An analysis method for a Corynebacterium glutamicum metabolome

A Corynebacterium glutamicum, analysis method technology, applied in the field of bioengineering, to achieve the effect of promoting metabolism research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

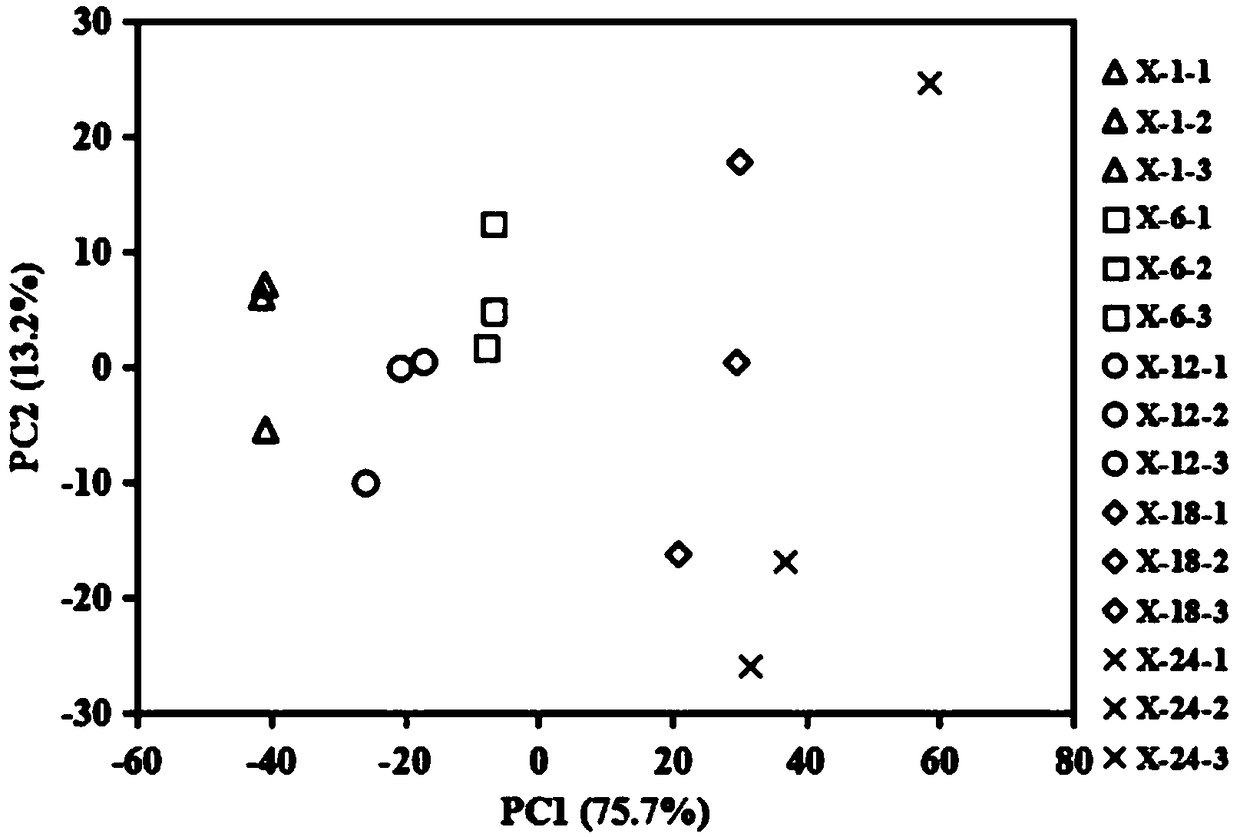

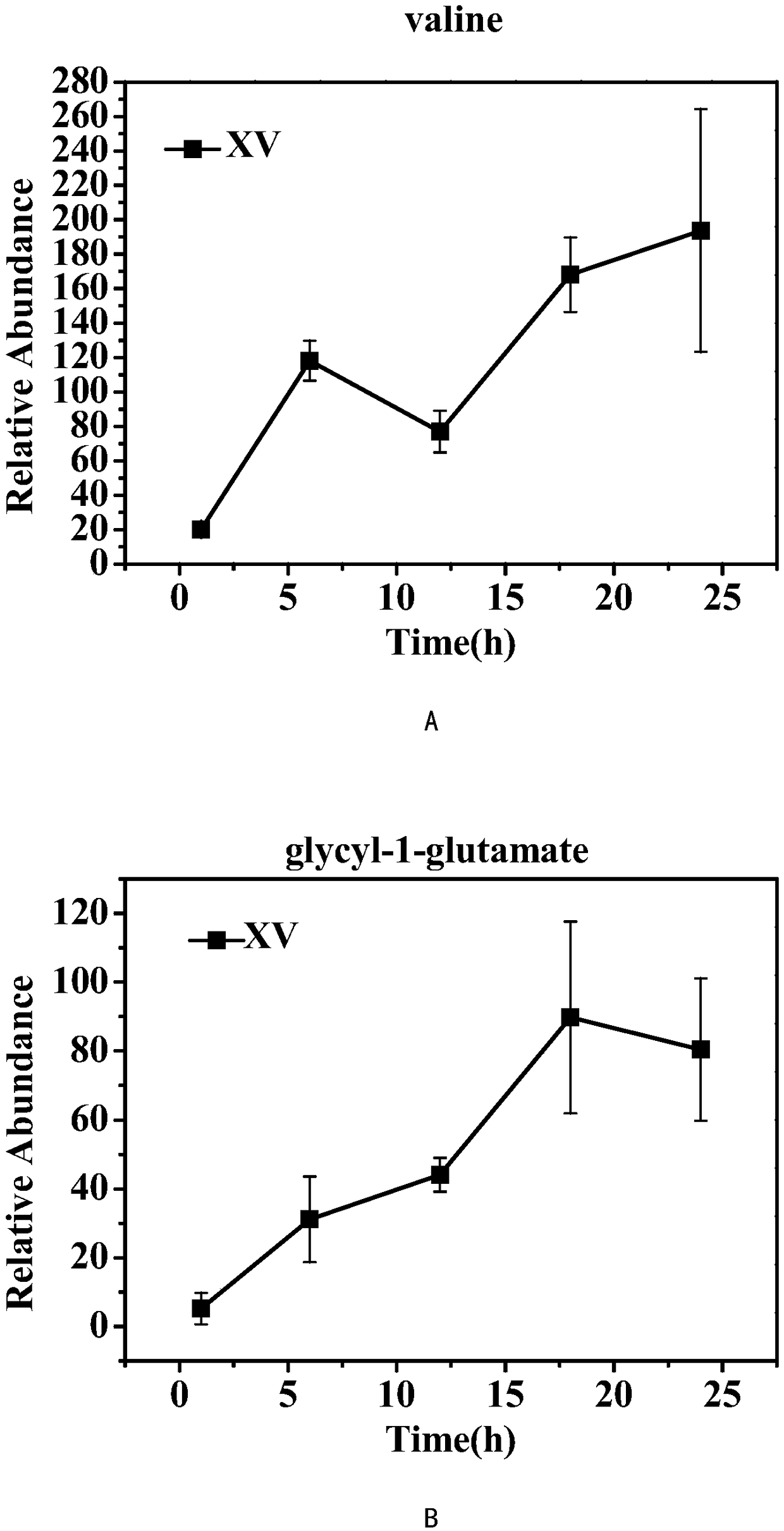

Embodiment 1

[0035] A method for analyzing the metabolome of Corynebacterium glutamicum, comprising the steps of:

[0036] (1) Corynebacterium glutamicum (Corynebacterium glutamicum) XV intracellular metabolite treatment:

[0037] ① Cell collection and quenching

[0038] A total of 5 sampling points were taken at the early stage, middle stage, and late stage of Corynebacterium glutamicum XV fermentation, and 50ml of fermentation broth was taken for each, and centrifuged at 4°C for 3min to remove most of the solid impurities in the medium. Then, centrifuge at 8000rmp, 4°C for 10min. The supernatant was discarded, and the cell pellet was washed twice with PBS buffer, and then once with deionized ultrapure water. After centrifugation, the cell pellet was placed in liquid nitrogen to quench the reaction, and stored in liquid nitrogen for later use.

[0039] Described PBS damping fluid (1mol / L) contains NaCl 8g, KCl 0.2g, NaCl 2 HPO 4 1.42g, KH 2 PO 4 0.27g

[0040] ②Metabolite extract...

