Delivery vehicle complete vehicle structure of full-integrated, modularized and total light-weighted structure and vehicle

A modular, full-loading technology, applied in the direction of load-bearing body structure, superstructure, goods transport vehicle, etc., can solve the problem of low degree of light weight, and achieve the effect of good mechanical performance, convenient manufacturing and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] This embodiment provides a fully load-bearing, modularized, and fully lightweight logistics vehicle structure, and its specific structure is described below.

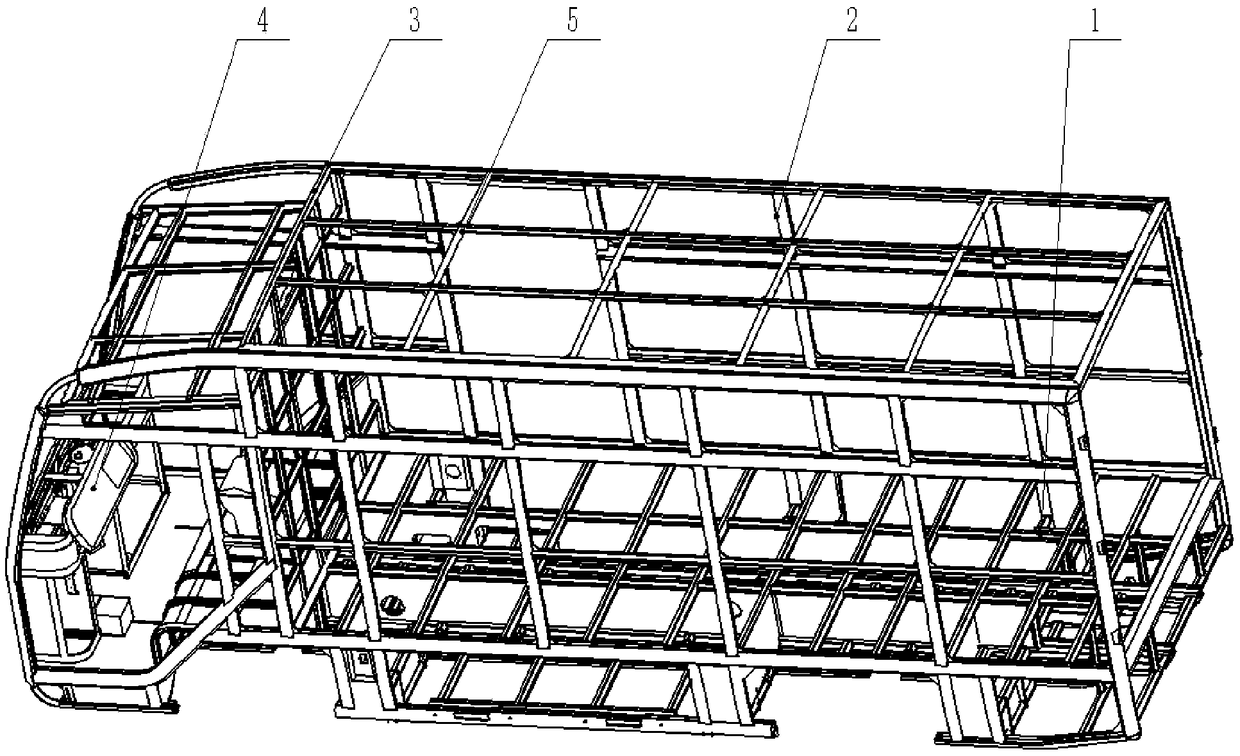

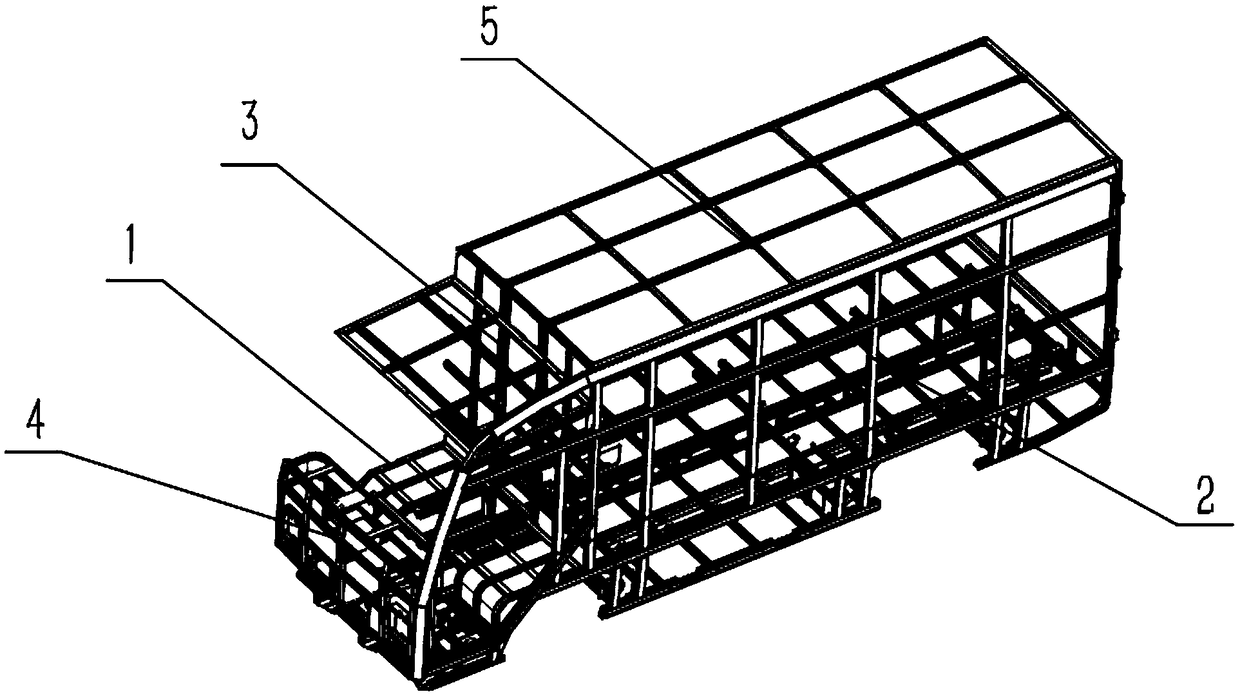

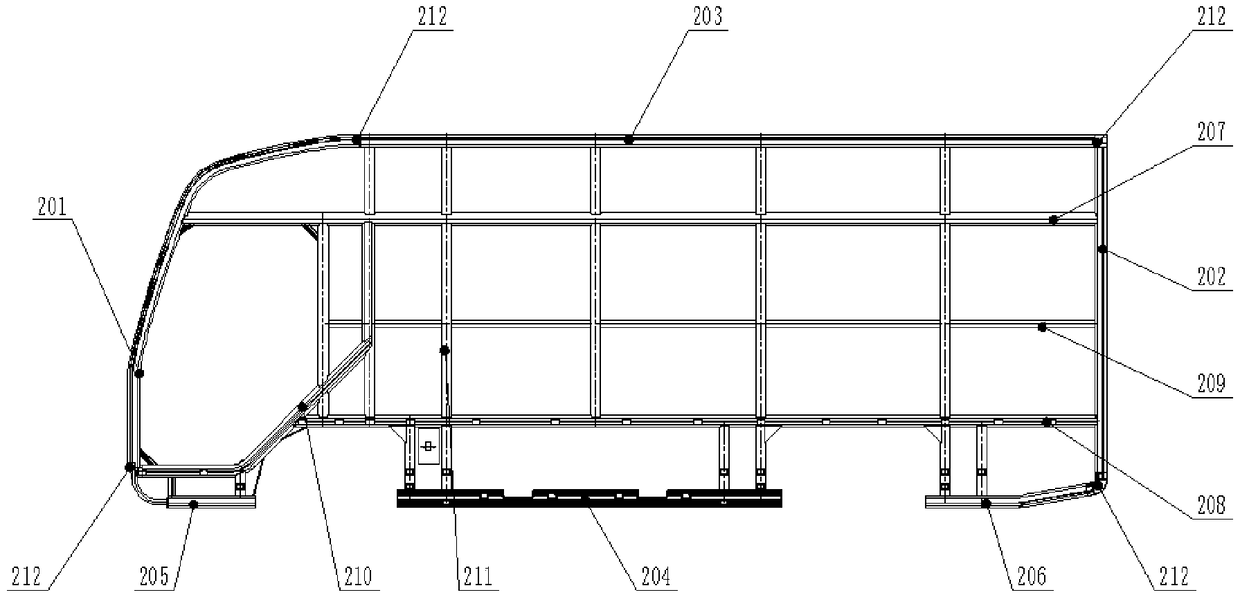

[0050] Please refer to figure 1 with figure 2 , in this embodiment, the whole vehicle structure of the logistics vehicle with full load bearing, modularization and full lightweight structure includes an aluminum alloy underframe structure 1, a side wall structure 2, a vertical partition structure 3, a front cabin instrument panel structure 4, and a ceiling Structure 5 and several connecting ribs. The aluminum alloy underframe structure 1 includes cross beams. The side wall structure 2 includes an outer frame top side beam 203 and an outer frame A-pillar 201 . The side wall structure 2 is connected with the beam by mortise and tenon. The ceiling structure 5 is screwed or tenon-tenon connected with the upper side beam 203 of the outer frame. The vertical partition structure 3 is respectively connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com