A test system for heat storage and heating of hollow bricks

A test system, hollow brick technology, applied in regenerative heaters, gas distribution and piping systems, preheating burners, cooling water systems, measurement and control systems, and ultra-high temperature rapid valves, which can solve problems such as dust particle pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This embodiment is a ground test system for a scramjet combustion chamber.

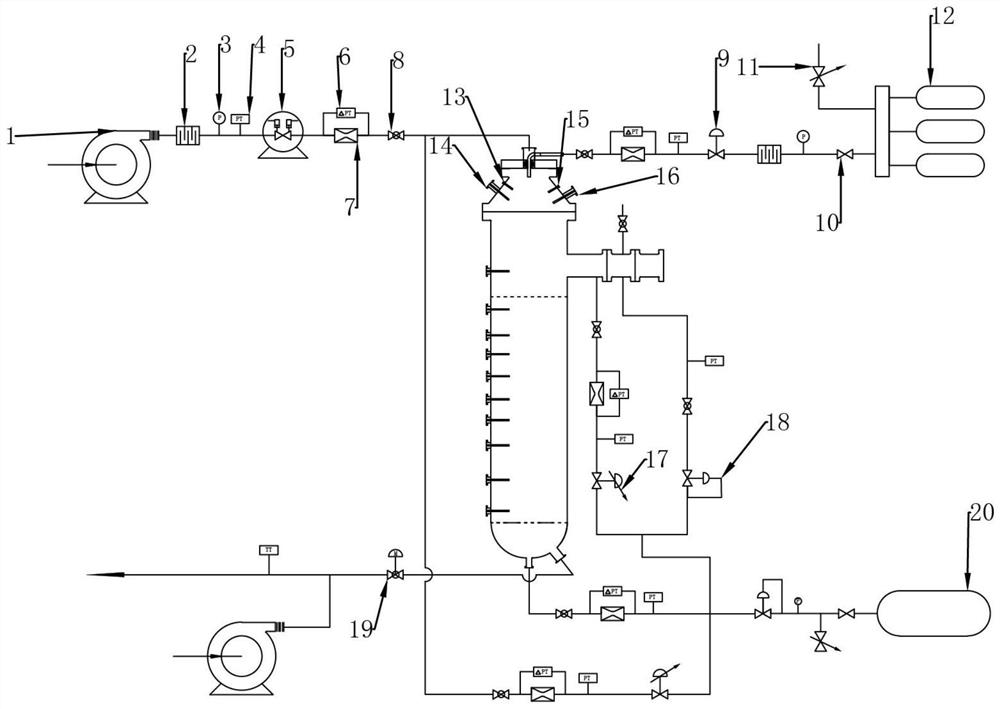

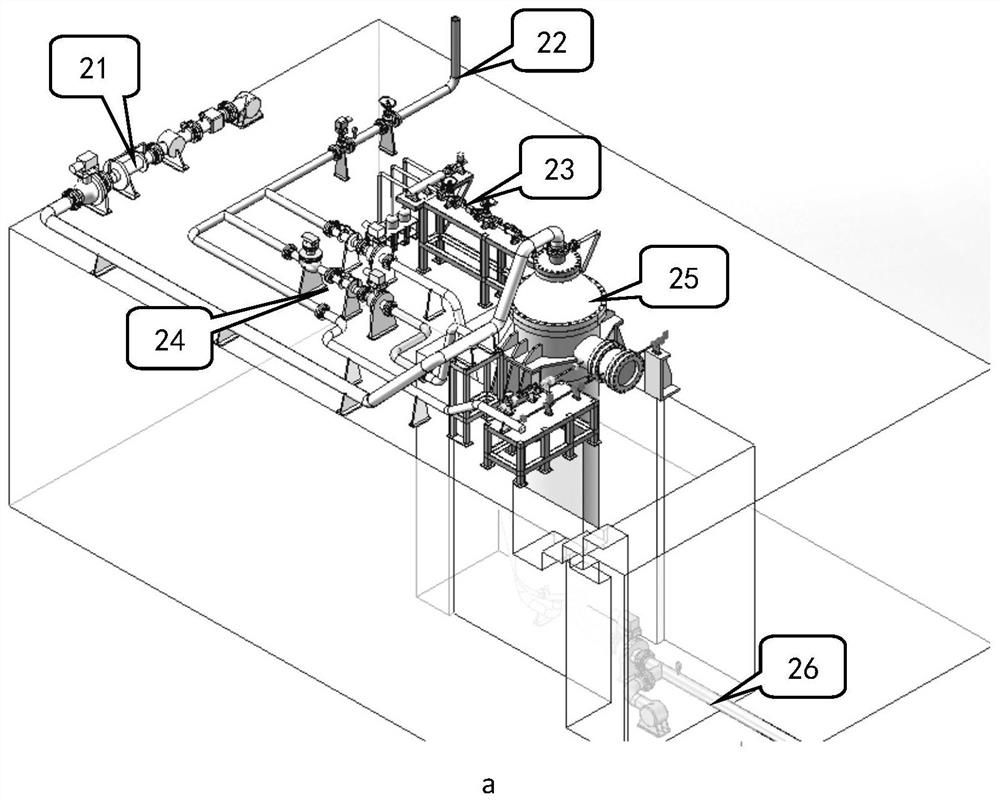

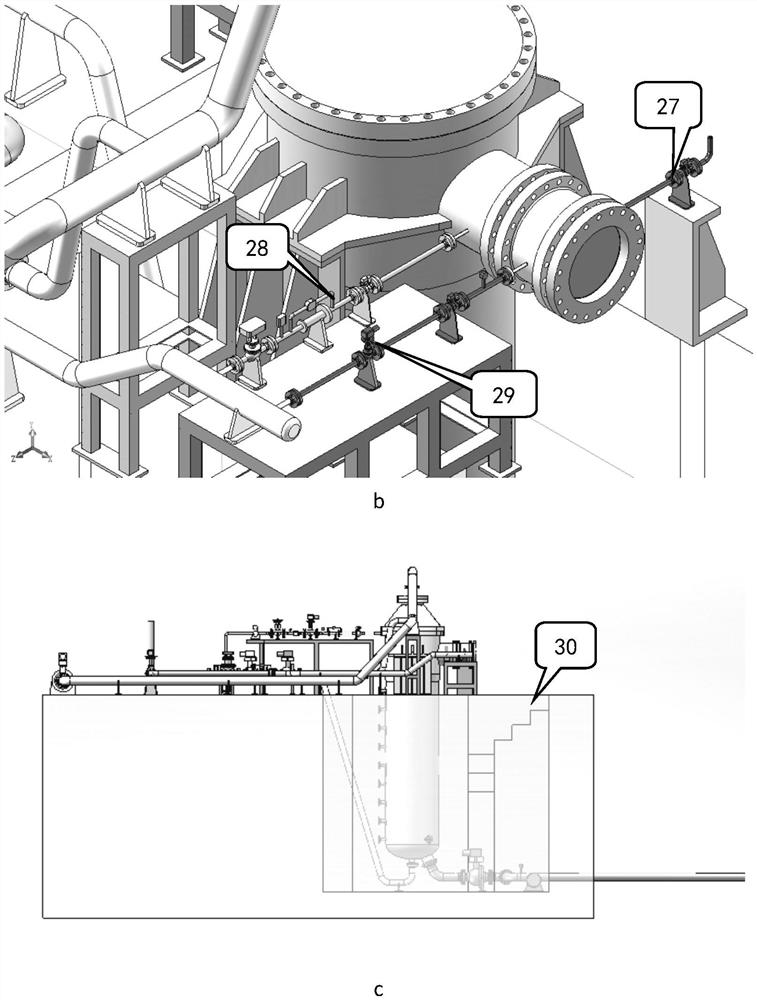

[0028] The heater structure system consists of plant foundation, equipment main body, natural gas pipes and valves, combustion air pipes and valves, high-pressure air pipes and valves, preheating burner protection pipes and valves, high-temperature pre-combustion gas discharge pipes and valves, and diaphragm protection Pipes and valves, double-chamber inflation and deflation pipes and valves, such as figure 2 (a-d) shown.

[0029] The area occupied by the foundation of the heater system plant is 15m×9m. To install the main body of the equipment, it is necessary to dig a trench about 5300mm deep. The trench is 6500mm long and 3700mm wide. In order to facilitate the operation and maintenance of high-temperature preheating gas discharge pipes and valves in the trench, multi-layer steps are built in the trench to the plant floor. After the main body of the equipment is installed, the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com