Loop-free complete methanation integrated process and system

A complete methanation, integrated system technology, applied in the petroleum industry, gas fuel, fuel, etc., to achieve the effect of prolonging the service life, not easy to deposit carbon, and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

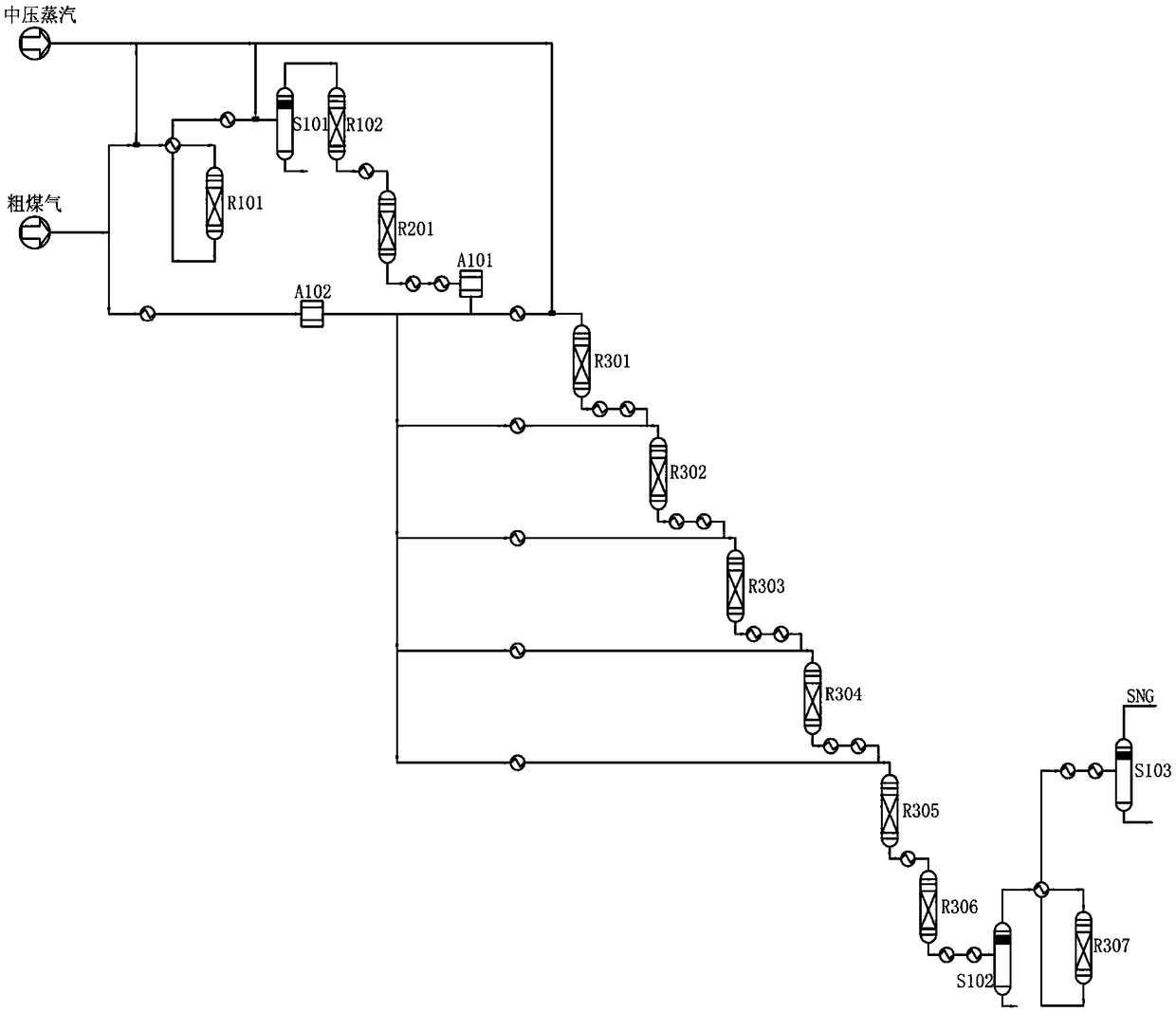

[0028] The system of the present invention will be further explained below in conjunction with the accompanying drawings:

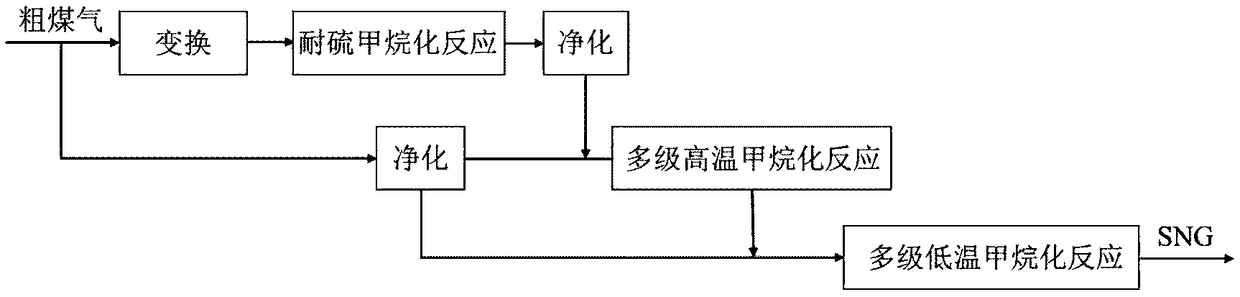

[0029]The non-circulating complete methanation integrated system of the present invention comprises a first-stage shift reaction unit R101, a shift gas-liquid separation tank S101, a second-stage shift reaction unit R102, a sulfur-resistant methanation reaction unit R301, and a first purification unit connected in sequence; A101 and Multi-stage methanation reaction unit, the multi-stage methanation reaction unit includes multi-stage high-temperature methanation reaction units R301, R302, R303, R304 connected in series and multi-stage low-temperature methanation reaction units R305, R306, R307, wherein, this implementation In the example, the methanation gas-liquid separation tank S102 and the product gas-liquid separation tank S103 are connected in series before and after the low-temperature methanation reaction unit R307 to realize gas-liquid separation; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com