Power divider

A power divider and spiral inductor technology, applied in the microwave field, can solve the problems of large volume and weight, high cost, poor stability of the power divider, etc., and achieve the effect of compact structure, high weldability and reduction of overall size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

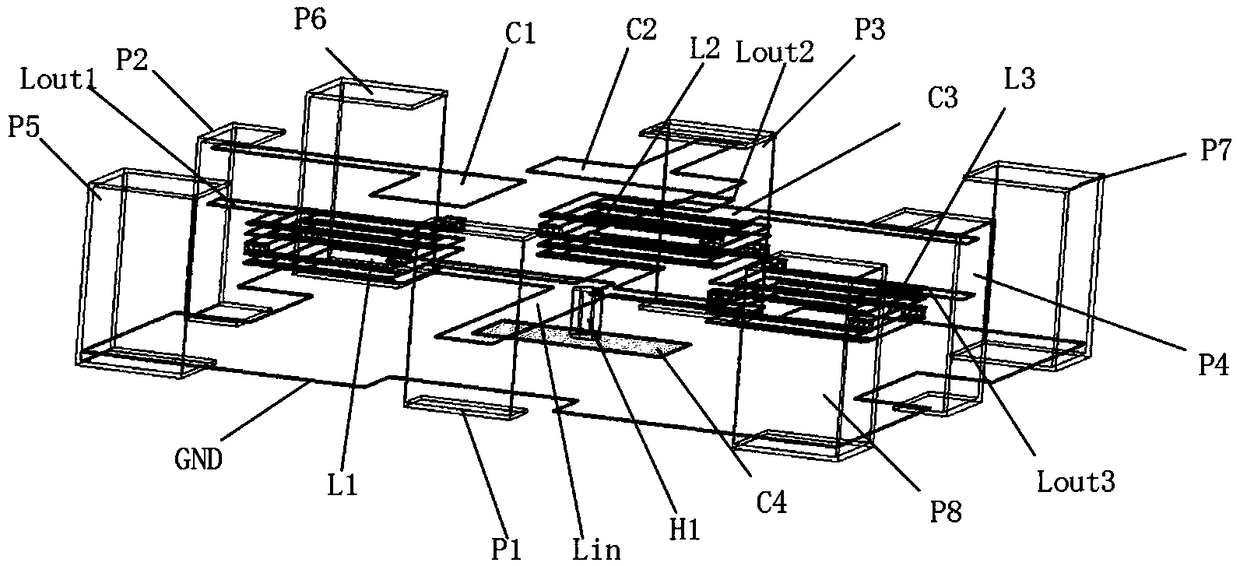

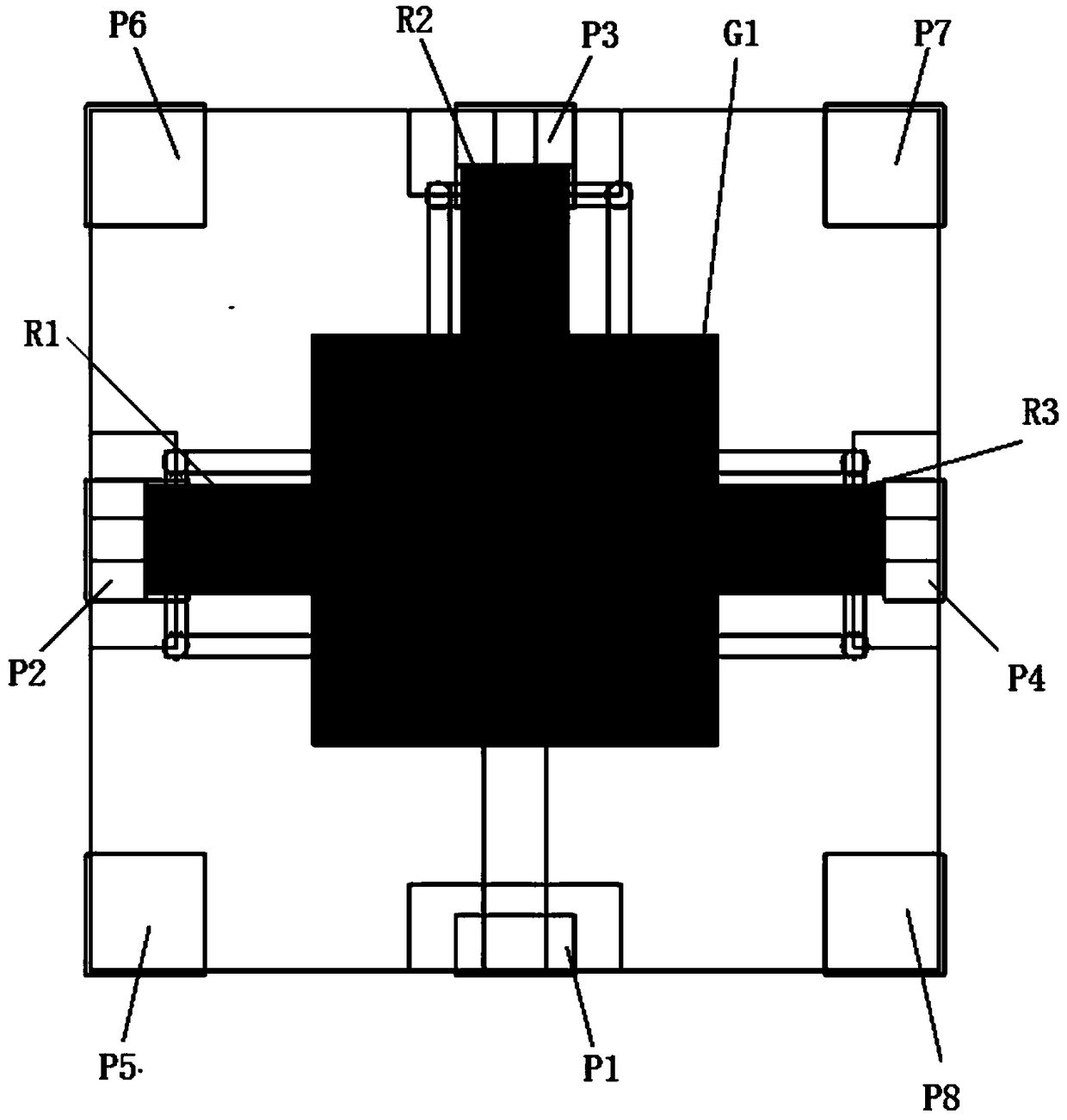

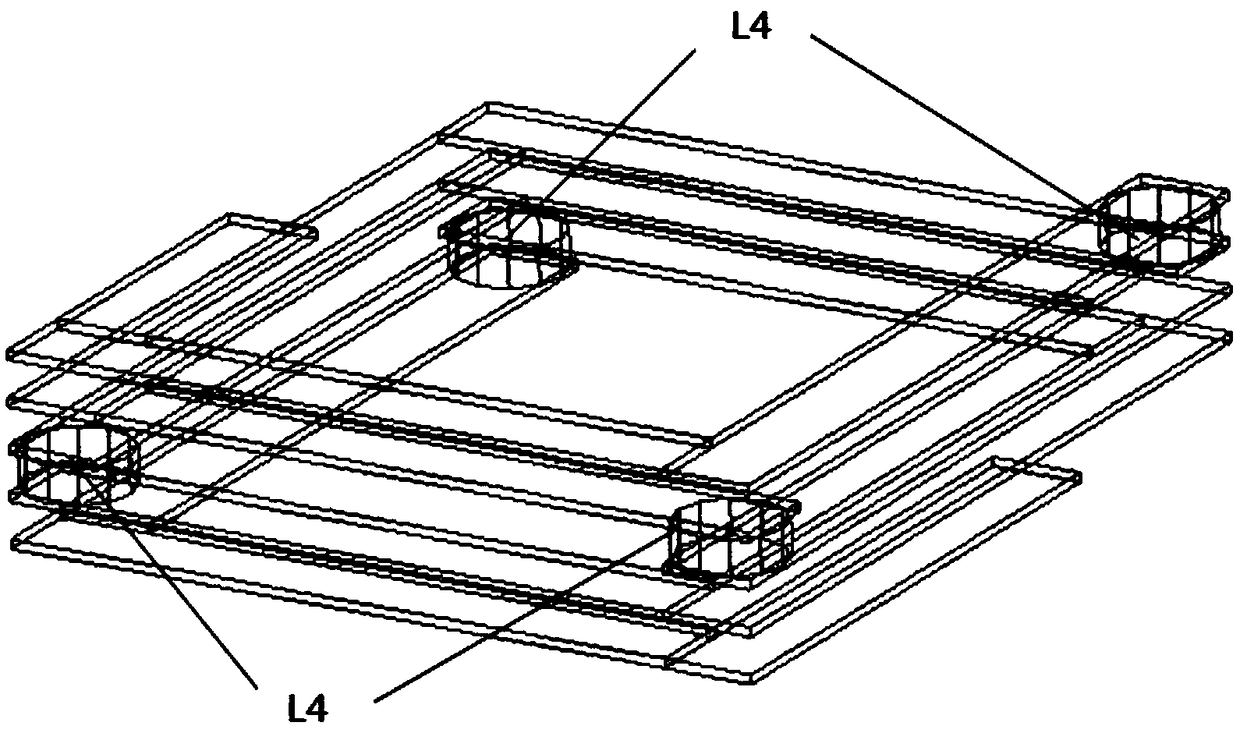

[0045] Such as figure 1 Shown is a schematic diagram of a three-dimensional structure of a power divider of the present invention, figure 2 shown as figure 1 The top view of the power divider includes a three-dimensional structure power divider core component, and the power divider core component includes a lumped capacitor with a compact structure from top to bottom, a square three-dimensional multi-layer spiral structure set The total spiral inductance and the input lead Lin are 3D packaged by LTCC technology to form a power splitter with a compact structure;

[0046]The lumped spiral inductor and the lumped capacitor directly above it constitute three sets of LC impedance matching transformation sections, which can replace the traditional quarter-wavelength transmission line, and can simultaneously achieve higher impedance values while reducing the plane size. At the same time, the matching of the output ports is improved, and the isolation between each port is increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com