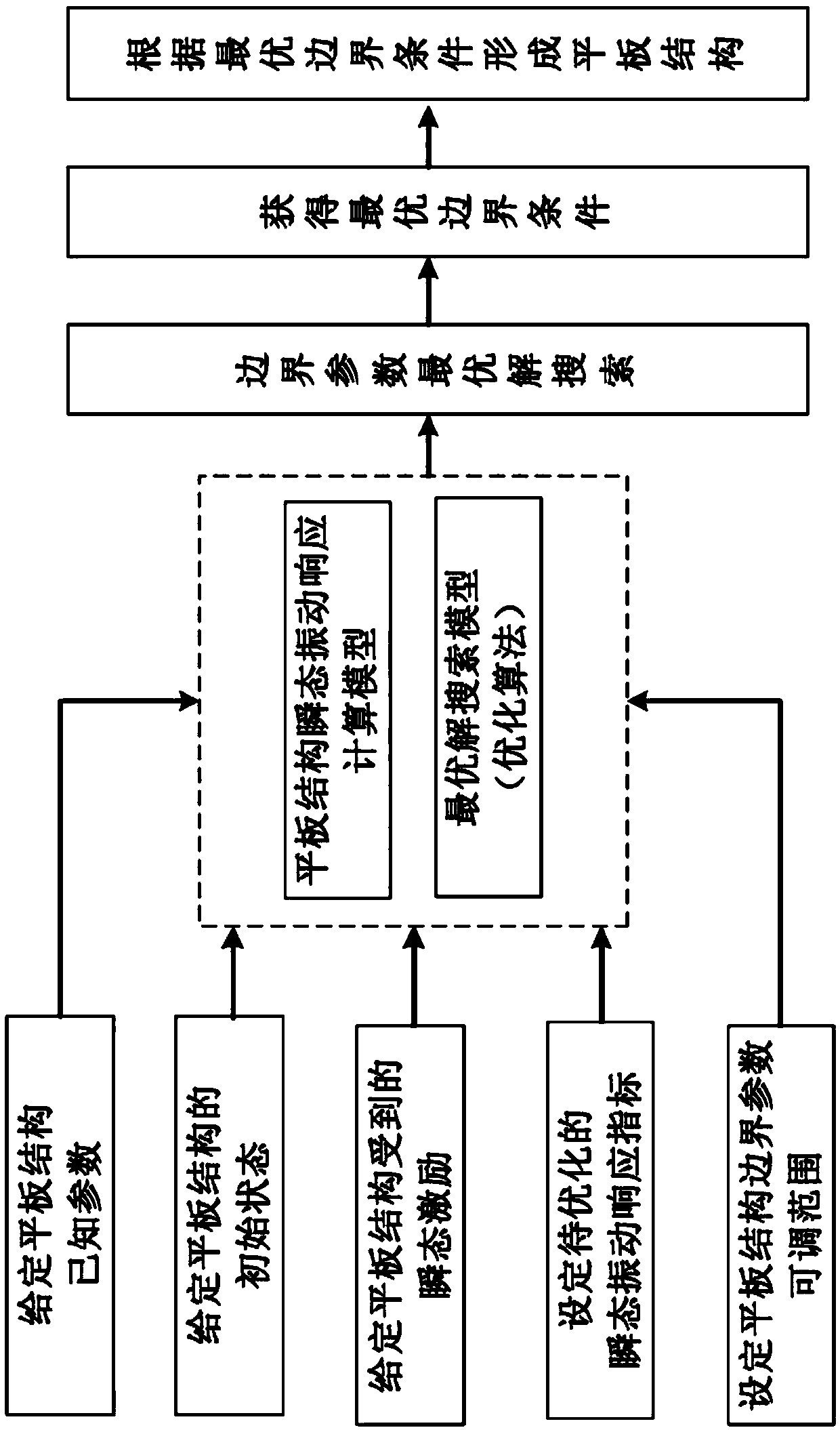

Optimum flat plate structure design method for improving transient vibration isolation performance

A technology for optimized design and transient vibration, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as multi-parameter parallel optimization, and achieve the effect of improving transient vibration isolation performance and improving vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The specific steps of the method for optimizing the design of a plate structure for improving transient vibration isolation performance in this embodiment are as follows:

