Accelerator

A kind of accelerator, the technology of curing accelerator, applied in the purpose of function, prepares the composition that comprises at least one kind of mineral binder, molded body, promotes the field of curing of mineral binder, can solve limited application field, expensive , Mortar and concrete processing time and final strength unfavorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] 1. Materials and methods

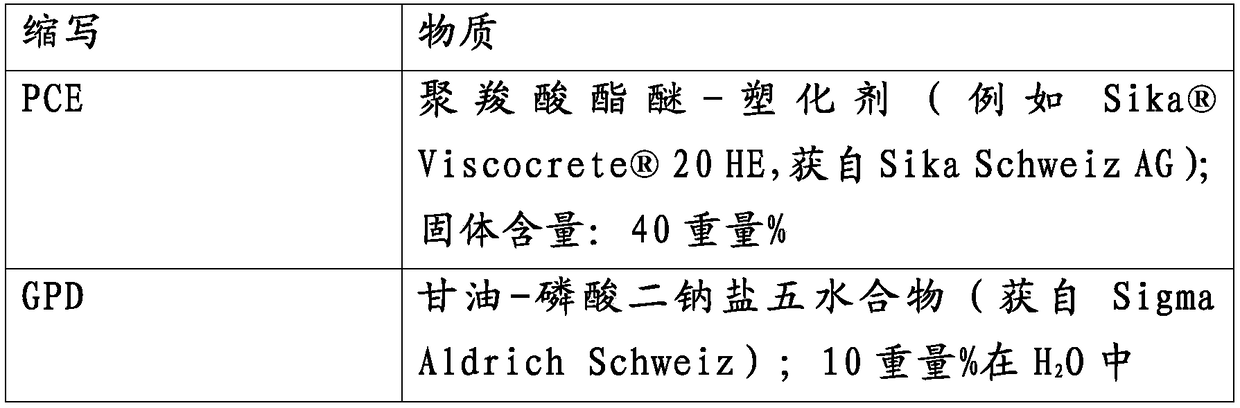

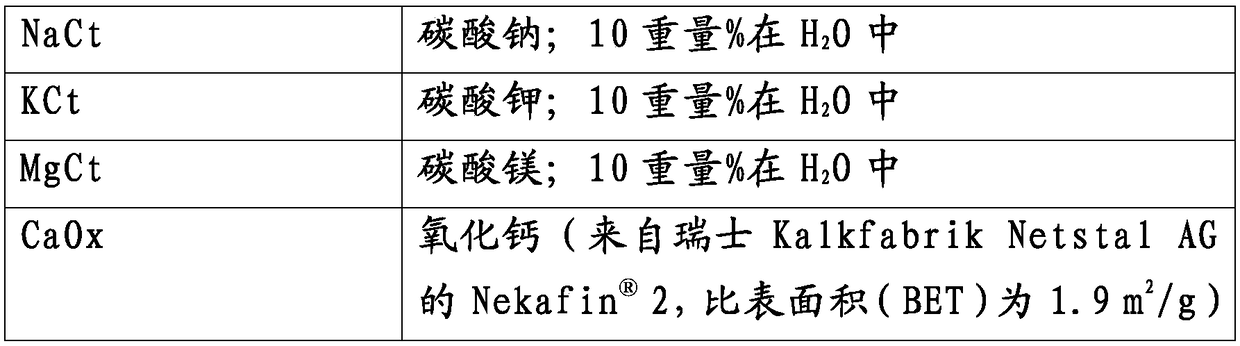

[0097] 1.1. Substance

[0098] Examples The following materials were used:

[0099] Table 1: Substances used

[0100]

[0101]

[0102] Sodium, potassium and magnesium carbonates were obtained commercially in pure form (>97% purity) from various suppliers. These were each dissolved in water in the amounts given in Table 1 and used in the form of aqueous solutions.

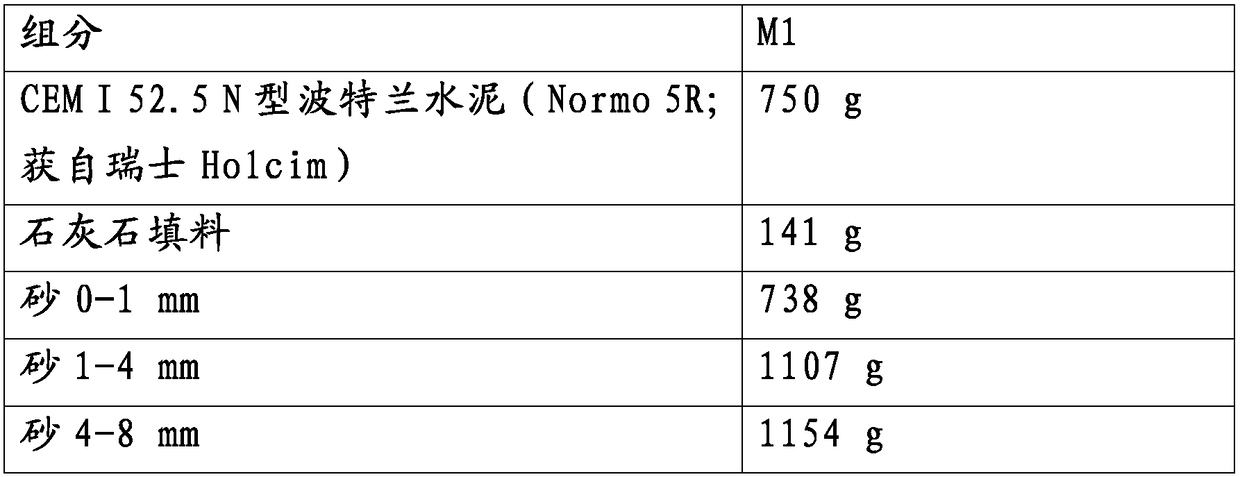

[0103] 1.2 Mortar mixture

[0104] The mortar mixture M1 used had the dry composition described in Table 2.

[0105] Table 2: Dry Composition of Mortar Mixtures

[0106]

[0107] For mixing the mortar mixture, sand, limestone filler, cement and optionally calcium oxide (CaOx) were dry mixed in a Hobart-mixer at a temperature of 20° C. for 1 minute. Within 30 seconds, add mixing water (water / cement-value or w / z=0.4) in which polycarboxylate ether-plasticizer (PCE; 1% by weight based on cement) and optionally other substances (GPD, NaCt, KCt, MgCt), and then stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com