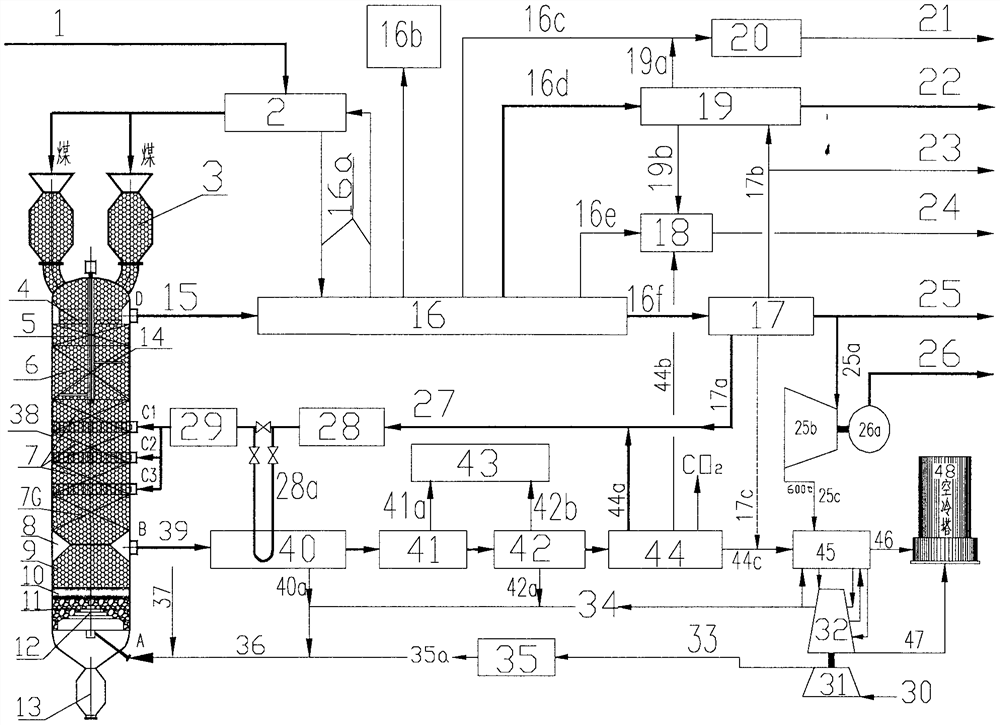

IGCC combined cycle power generation method for co-production of fuel oil and natural gas

A combined cycle power generation and natural gas technology, which is applied in the direction of combined combustion mitigation, combustible gas production, granular/powdered fuel gasification, etc., can solve problems such as single product target, underutilization of element H, and low energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0134] 1. First complete the calculation of material, heat, and power balance, and then complete the design of process, equipment, layout, and piping;

[0135] 2. Site leveling and water, electricity, gas, road and communication network construction;

[0136] 3. Equipment foundation, plant construction, equipment installation, process piping, fire protection, safety and environmental protection facilities construction;

[0137] 4. Debugging of anti-corrosion and heat preservation, electrical instrument control system, test run of water supply and circulating cooling water system, start-up and operation;

[0138] 5. Process equipment cleaning, individual test run, linkage test run; air separation, steam boiler test run, start-up, oxygen and steam output;

[0139] 6. Coal gas furnace is added to start operation, water gas is produced, and CO conversion catalyst is heated up;

[0140] 7. CO conversion, PSA desulfurization and decarbonization separation put into operation, hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com