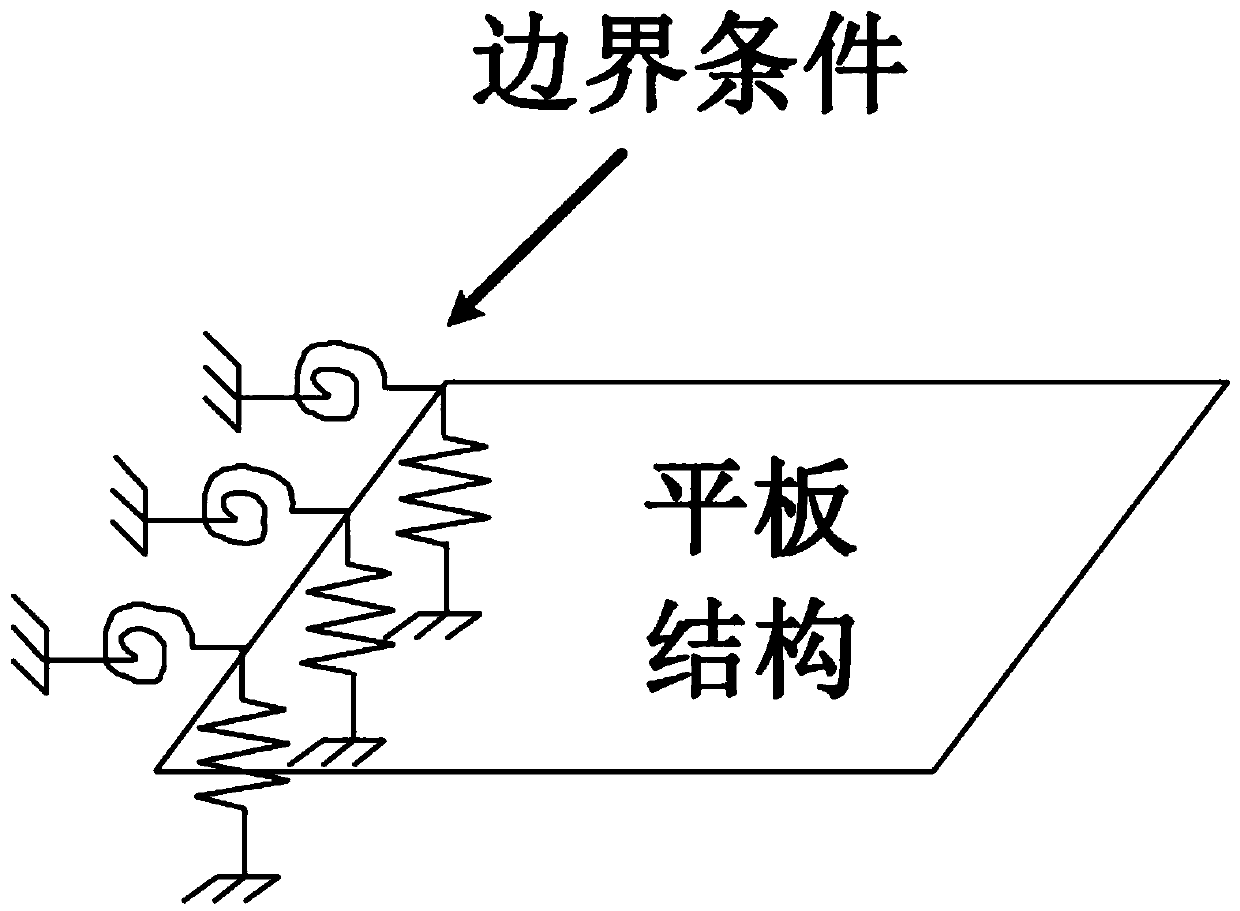

[0034] Step 1. Establish a calculation model for the transient vibration response of a flat plate structure applicable to any boundary conditions:

[0035]

[0036] in, and {δ(t)} are the instantaneous nodal acceleration, instantaneous nodal velocity and instantaneous nodal displacement vector of the plate structure at time t, respectively, Δt is the calculation time step, and {F(t)} is the instantaneous The excitation vector, α and γ are the time integration constants of Newmark method, respectively, and {M}, {C} and {K} are the overall mass matrix, damping matrix and overall stiffness matrix of the flat plate structure, respectively.

[0037] {M} and {K} can be obtained by the finite element method, that is, {M} is obtained by the equivalent mass matrix {M p} e Assembled by the direct stiffn...

