Drying device of printer

A technology of drying device and printing machine, applied in printing machine, printing machine, general parts of printing machine, etc., can solve the problems of uncontrollable drying temperature and lack of cooling device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

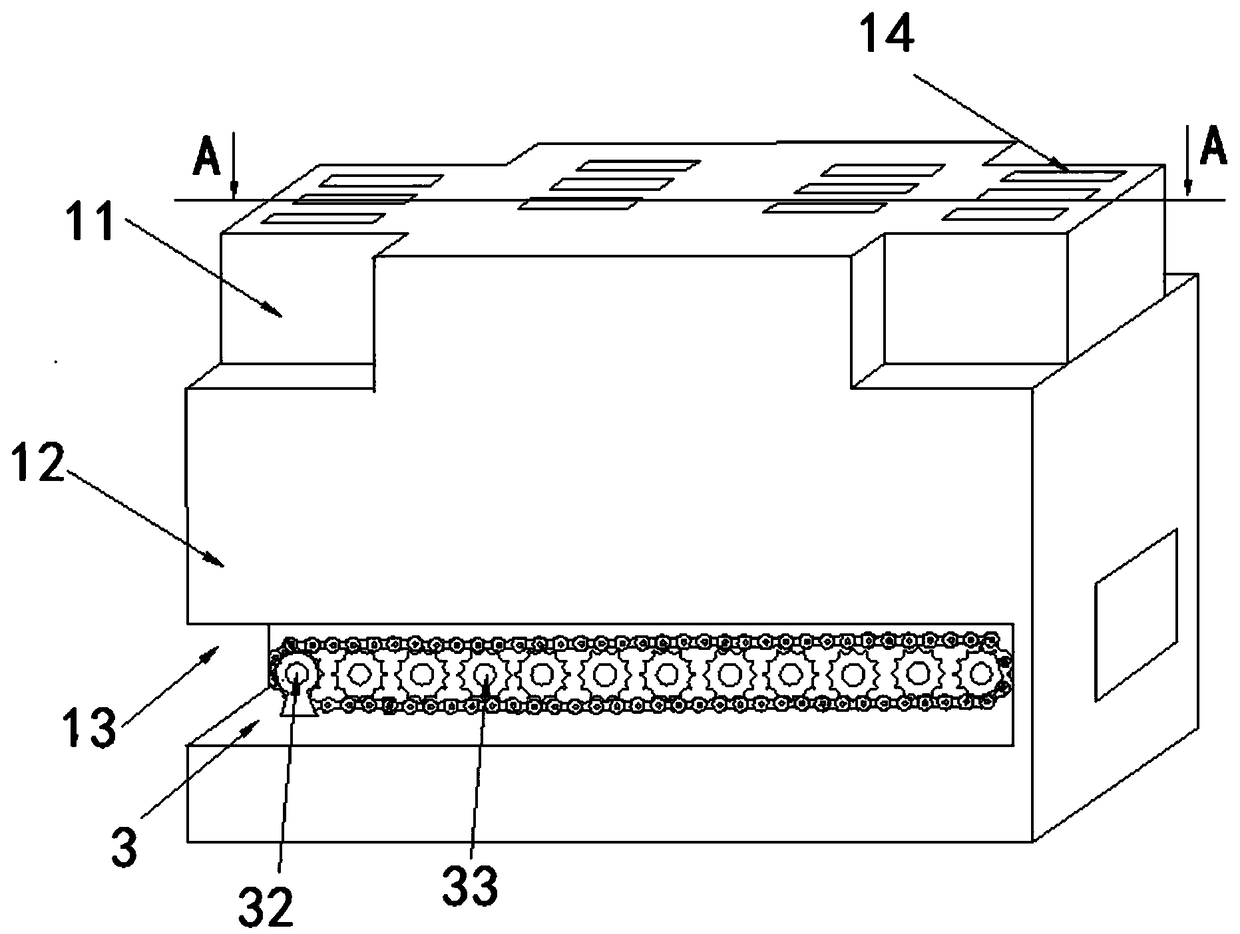

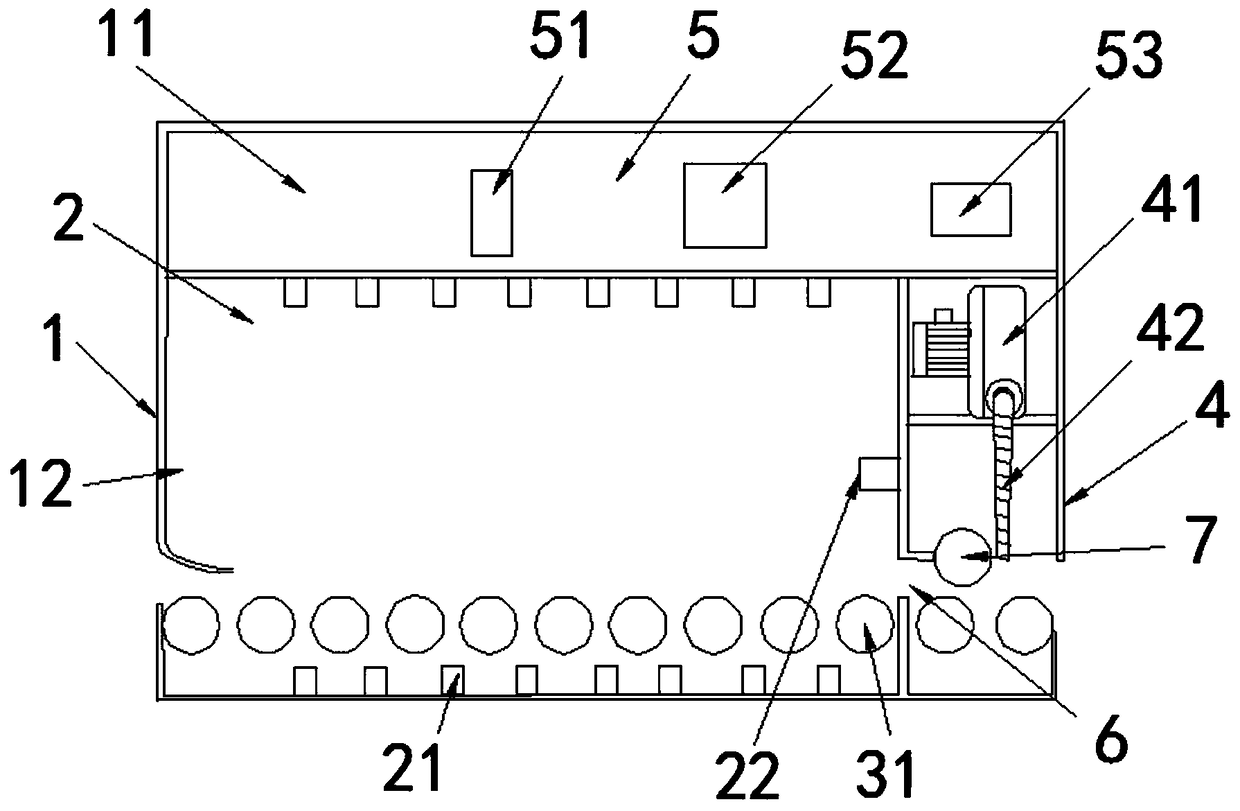

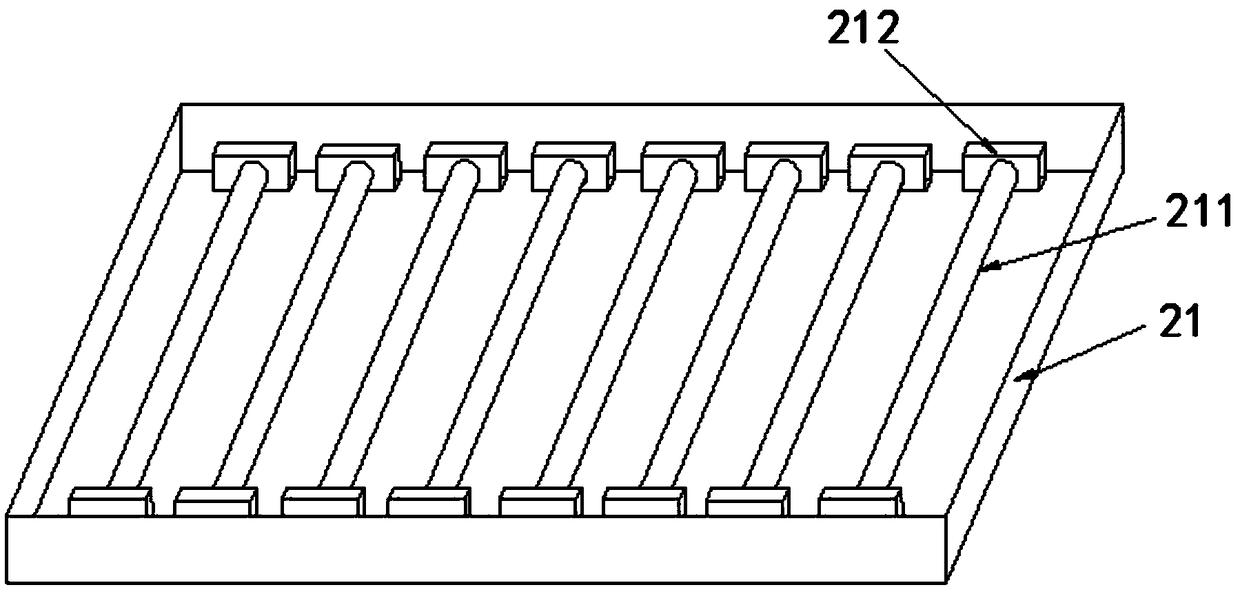

[0019] Embodiment 1 discloses a printing press drying device, such as figure 1 and figure 2 As shown, it includes a box body 1, a heating unit 2, a transmission unit 3, a cooling unit 4 and a control unit 5. Both sides of the box body 1 are respectively provided with a paper inlet and a paper outlet, as image 3 As shown, the heating unit 2 includes a heating element 21, and the heating