Solar cell module for building roof and packaging technology

A technology of solar cells and components, applied in the field of solar cells, can solve the problems of monotonous solar cell roof structure, single structure of solar cell components, loss, etc., and achieve the effects of improving wind resistance, convenient construction, and simplified wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

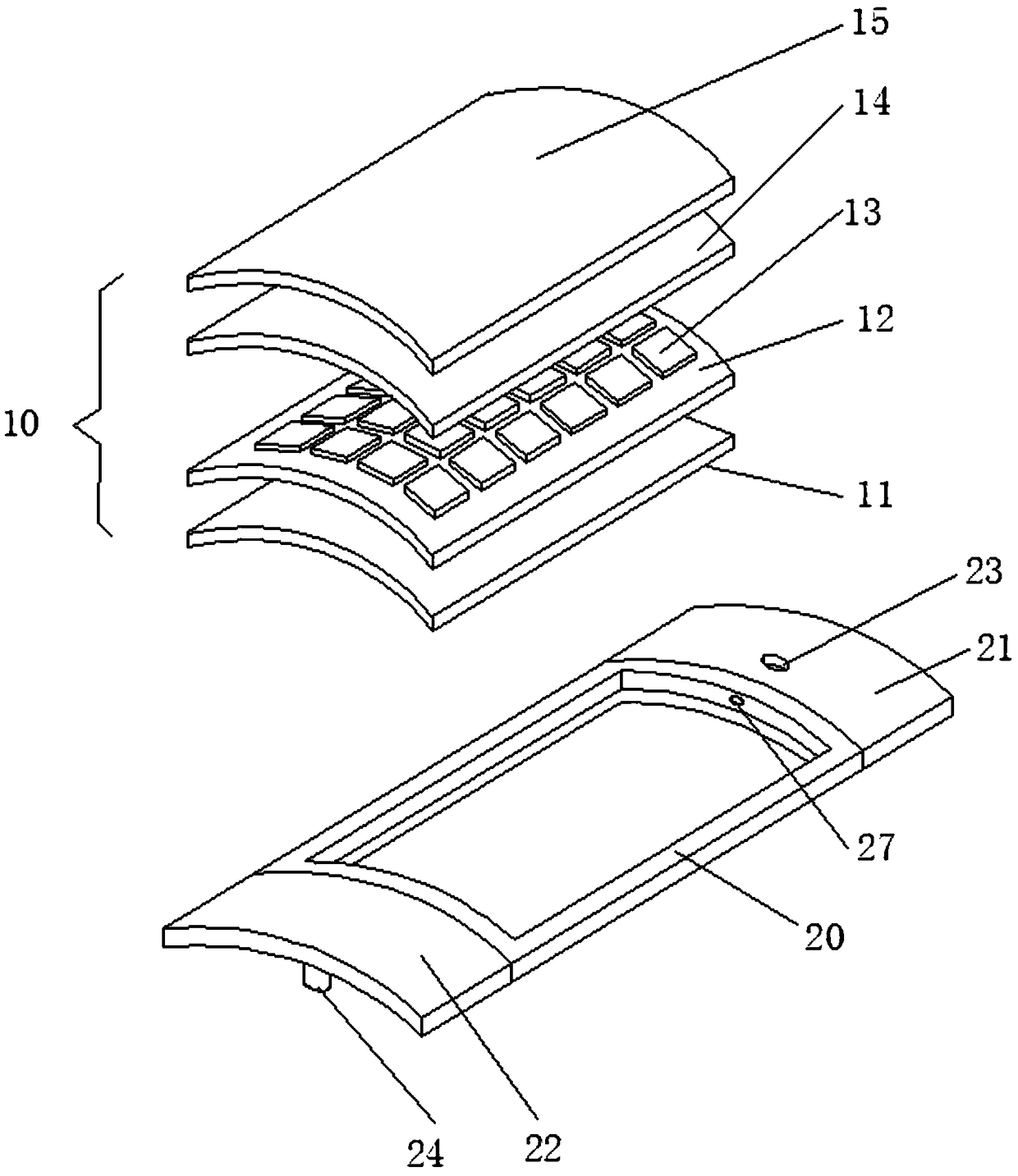

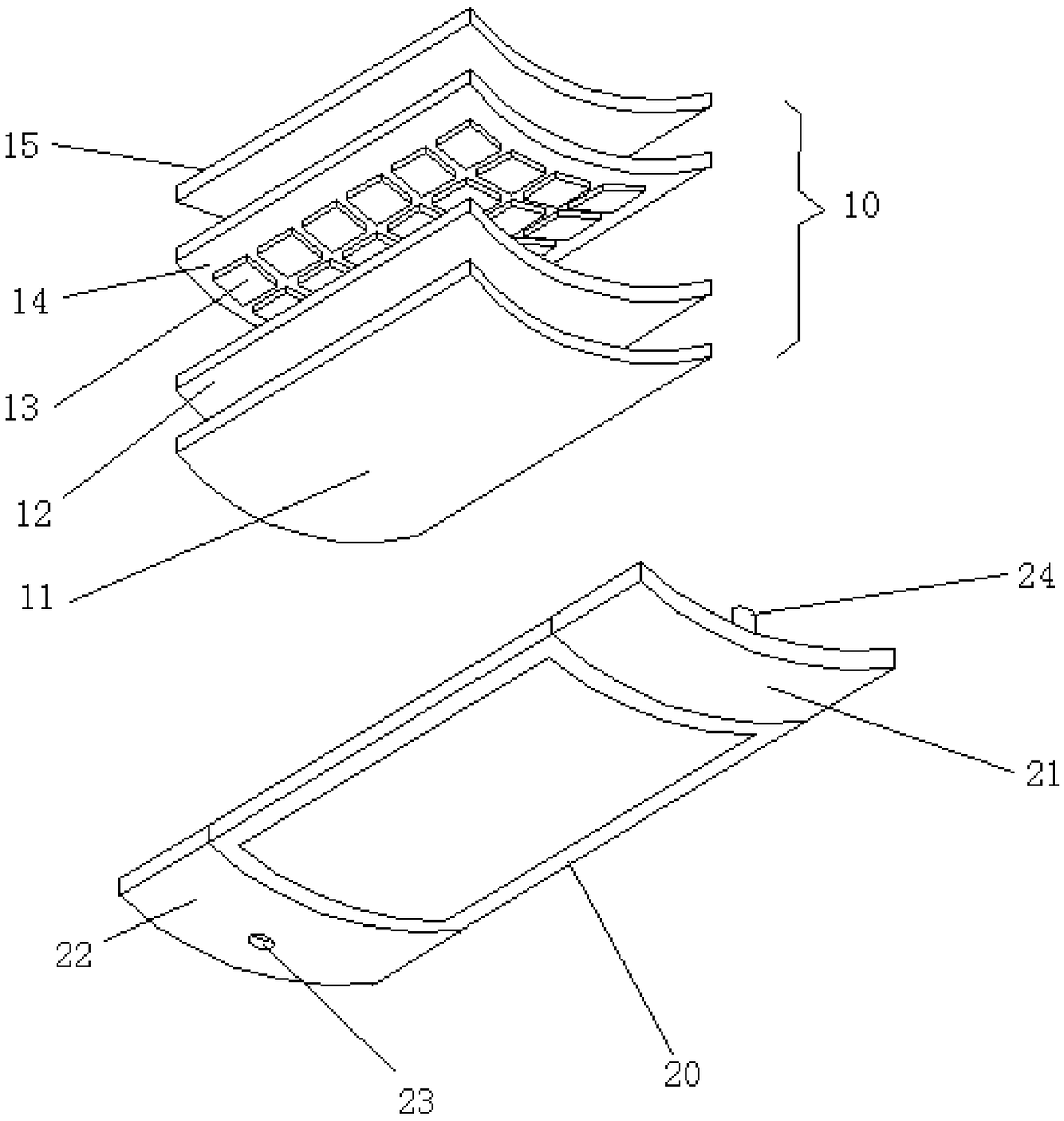

[0054] Such as figure 1 , Figure 3 to Figure 5 , Figure 7 Shown is an embodiment of a solar cell assembly for building roofs of the present invention, including a tile-shaped solar cell package body 10 with an upward arc-shaped protrusion, used for installing the solar cell package body 10 and cooperating with the solar cell package body 10 A solar cell frame 20 that is adapted to the four sides of the solar cell package 10, the solar cell package 10 is a five-layer stacked structure, and the five-layer stacked structure includes a back sheet layer 11, a first sealant layer stacked in sequence Layer 12, crystalline silicon solar cell layer 13, second sealant layer 14, glass layer 15, the back sheet layer 11, first sealant layer 12, crystalline silicon solar cell layer 13, second sealant layer 14, The glass layers 15 each have a tile-like structure that protrudes upward in an arc shape.

[0055] The solar cell package 10 in the above technical solution has an upwardly cur...

