Pressing-type feeding machine convenient for air suction and dust removal

A feeder and press-fit technology, which is applied in the field of animal husbandry feeders, can solve the problems of affecting the efficiency of batch material distribution, affecting the working environment, and dust emission, etc., achieving low manufacturing costs, simple device structure, and convenience. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

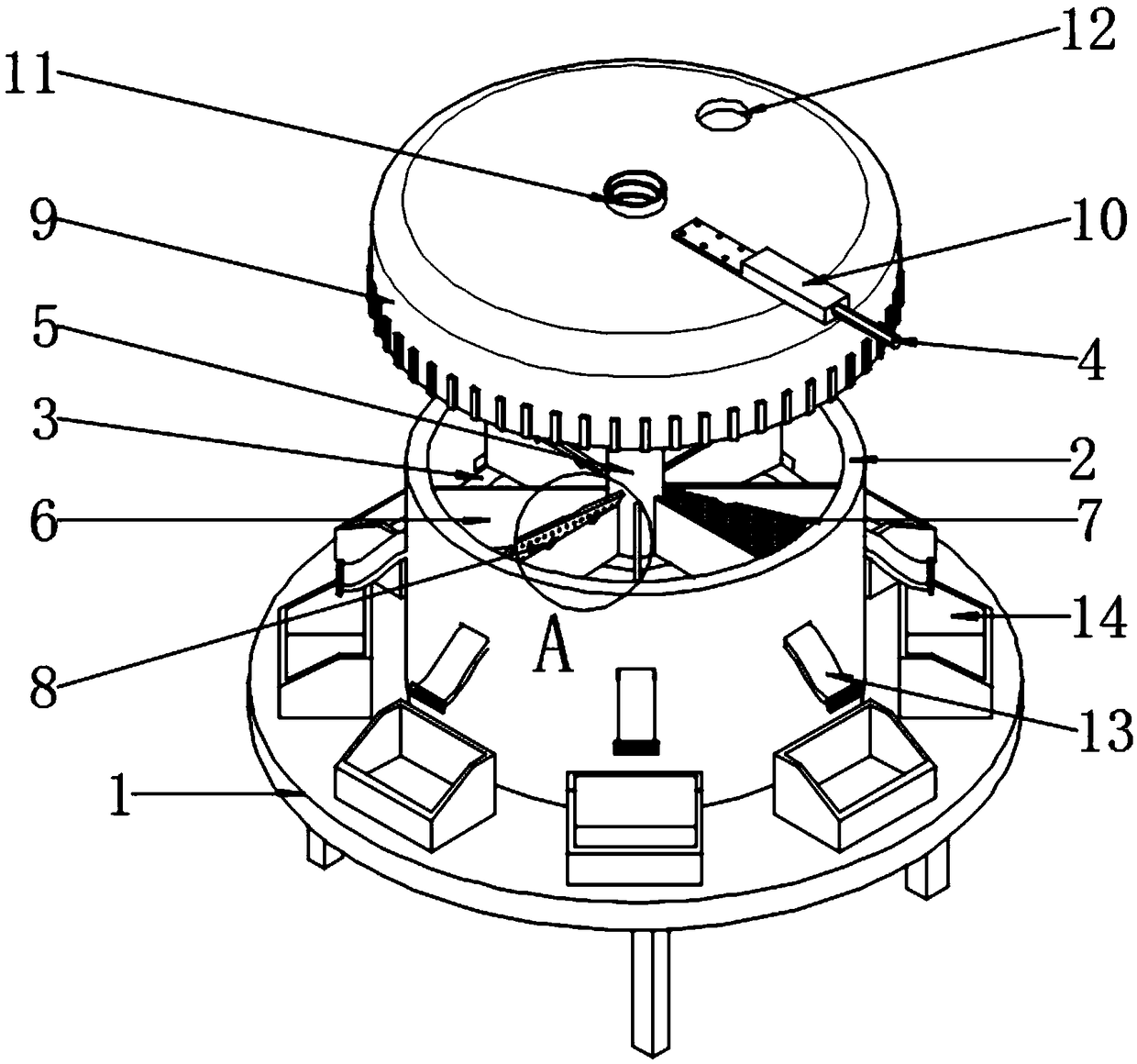

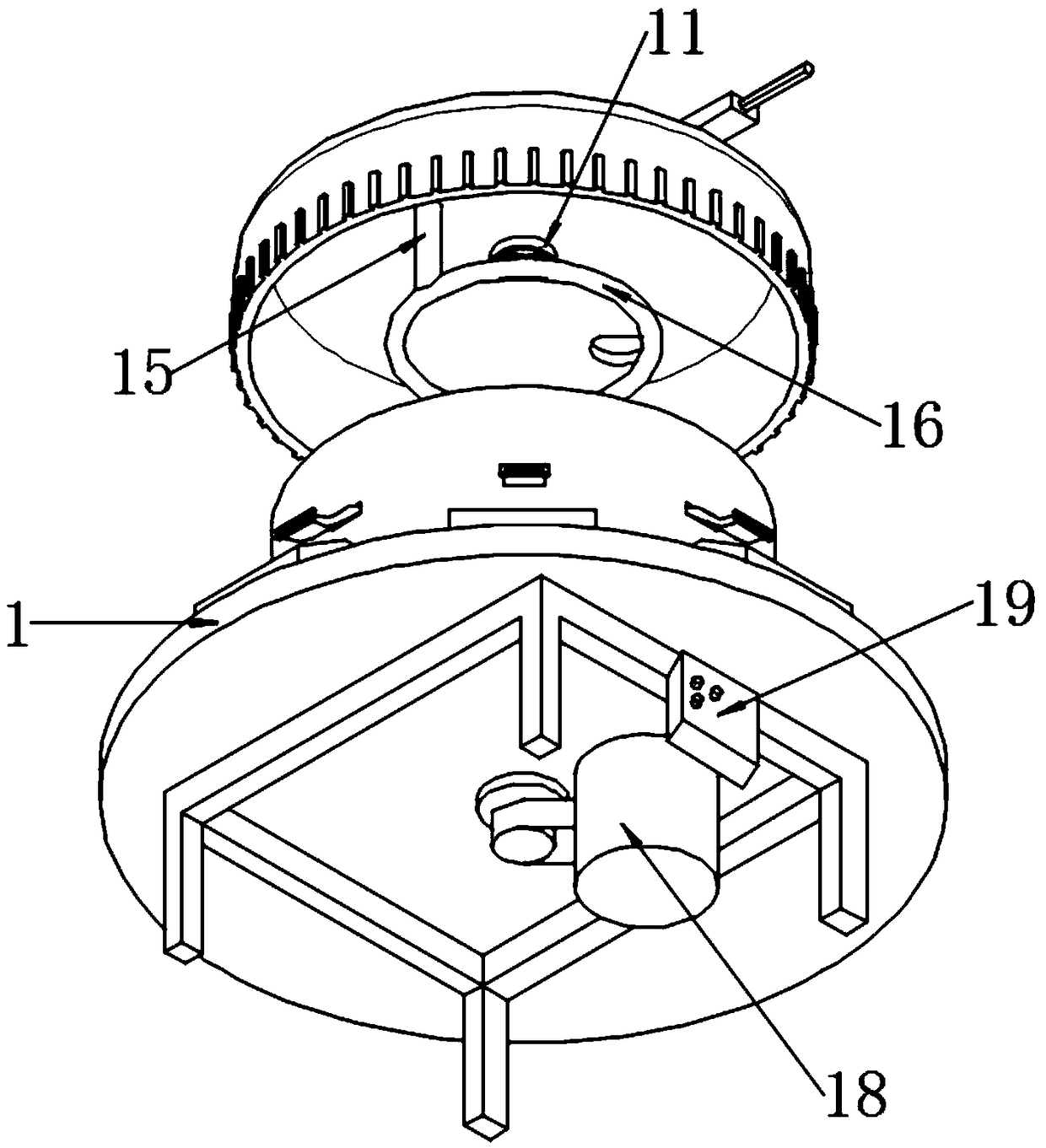