element 21 is installed inside the box body 1. The box body 1 is divided into a box body top 11 with a "+" shape structure and a box body bottom 12 with a rectangular structure. The box body top 11 is also There are oblong cooling holes 14, and the number of oblong cooling holes 14 is 12. The heating unit 2 and the cooling unit 4 are installed side by side at the bottom of the box body 1, and the heating unit 2 and the cooling unit 4 are separated by a steel plate (not marked in the figure), and a paper transfer channel is opened on the steel plate (not marked in the figure). Hole 6, a circu...

Embodiment 2

[0023] Embodiment 2 discloses a printing machine drying device, which includes a box body 1, a heating unit 2, a transmission unit 3, a cooling unit 4 and a control unit 5. Both sides of the box body 1 are respectively provided with a paper inlet and a paper outlet. The heating unit 2 includes a heating element 21, and the heating element 21 is installed inside the box body 1. The box body 1 is divided into a box body top 11 with a "+" structure and a box body bottom 12 with a rectangular structure. The box top 11 is also provided with a long There are 12 circular cooling holes 14 and 12 oblong cooling holes 14 . The heating unit 2 and the cooling unit 4 are installed side by side at the bottom of the box body 1, and the heating unit 2 and the cooling unit 4 are separated by a steel plate, and a paper transmission hole 6 is opened on the steel plate, and the right side of the paper transmission hole 6 is also A circular pulley 7 is fixed, and the vertical distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com