Embodiment 2

[0065] Such as Figure 2 to Figure 4 , Image 6 , Figure 7 Shown is an embodiment of a solar cell assembly used for building roofs in this embodiment, including a tile-shaped solar cell package 10 with a downward arc-shaped protrusion, used for installing the solar cell package 10 and The solar cell frame 20 adapted to the four sides of the solar cell package 10, the solar cell package 10 is a five-layer stacked structure, and the five-layer stacked structure includes a backsheet layer 11, a first layer stacked in sequence Sealant layer 12, crystalline silicon solar cell layer 13, second sealant layer 14, glass layer 15, the back sheet layer 11, first sealant layer 12, crystalline silicon solar cell layer 13, second sealant layer 14. The glass layers 15 all have a tile-like structure that protrudes downward in an arc shape.

[0066] Wherein, the front end of the solar cell frame 20 is provided with a front junction box 21, and the rear end of the solar cell frame 20 is pro...

Embodiment 3

[0070] Such as Figures 1 to 7 Shown is an embodiment of the encapsulation process of a solar cell module used for building roofs in this embodiment, including the following process steps:

[0071] Step 1, cell detection process;

[0072] Step 2, cell welding process: use tin-plated copper strips to string the cells, which includes welding the front side of the cells and welding the reverse side of the cells;

[0073] Step 3. Lamination process: lamination is carried out in the order from bottom to top, including glass layer 15, second sealant layer 14, battery sheet layer 13, first sealant layer 12, and backplane layer 11;

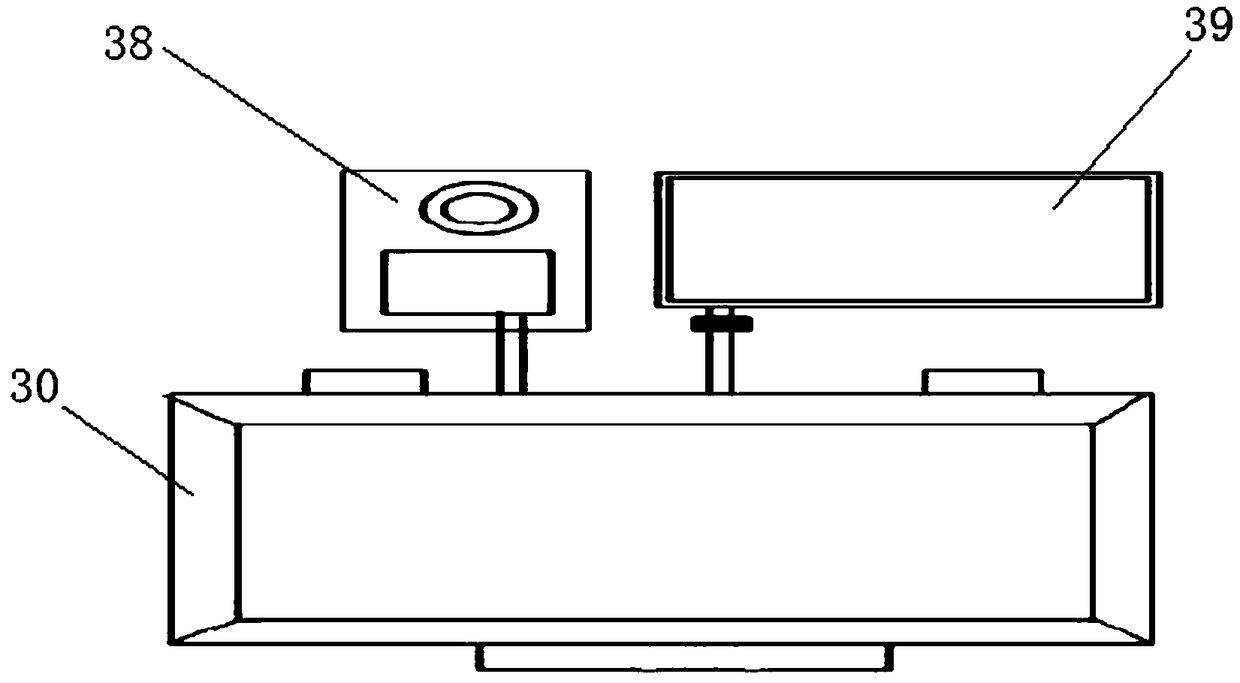

[0074] Step 4. Lamination process: Put the stacked components into the lamination machine, vacuumize, heat and laminate, and take them out after cooling; wherein, the lamination machine is used to heat the stacked components The heating plate 31 has a positioning surface adapted to the arc-shaped convex structure of the glass layer 15 in the solar cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com