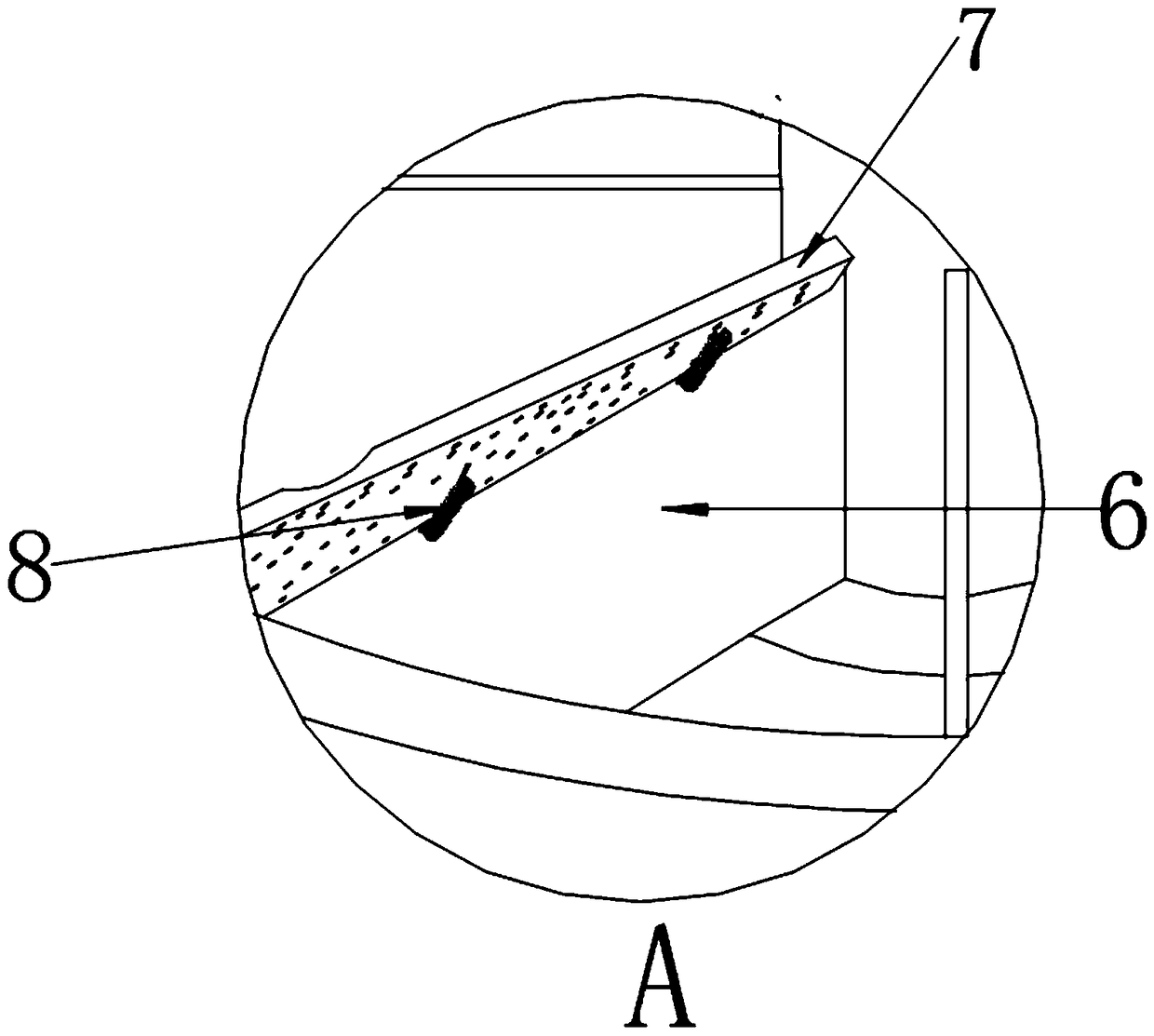

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The present invention provides a press-fit feeder that is convenient for suction and dust removal, including a base 1, a cylinder body 2, a discharge hole 201, a support plate 3, a handle 4, a rotating shaft 5, a material distribution plate 6, a connecting plate 7, Dust outlet 701, return spring 8, screw cap 9, lever 10, rotating tube 11, vacuum cleaner interface 12, sliding material tube 13, receiving seat 14, support rod 15, pressure tube 16, sliding material plate 17, motor 18 and an electrical box 19; the base 1 is a circular platform structure, and a cylinder body 2 of an integral structure is provided on its top surface, and a circle of receiving seats 14 is evenly distributed on the periphery of the cylinder body 2; the base 1 The bottom surface of the frame is a frame weldment structure, and a motor 18 and an electrical box 19 that are electrically connected to each other are installed on the bottom frame...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap