Electro-hydraulic joint load sensitive adaptive fuzzy sliding mode control method

A load-sensitive control, adaptive fuzzy technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of reducing system robustness, weakening chattering, difficult preparation, etc. Good performance, suppressing high-frequency chattering, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

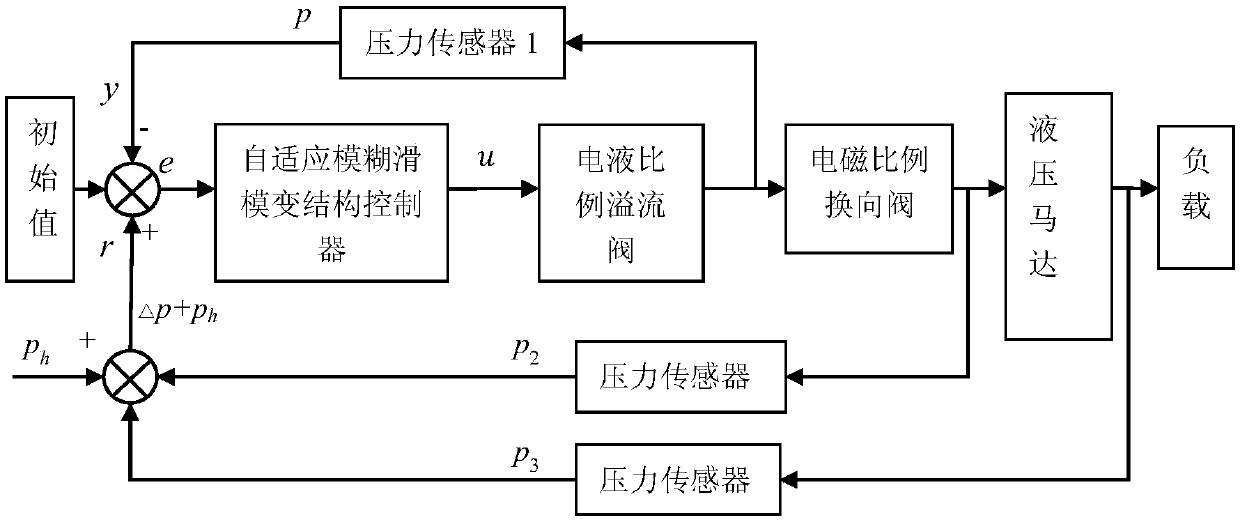

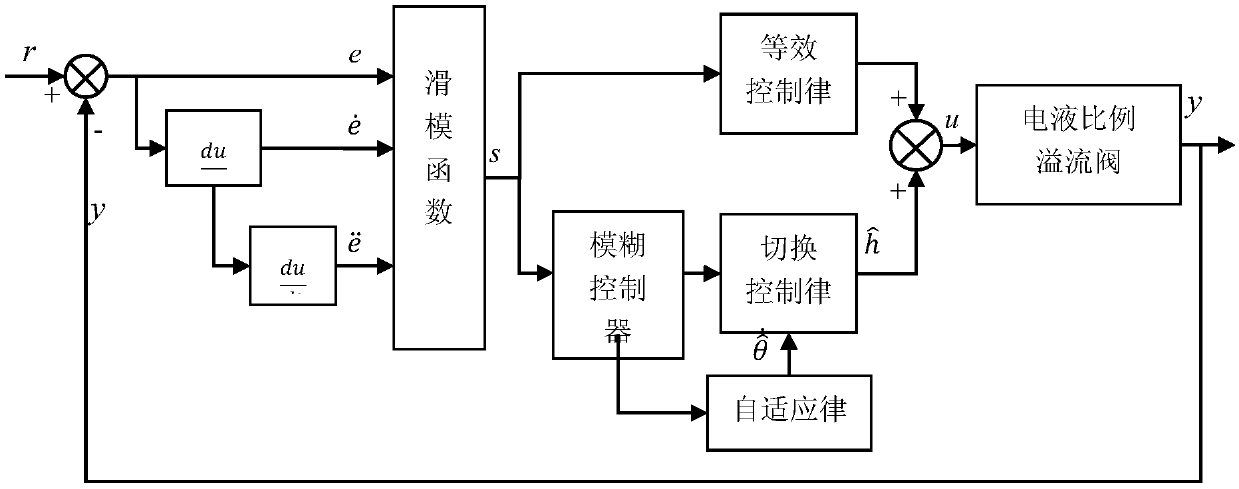

[0023] Attached below figure 1 to attach figure 2 , the present invention will be described in further detail.

[0024] Reference attached figure 1 In the early stage of operation of the electro-hydraulic joint control system mentioned in the present invention, the initial value of the pressure regulation system is given to make it operate, the proportional amplifier amplifies the given initial value, and the electro-hydraulic proportional overflow valve receives the voltage signal and performs electromagnetic conversion to drive The spool moves, and the hydraulic actuator converts the flow rate into a hydraulic oil pressure signal, and the supply and demand are sent to the actuator, that is, the hydraulic motor, so that its operation drives the load to complete the drive demand. After that, there is no need to give any driving signal from the outside, and the control system will automatically compensate the pressure according to the load condition. According to the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com