Mine use rail type routing inspection robot and positioning method thereof

A technology of inspection robot and positioning method, applied in attitude control, navigation through speed/acceleration measurement, etc., can solve the problems of difficult and unfavorable positioning site relative and absolute position information, heavy surveying and mapping workload, etc., to reduce workload and cost, easy installation and deployment, and the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

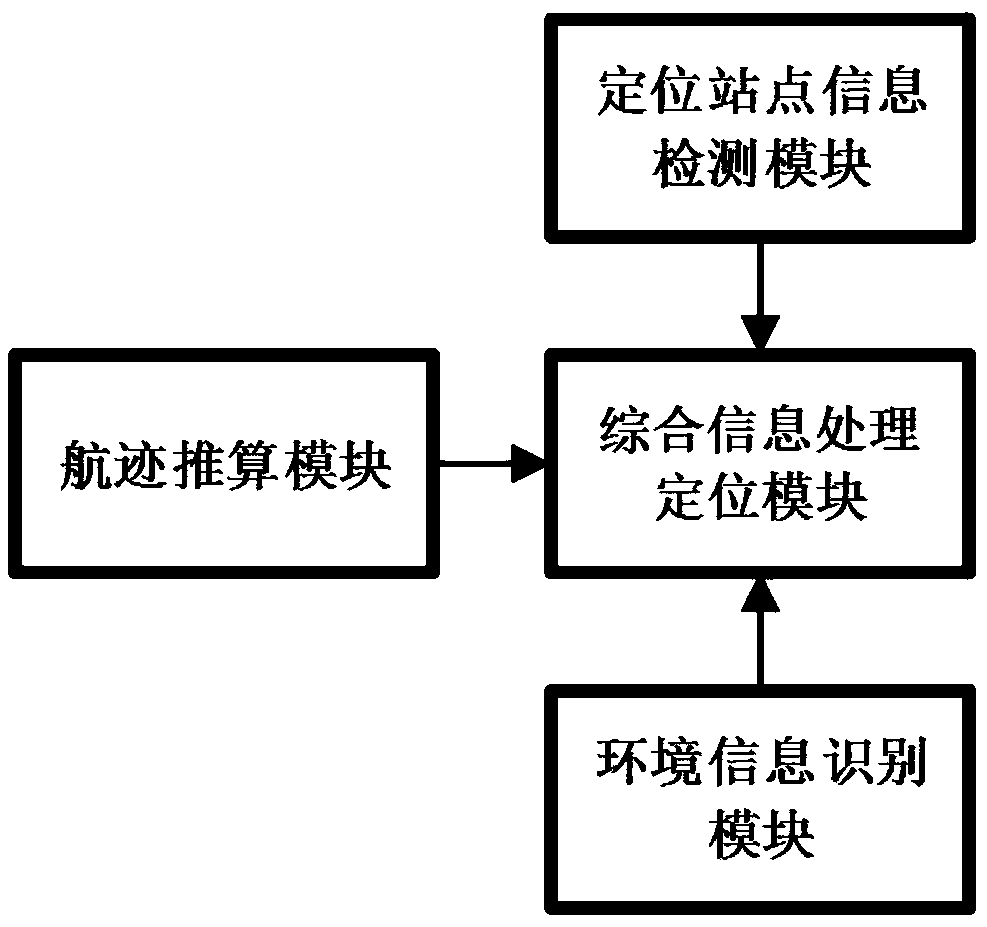

[0039] The present invention has designed a kind of track-type inspection robot for mining, in specific practical application, such as figure 1 As shown, the orbital inspection robot has a built-in dead reckoning module, a positioning station information detection module, an environmental information identification module and a comprehensive information processing and positioning module.

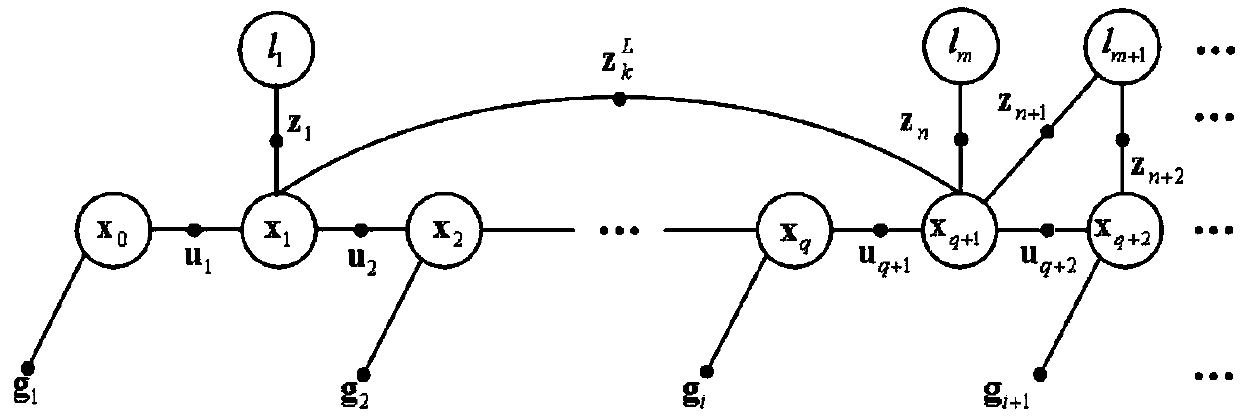

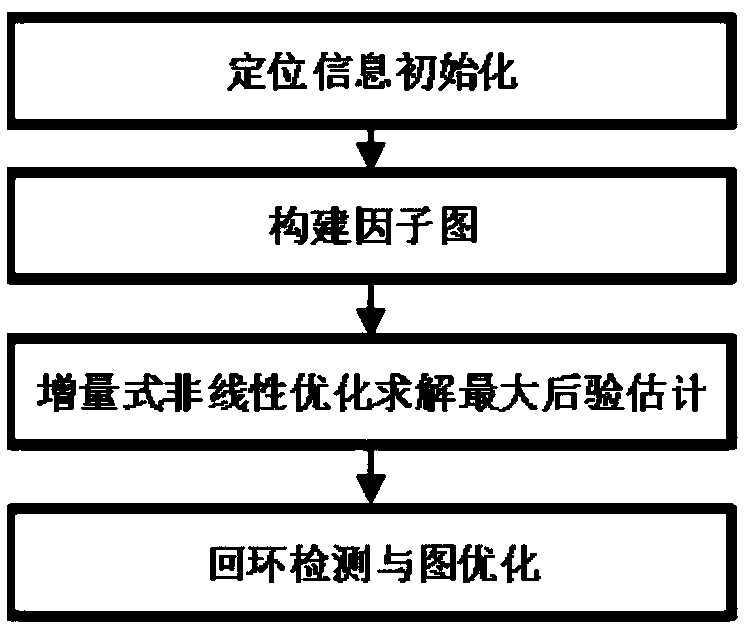

[0040] In the positioning method, as the orbital inspection robot moves in the mine, the dead reckoning module is used to apply the dead reckoning principle to realize active positioning for the orbital inspection robot, and obtain the relative position relationship of the orbital inspection robot in real time. As a real-time relative pose transformation constraint model of an orbital inspection robot, it is added to the factor graph m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com