High-voltage bushing and high-voltage electrical equipment of using same

A technology for high-voltage bushings and high-voltage electrical appliances, applied in the fields of high-voltage electrical equipment and high-voltage bushings, can solve problems such as flashover safety risks, and achieve the effects of improving safety levels, ensuring insulation capacity, and avoiding flashovers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

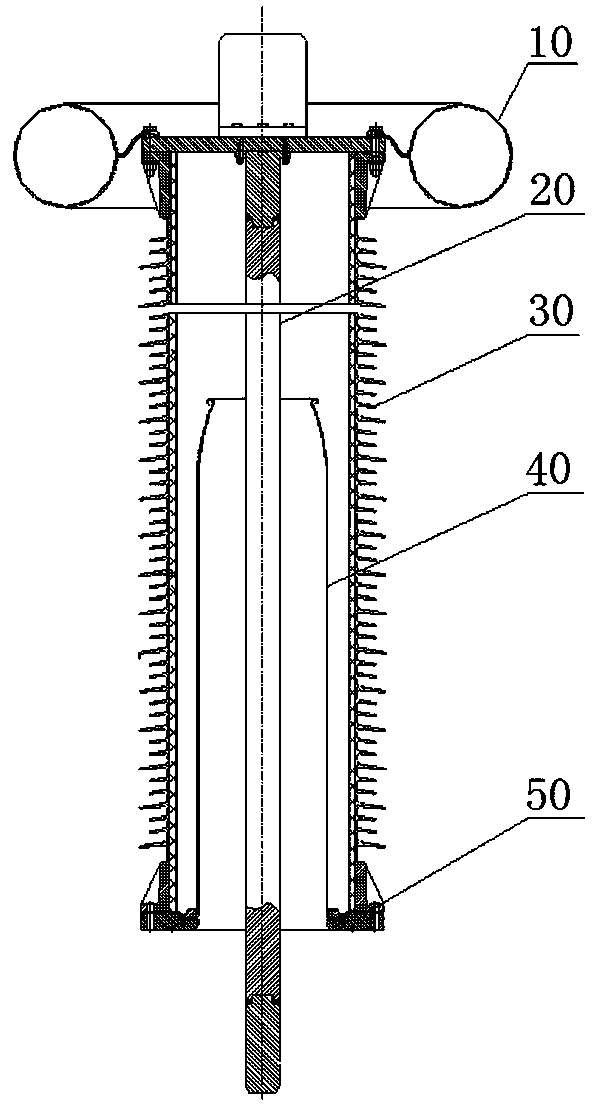

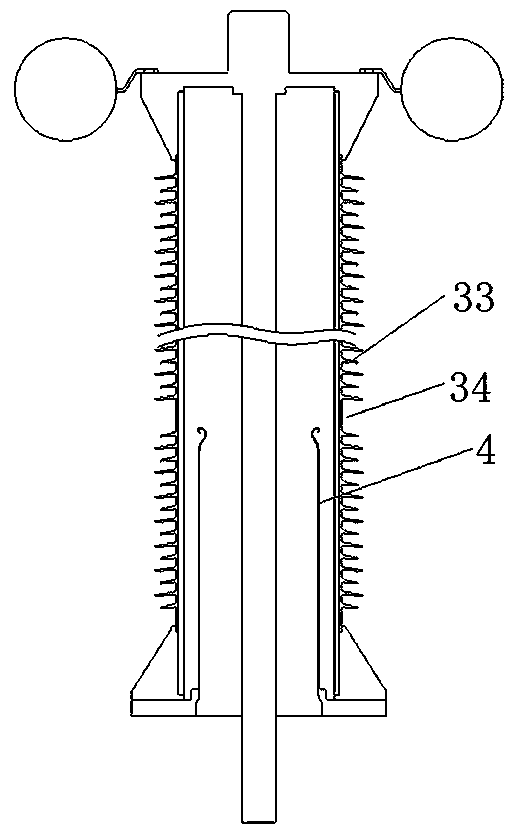

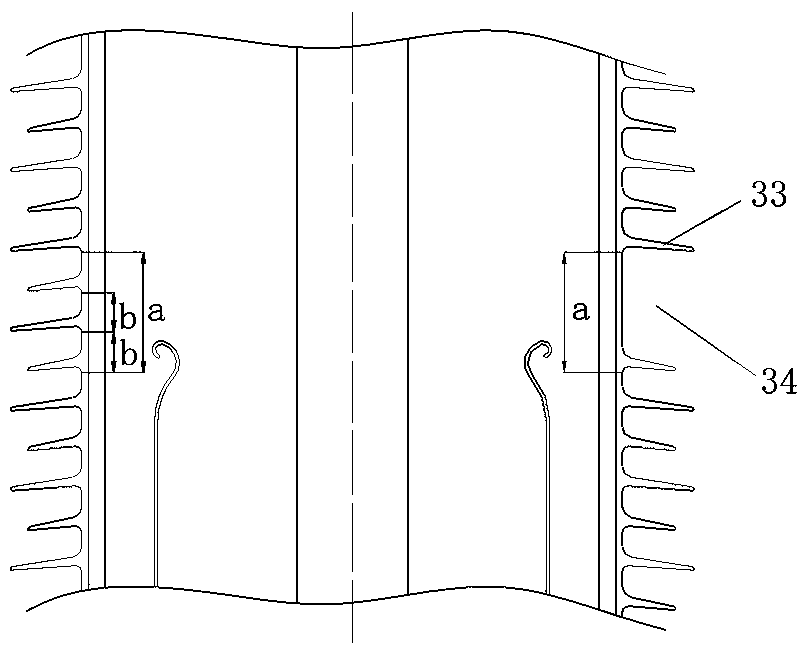

[0035] Specific embodiment 1 of the high-voltage electrical equipment of the present invention, such as Figure 2 to Figure 8 As shown, the high-voltage electrical equipment includes an equipment base on which a high-voltage bushing is installed, and the high-voltage bushing of the present invention is a 550kV high-voltage bushing. The high-voltage bushing includes a sleeve body 3 and a high-voltage conductor 2 arranged at the center of the sleeve body 3. A high-potential flange 1 is installed on one end of the sleeve body 3, and a low-potential flange 5 is installed on the other end. The high-voltage conductor 2 is installed on the high-voltage bushing. On the potential flange 1, the shielding tube 4 is worn on the high-voltage conductor 2 and the lower end is installed on the low-potential flange 5. Shielding tube 4 between body 3, shed skirt 33 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com