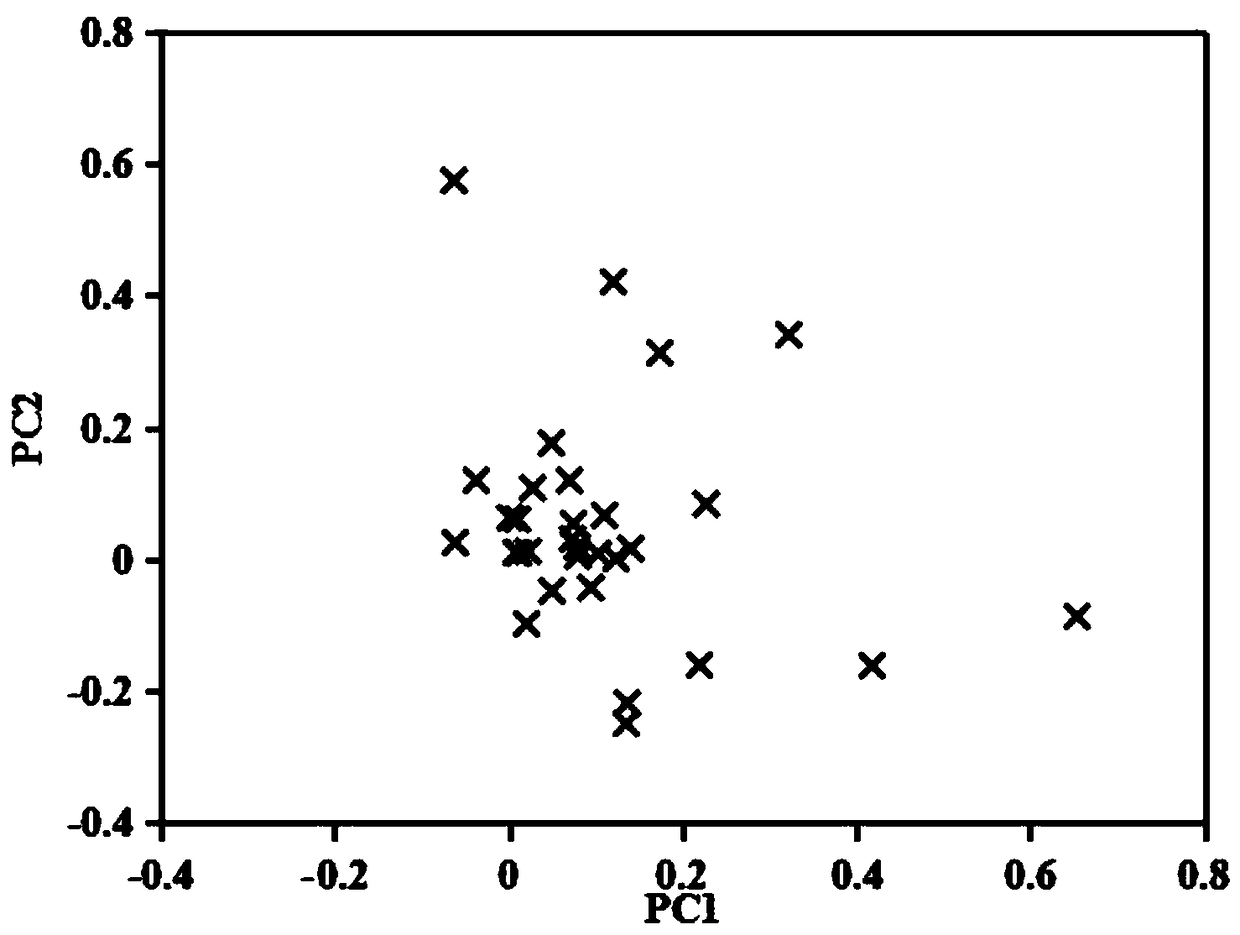

Embodiment 2

[0063] A method for analyzing the metabolome of Corynebacterium glutamicum, comprising the steps of:

[0064] (1) Corynebacterium glutamicum (Corynebacterium glutamicum) ATCC 13032 intracellular metabolite treatment:

[0065] ① Cell collection and quenching

[0066] A total of 5 sampling points were taken at the early stage, middle stage and late stage of the fermentation of Corynebacterium glutamicum (Corynebacterium glutamicum) ATCC 13032, and 60ml of fermentation broth was taken for each, and centrifuged at 4°C for 3min to remove most of the solid impurities in the medium. Then, centrifuge at 7000rmp and 4°C for 10min. The supernatant was discarded, and the cell pellet was washed twice with PBS buffer, and then once with deionized ultrapure water. After centrifugation, the cell pellet was placed in liquid nitrogen to quench the reaction, and stored in liquid nitrogen for later use.

[0067] Described PBS damping fluid (1mol / L) contains NaCl 8g, KCl 0.2g, NaCl 2 HPO 4 1...

Embodiment 3

[0077] A method for analyzing the metabolome of Corynebacterium glutamicum, comprising the steps of:

[0078] (1) Corynebacterium glutamicum (Corynebacterium glutamicum) CP intracellular metabolite treatment:

[0079] ① Cell collection and quenching

[0080] A total of 5 sampling points were taken at the early stage, middle stage, and late stage of CP fermentation of Corynebacterium glutamicum (Corynebacterium glutamicum), and 50ml of fermentation broth was taken for each, and centrifuged at 4°C for 3min to remove most of the solid impurities in the medium. Then, centrifuge at 8000rmp, 4°C for 10min. The supernatant was discarded, and the cell pellet was washed twice with PBS buffer, and then once with deionized ultrapure water. After centrifugation, the cell pellet was placed in liquid nitrogen to quench the reaction, and stored in liquid nitrogen for later use.

[0081] Described PBS damping fluid (1mol / L) contains NaCl 8g, KCl 0.2g, NaCl 2 HPO 4 1.42g, KH 2 PO 4 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com