Embodiment 2

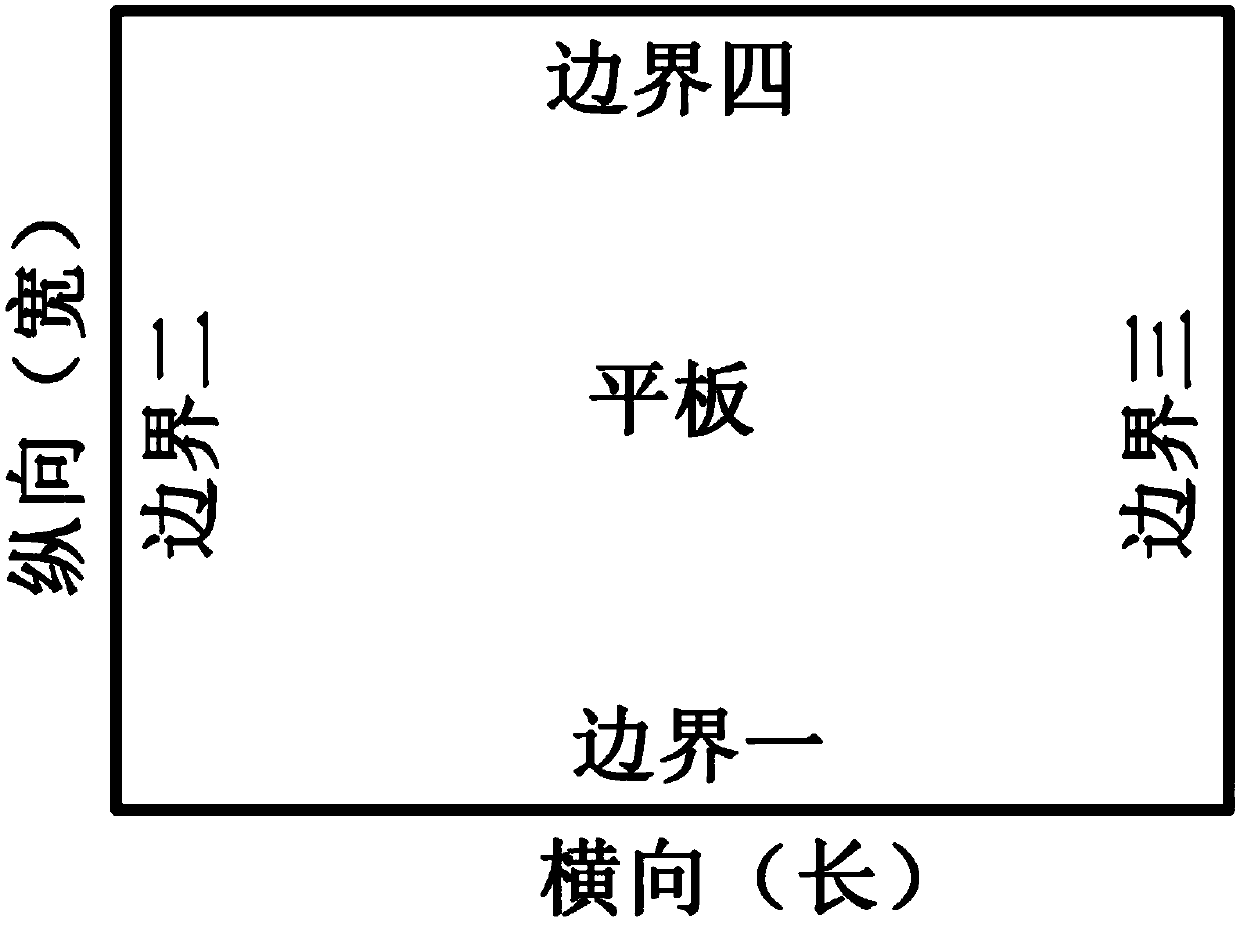

[0083] The method for optimizing the design of a plate structure for improving transient vibration isolation performance in this embodiment, the specific steps are as follows:

[0084]Step 1. Establish a calculation model of the transient vibration response of the flat plate structure applicable to any boundary conditions. The model is the same as that in Embodiment 1, and will not be repeated here.

[0085] Step 2. Set various known parameters of the plate structure: including plate material, damping factor, size, and thickness. The specific parameter values in this example are shown in the table below:

[0086]

[0087] Table 4

[0088] Step 3. Set the adjustable range of boundary parameters, as shown in the table below:

[0089]

[0090] table 5

[0091] Step 4. The initial state of the plate structure and the transient excitation received are given. The initial state given in this example is The center of the plate is subjected to a transient excitation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com